Design method and system for heat dissipation and ventilation parameters of reactor hall

A design method and reactor technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as air temperature cannot be too high, heat dissipation efficiency is low, and parameters are too many.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

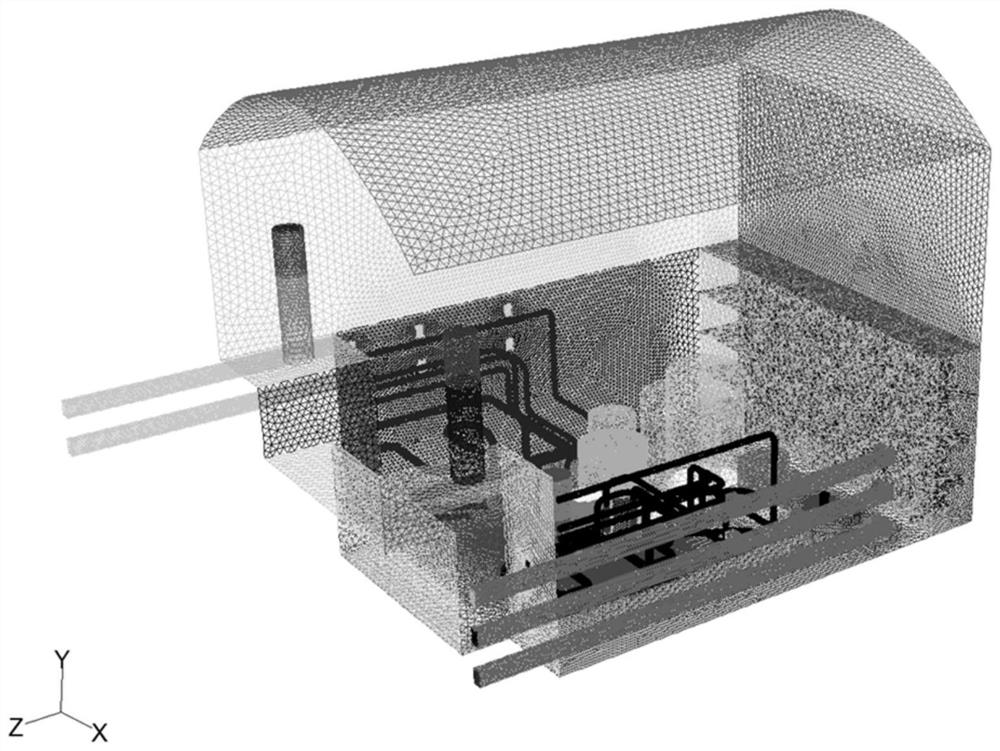

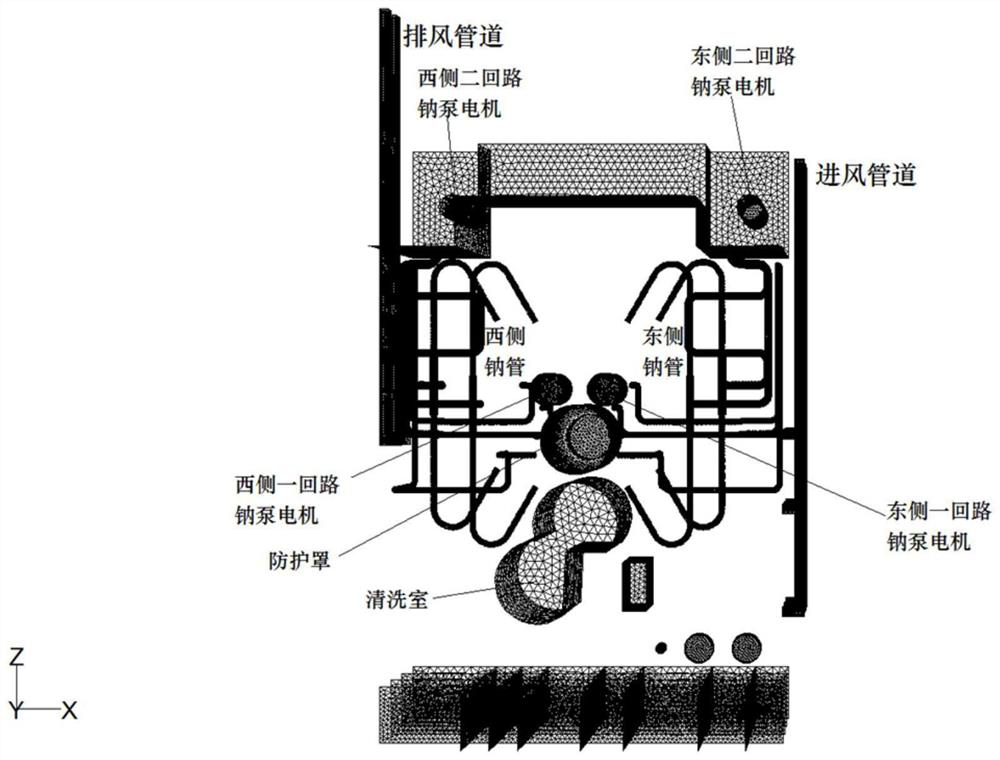

[0106] like figure 1 and figure 2 As shown, the main equipment in the reactor hall includes: primary circuit sodium pump motor, secondary circuit sodium pump motor, equipment preheating trap, slender equipment cleaning container, large and medium-sized equipment cleaning container, new components, loader, and in-plant transportation barrel Wait.

[0107] This embodiment provides a method for designing the heat dissipation and ventilation parameters of the reactor hall, including:

[0108] S1: According to the structural parameters of the ventilation system, the reactor hall, and the main heat dissipation equipment in the reactor hall, establish the fluid domain model inside the reactor hall.

[0109] The structural parameters include:

[0110] (1) The size parameters of the reactor hall, and the size of the main buildings in the hall;

