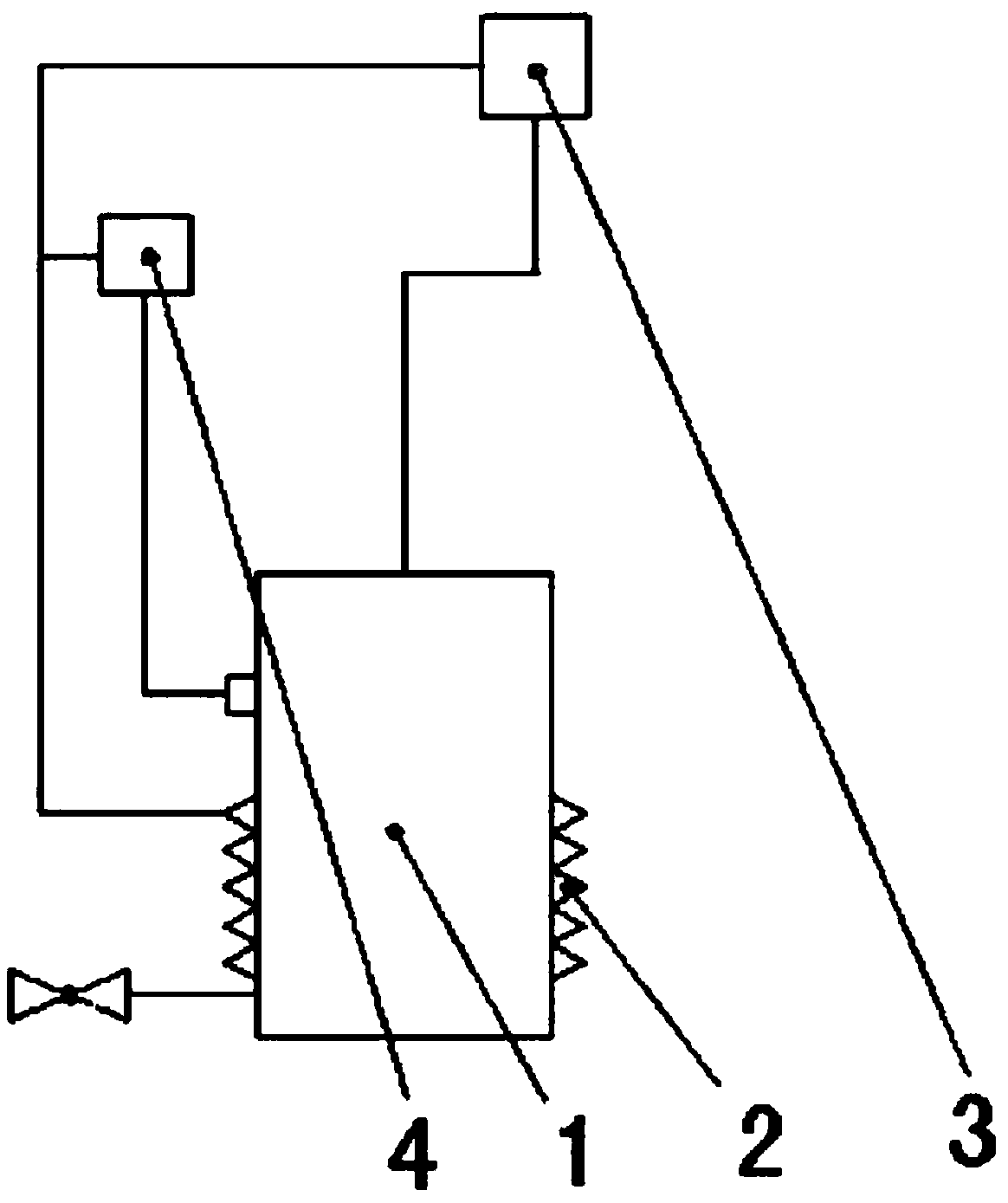

Liquid storage tank with resistance heater

A resistance heater and liquid storage tank technology, applied in the field of liquid storage tanks, can solve problems such as unfavorable temperature protectors and achieve smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

