A method of converting crop stalks into gaseous fuel

A technology for crop straw and gaseous fuel, which is applied in the gasification process, the manufacture of combustible gas, the petroleum industry, etc., can solve the problems of environmental and air pollution, high cost of straw products, and impact on human life, so as to improve quality and avoid thermal deformation. Too large, reducing the effect of cleanup work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

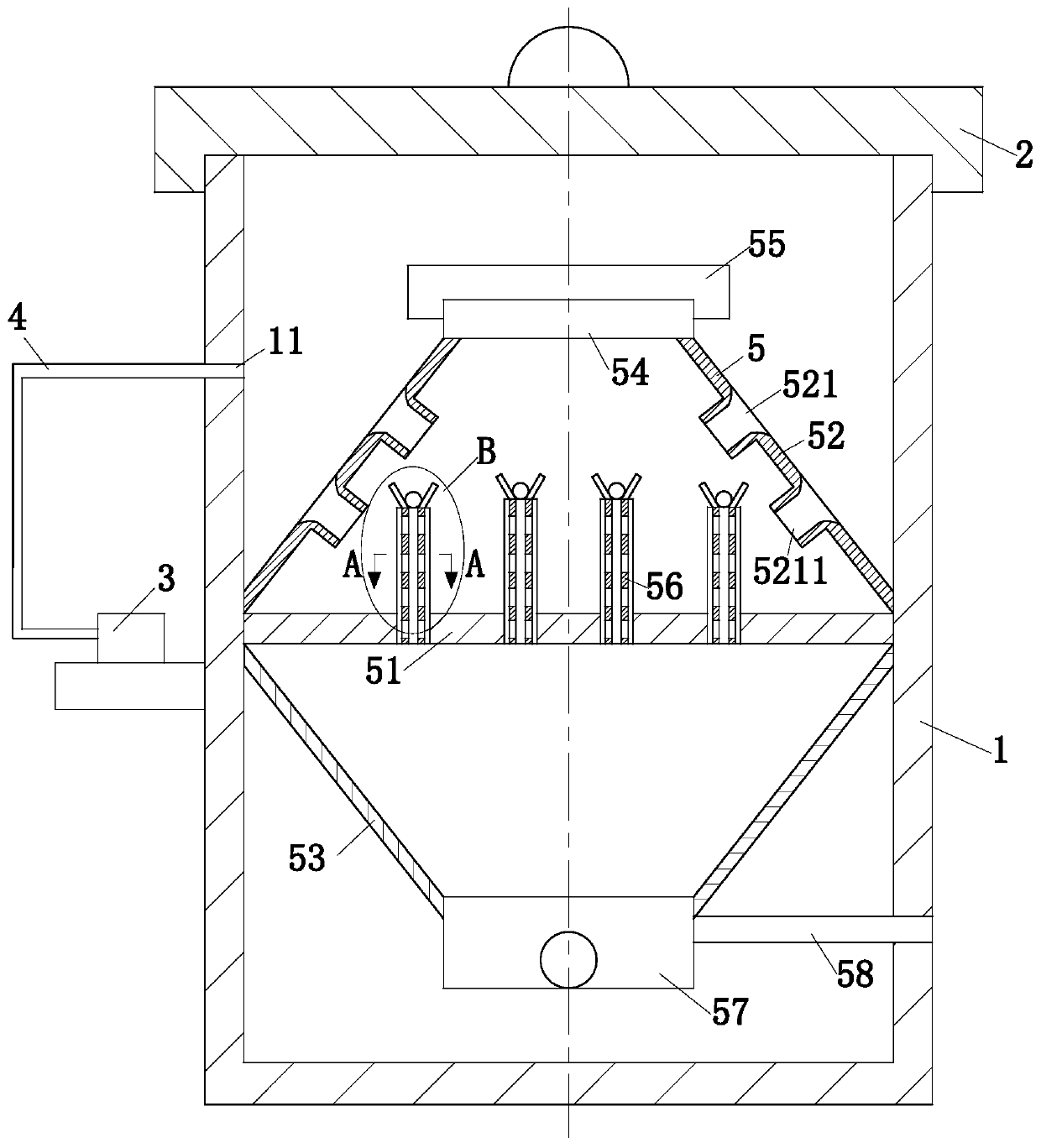

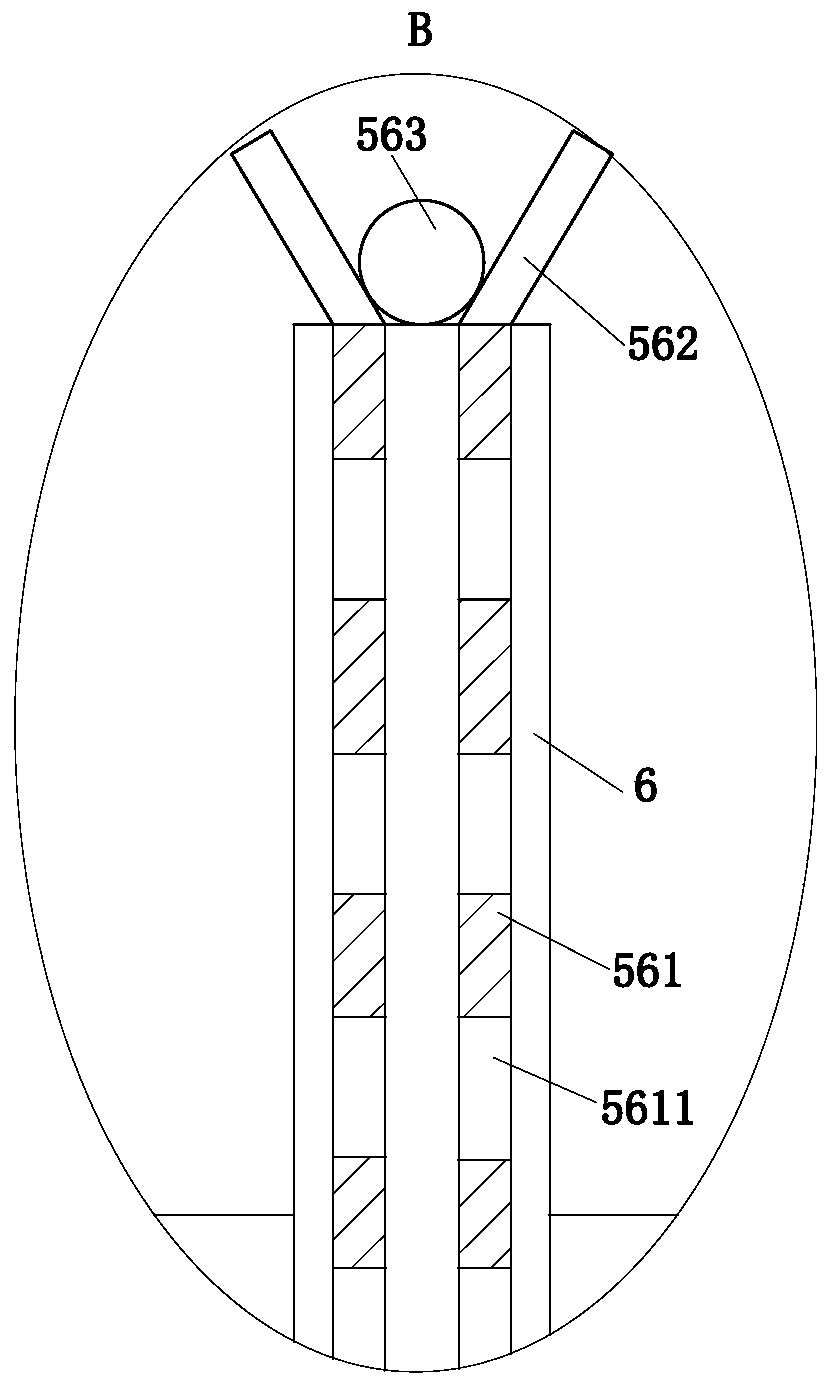

[0029] use Figure 1-Figure 5 The method for charging a new energy vehicle according to an embodiment of the present invention will be described as follows.

