Solar thermal utilization system combined with gas-steam combined cycle

A combined cycle, solar thermal technology applied in the field of solar thermal utilization systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

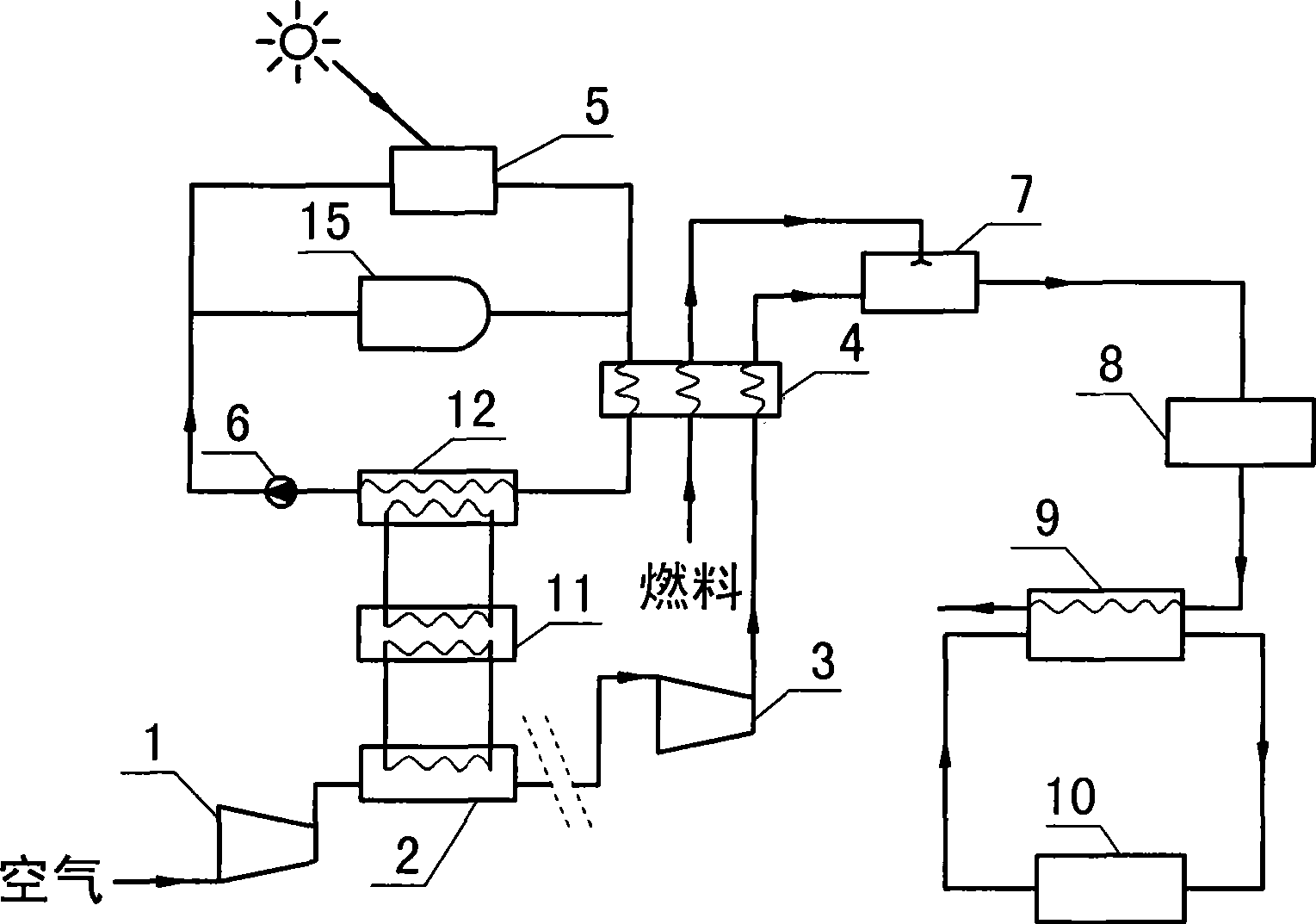

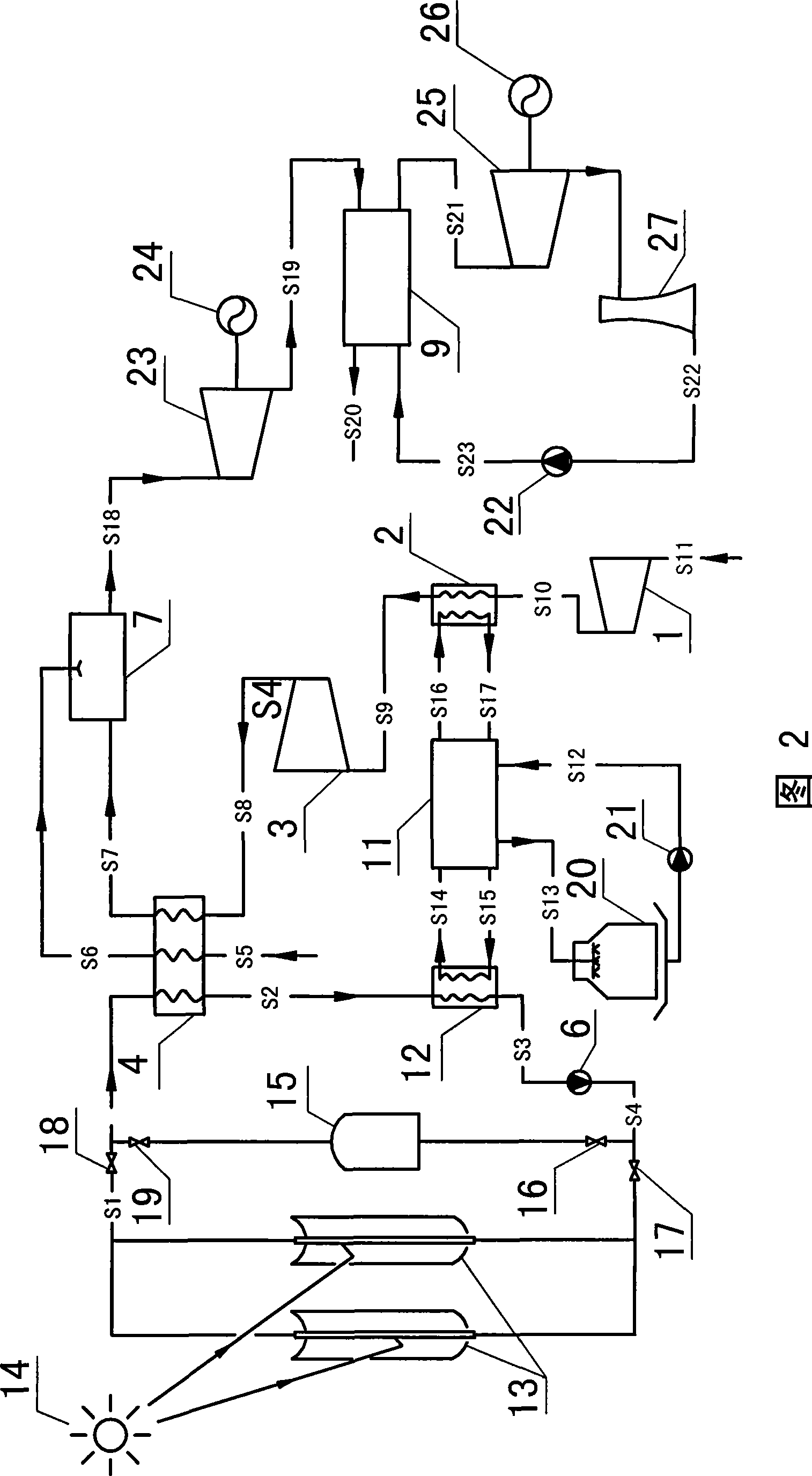

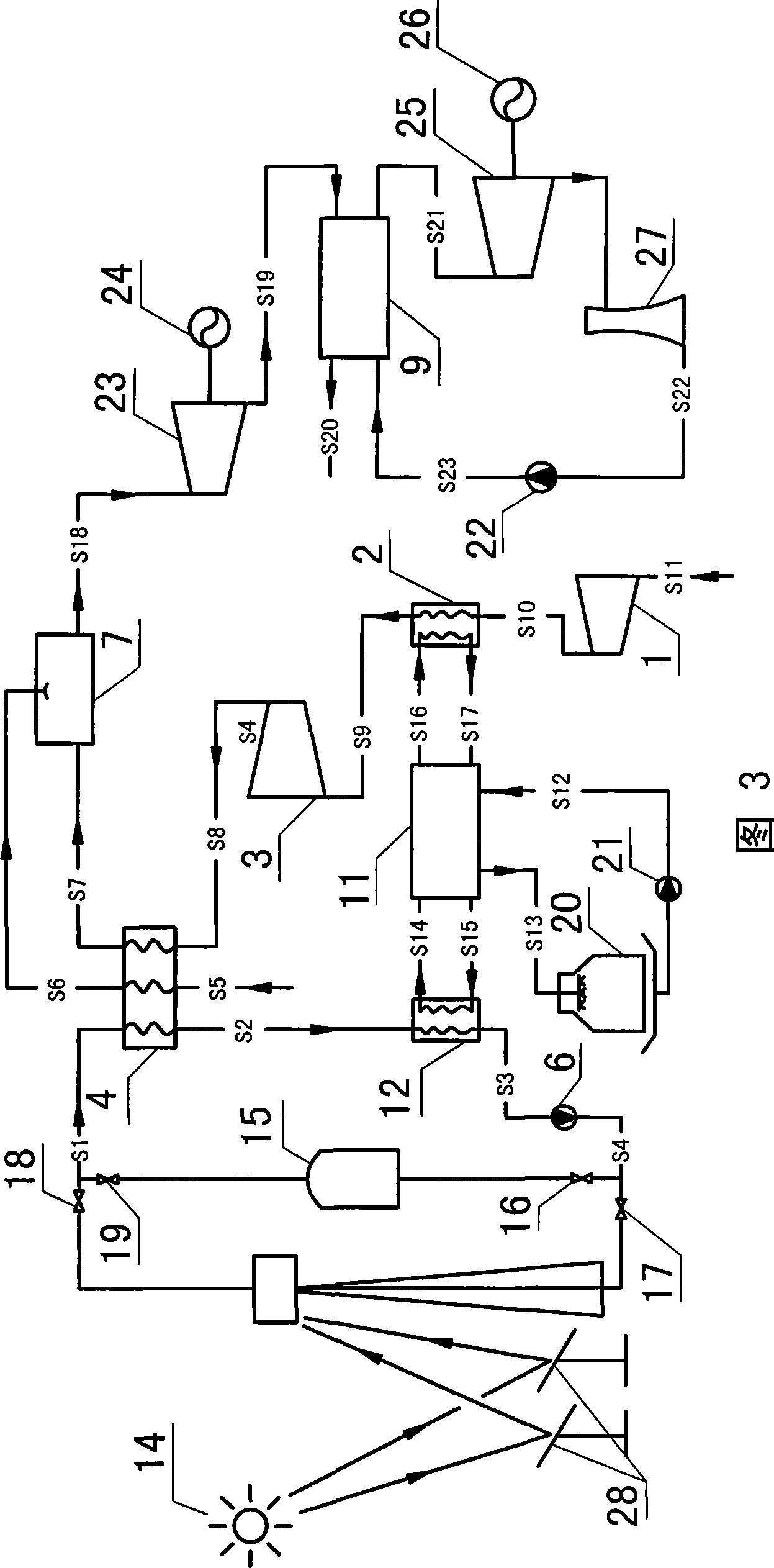

[0034] Embodiment 1 of the present invention. The solar heat utilization system combined with the gas-steam combined cycle proposed by the present invention includes a solar energy concentrating heat collection subsystem, a refrigeration subsystem, a heat exchange and heat storage device, and a gas-steam combined cycle power subsystem; a heat exchange device Including high temperature heat exchanger and low temperature heat exchanger. The solar concentrating heat collection subsystem is used to receive and gather solar radiation energy, and convert the received solar radiation energy into heat energy of the heat medium; the heat storage device is not only used to store the surplus energy output by the solar concentrating heat collection subsystem , and continue to provide thermal energy to the heat exchange device when the solar radiation is insufficient; the energy output by the solar concentrating heat collection subsystem first heats the final stage outlet air of the multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com