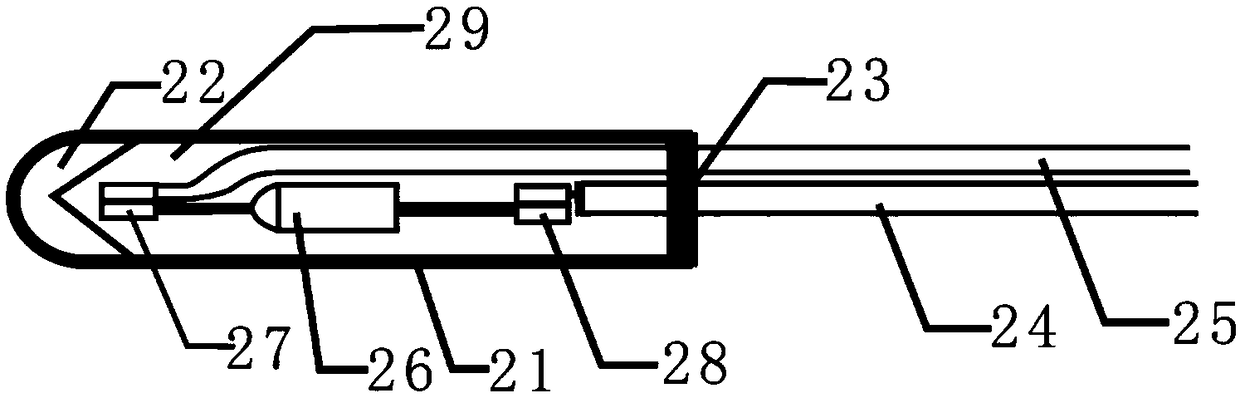

[0033] In this embodiment, the temperature protector includes a shell, the ports of the shell are sealed, a thermal fuse is arranged inside the shell, and the thermal fuse is electrically connected to an insulated wire through a terminal; and a moisture-absorbing filler is arranged inside the shell, and the moisture-absorbing filler is polyester fiber.

[0034] The preparation process of the polyester fiber is as follows:

[0035] S1. Modified copolyester chips are prepared by in-situ polymerization by adding hollow glass beads and activated bentonite;

[0036] S2. The modified copolyester chips are prepared by melt spinning to obtain polyester fibers.

[0037] Among them, S1 is specifically:

[0038] Take the bentonite and heat it at 340°C for 50min, where the heating rate is 3°C / min; then continue to heat up to 490°C for 10h, where the temperature rise rate is 5°C / min; naturally cool down; put the heated bentonite in Soak in sodium hydroxide solution for 10 hours, clean with distill...

Embodiment 2

[0044] In this embodiment, the temperature protector includes a shell, the ports of the shell are sealed, a thermal fuse is arranged inside the shell, and the thermal fuse is electrically connected to an insulated wire through a terminal; and a moisture-absorbing filler is arranged inside the shell, and the moisture-absorbing filler is polyester fiber.

[0045] The preparation process of the polyester fiber is as follows:

[0046] S1. Modified copolyester chips are prepared by in-situ polymerization by adding hollow glass beads and activated bentonite;

[0047] S2. The modified copolyester chips are prepared by melt spinning to obtain polyester fibers.

[0048] Among them, S1 is specifically:

[0049] Take the bentonite and heat it at 340°C for 50min, where the heating rate is 3°C / min; then continue to heat up to 490°C for 10h, where the temperature rise rate is 5°C / min; naturally cool down; put the heated bentonite in Soak in sodium hydroxide solution for 10 hours, clean with distill...

Embodiment 3

[0055] In this embodiment, the temperature protector includes a shell, the ports of the shell are sealed, a thermal fuse is arranged inside the shell, and the thermal fuse is electrically connected to an insulated wire through a terminal; and a moisture-absorbing filler is arranged inside the shell, and the moisture-absorbing filler is polyester fiber.

[0056] The preparation process of the polyester fiber is as follows:

[0057] S1. Modified copolyester chips are prepared by in-situ polymerization by adding hollow glass beads and activated bentonite;

[0058] S2. The modified copolyester chips are prepared by melt spinning to obtain polyester fibers.

[0059] Among them, S1 is specifically:

[0060] Take the bentonite and heat it at 340°C for 50min, where the heating rate is 3°C / min; then continue to heat up to 490°C for 10h, where the temperature rise rate is 5°C / min; naturally cool down; put the heated bentonite in Soak in sodium hydroxide solution for 10 hours, clean with distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com