Multi-point layered grain detection rod

A technology for detecting rods and grain conditions, applied in the field of multi-point layered grain condition detection devices, can solve the problems of difficult maintenance, complicated signal lines, inability to detect the number and temperature of pests, etc., to reduce the number of signals, high detection efficiency, Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

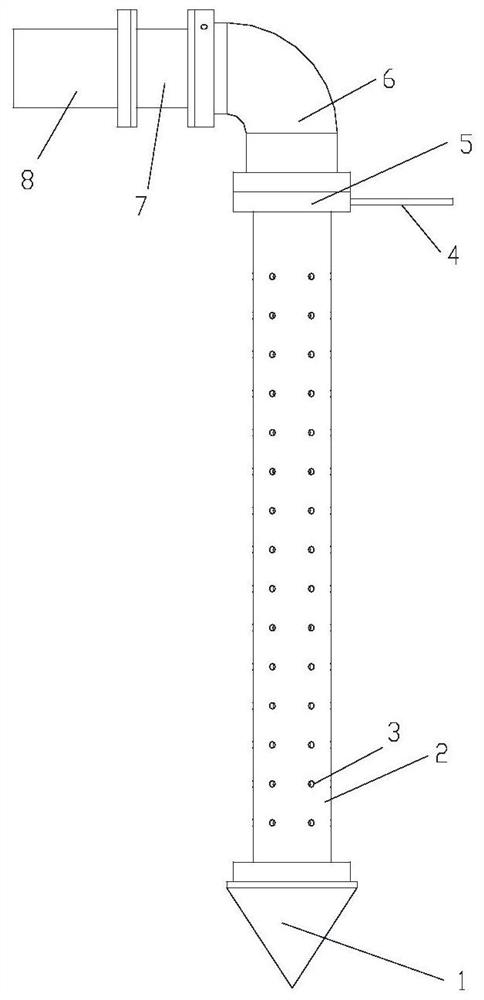

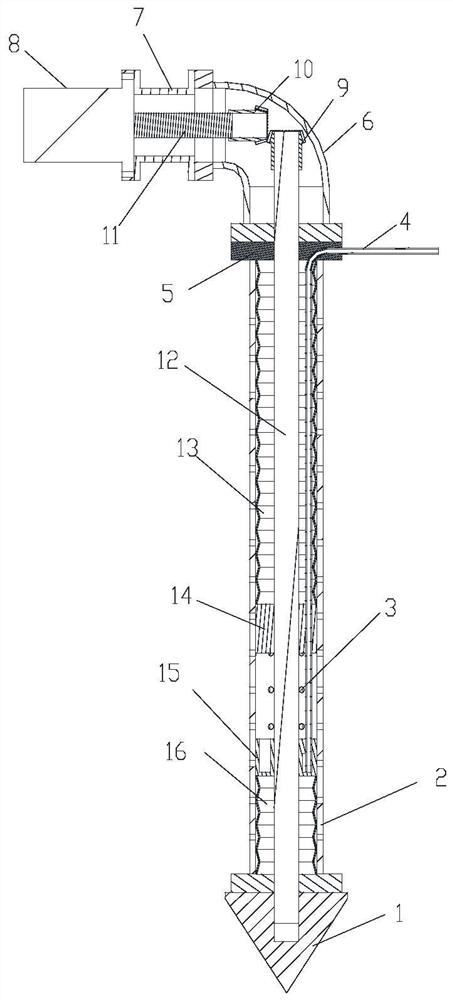

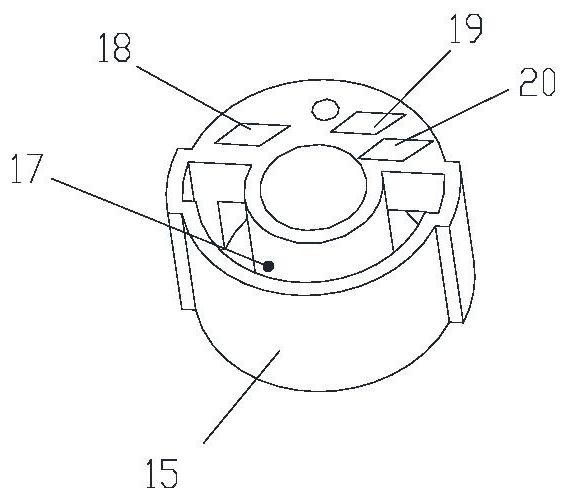

[0020] Such as Figure 1-4 Shown: a multi-point layered grain situation detection rod in this embodiment, comprising a hollow insect trapping tube 2 and an insect pumping tube 4, the tube wall of the insect trapping tube 2 is provided with a trapping hole 3, and Comprising an upper folded tube 13, a traction block 14, an insect collector 15 and a lower folded tube 16 arranged sequentially from top to bottom within the insect trap 2, the outer walls of the upper folded tube 13 and the lower folded tube 16 are all aligned with the insect trap. 2, the inner wall of the traction block 14 is attached to the upper end surface of the insect trap 15, and the traction block 14 and the insect trap 15 are respectively connected to the upper folding pipe 13 and the lower folding pipe 16. ; The insect trapping tube 2 is also provided with a driving device for driving the traction block 14 and the insect trap 15 while sliding along the axial direction of the insect trapping tube 2 with a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com