A stir-frying pot for grapefruit pressed oil

A cooking pot and pomelo technology, which is applied in the field of frying pots, can solve the problems of affecting oil quality, easy slag, and uneven stir-frying, so as to improve oil yield and oil quality, facilitate turning and discharging, and delay The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

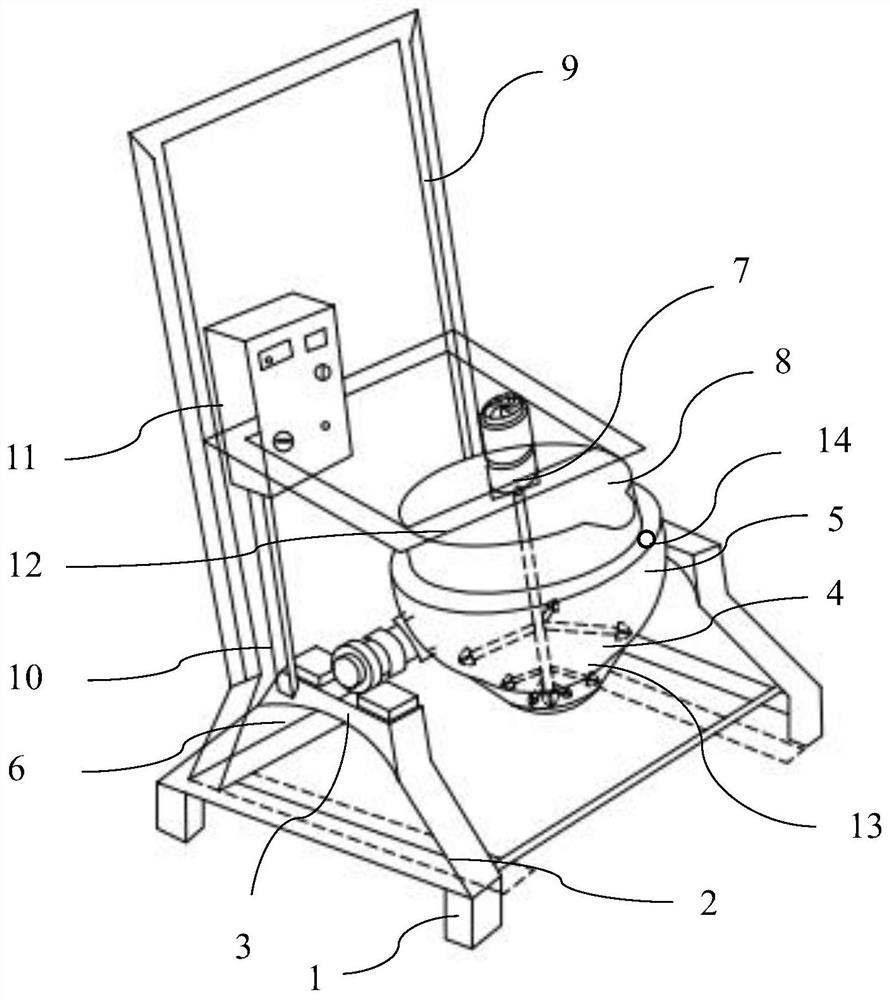

[0040] like Figure 1-2 As shown, a magepadial petroleum pot, including a fried cumshot pot body 4, a hand-shaped rotating shaft 3, an arch frame 2, a base 1, a stirring device, and a lifting device;

[0041] The fried cooker 4 has a sealed interlayer 5, which is filled with a heat transfer oil in the interlayer, and heats the fried cumshot pots 4 contents by heat transfer heat transfer;

[0042] The hand-shaped rotating shaft 3 is laterally welded to the outer wall of the fried cuvette 4 symmetrical, but does not penetrate the fry pot body 4, in addition, the hand-shaped rotating shaft 3 has external threads, and with a fry The pan 4 is maintained parallel;

[0043] The arch 2 is 2, and the top is provided with a groove, and the inside of the groove is provided with an internal thread that matches the hand-shaped rotating shaft 3, ie, the hand-shaped rotating shaft 3 can be placed in the recess. During the groove;

[0044] The hand-shaped rotating shaft 3 is placed in the groove o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com