Built-in engine sump tank heater

An engine oil, built-in technology, used in oil pans, engine components, machines/engines, etc., can solve the problems of limited heating area, poor heating effect, and small size of the heater, so as to improve heating efficiency and facilitate smooth operation. Activate, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

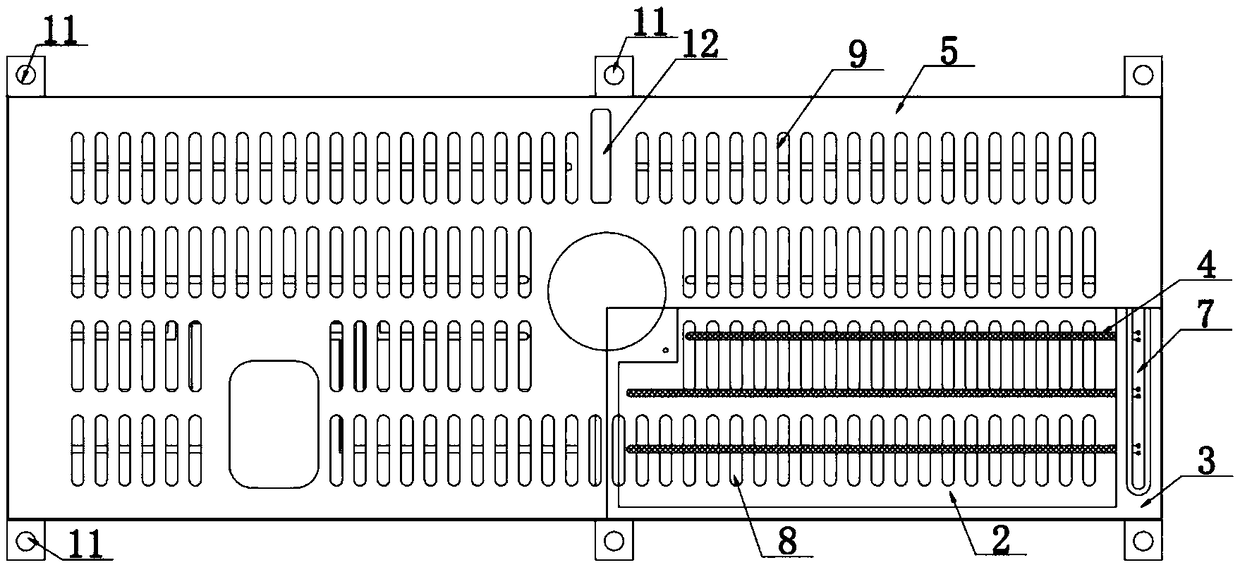

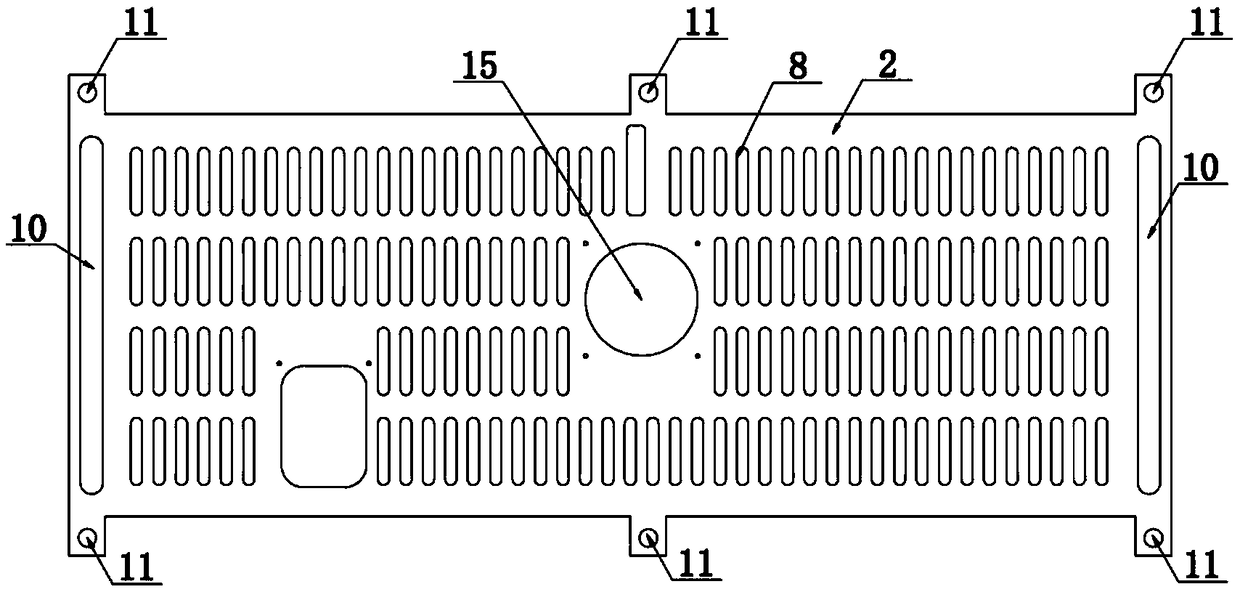

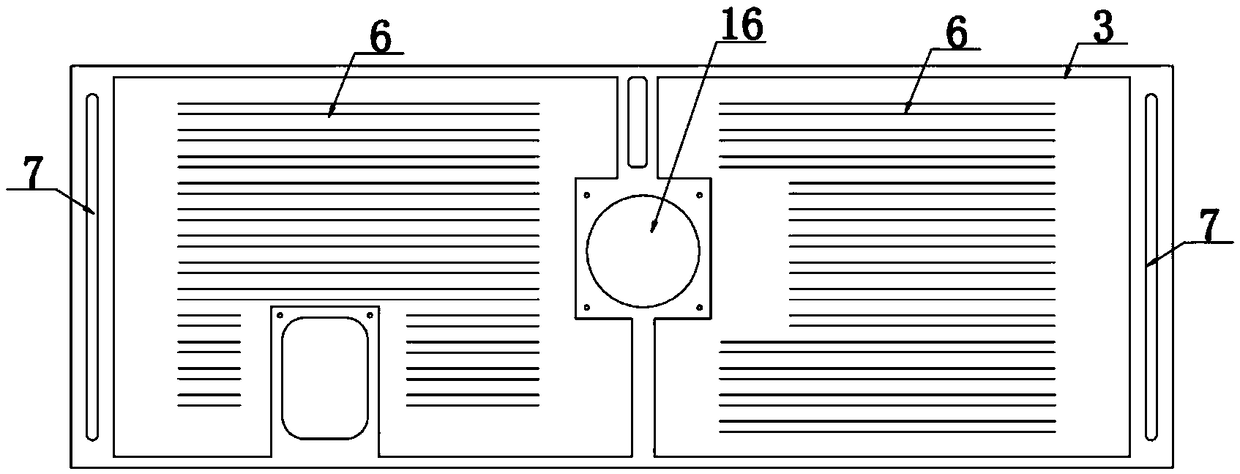

[0040] like Figure 1-7 As shown, a built-in engine oil pan heater includes a heating plate arranged in the oil pan, the heating plate includes a bottom plate 2, an inner tank 3, a heating element 4 and a cover plate 5, and the heating element is installed On the inner container, the inner container is arranged between the bottom plate and the cover plate, and the two ends of the inner container are provided with wiring boards 7 for connecting the heating element with a power supply.

[0041] The heating element can adopt a heating wire whose publication number is CN102281655A. This heating wire is not only safe to use, not easy to wear, ensures the heating effect of fuel oil, but also saves electric energy and is more environmentally friendly.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com