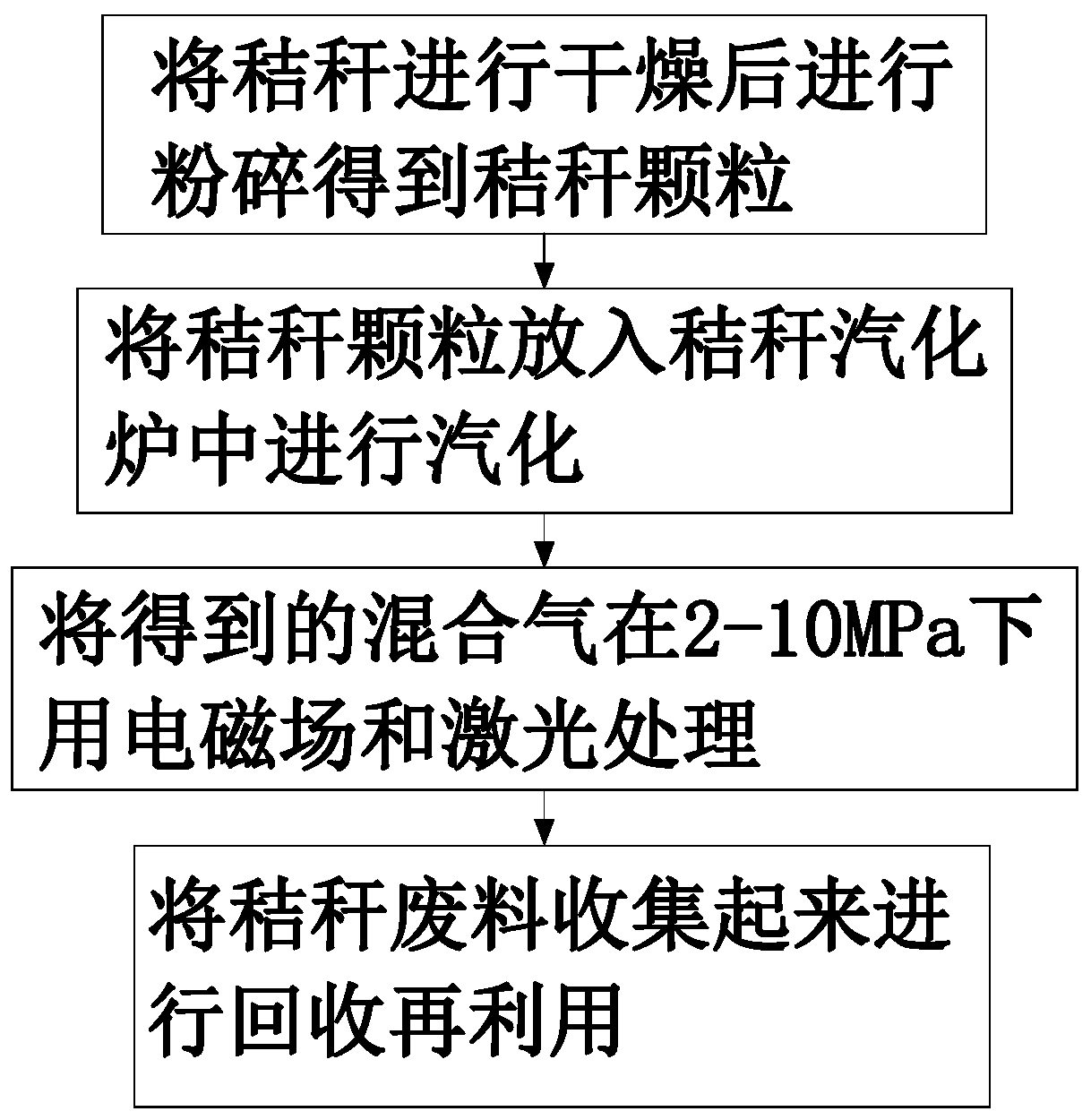

[0030] Such as figure 1 and figure 2 As shown, a method of converting crop stalks into gaseous fuel according to the present invention, the reduction method includes the following steps:

[0031] Step 1: drying the straw and putting it into a pulverizer for crushing to obtain straw particles;

[0032] Step 2: After the straw granules in step 1 are made, put the straw granules into a straw gasification furnace for vaporization to obtain mixed gas and straw waste;

[0033] Step 3: After the vaporization is completed, the mixed gas obtained in step 2 is treated with an electromagnetic field and a laser at 2-10 MPa to purify the mixed gas while eliminating the influence of the tar generated during the vaporization process on the straw gasification furnace;

[0034] Step 4: After the mixed gas in step 3 is processed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com