[0111] (2) The distribution and size of sodium pumps and sodium pipelines;

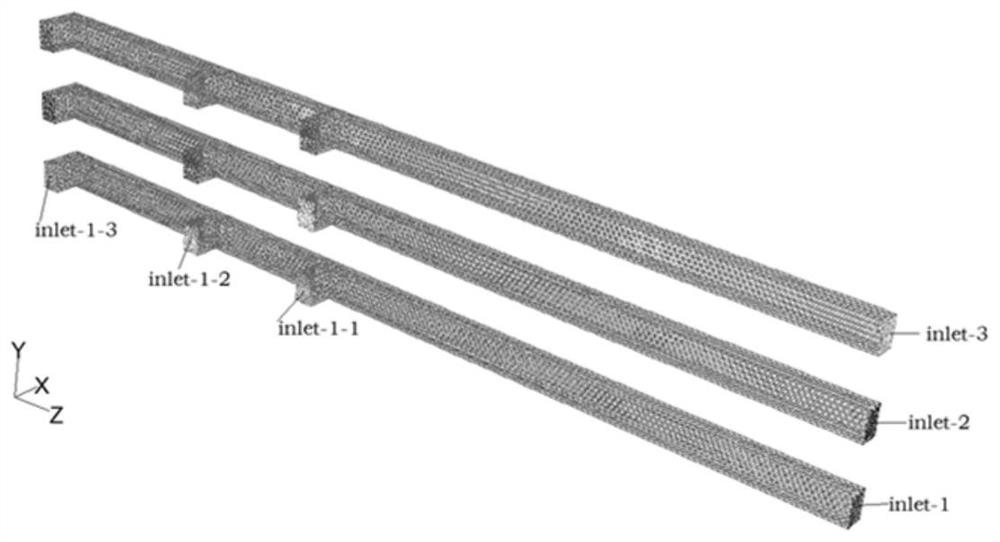

[0112] (3) The layout and size of the air supply duct, the ...

Embodiment 2

[0180] like Figure 11 As shown, this embodiment provides a system for implementing the method for designing heat dissipation and ventilation parameters of the reactor hall in Embodiment 13, including: a model building module, a grid discretization module, a simulation analysis module, a calculation module, a judgment module and an execution module,

[0181] The model building module is used to establish the fluid domain model inside the reactor hall according to the structural parameters of the ventilation system, the reactor hall, and the main cooling equipment in the reactor hall;

[0182] The grid discretization module is connected with the model building module, and is used for grid discretization of the fluid domain model;

[0183] The simulation analysis module is connected with the grid discretization module, and is used to simulate and analyze the grid model for different hall air supply volumes according to the given fluid domain parameters including the heat dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com