Steel deck pavement interlayer shear test simulation method based on discrete element

A technology of shear test and simulation method, which is applied in the field of steel bridge deck pavement engineering, and can solve the problems of not considering the interface between layers, stress concentration in the failure path, and adverse effects on the shear resistance performance of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for simulating shear tests between layers of steel bridge deck pavement based on discrete elements comprises the following steps:

[0042] Step 1: Use the "wall" command in the PFC3D software to generate a given asphalt pavement area, and put coarse aggregate particles 1 in the asphalt pavement area according to the coarse aggregate particle 1 model construction method;

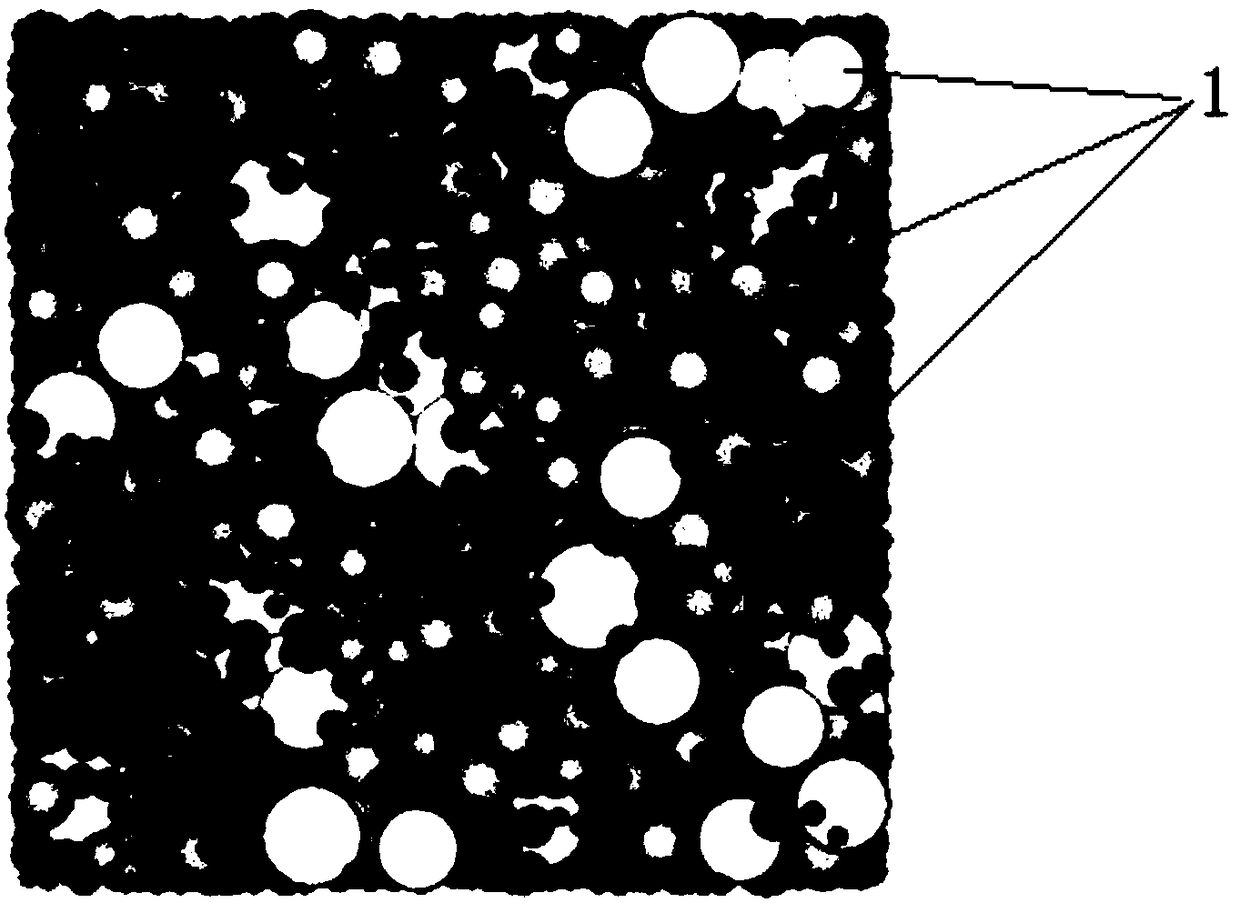

[0043] Step 2: In the area of the asphalt pavement layer in a rectangular arrangement, several coarse aggregate particles are regularly generated to fill the entire area, and the FISH programming is used to determine whether the particle unit belongs to the coarse aggregate particle 1, and if so, identify it as Coarse aggregate particle 1, otherwise it is identified as asphalt mortar particle 2, and according to the construction method of the void model, the asphalt mortar particle 2 is deleted to form the void unit of the asphalt pavement layer, thereby generating the asphalt pavement model,...

Embodiment 2

[0049] Taking the interlayer shear of the steel bridge deck pavement of asphalt mixture AC-10 as an example, the implementation steps of the present invention are described in detail in conjunction with the accompanying drawings. The gradation of asphalt mixture AC-10 is shown in Table 1.

[0050] Table 1 Grading table of asphalt mixture AC-10

[0051] Mesh size / mm

13.2

9.5

4.75

2.36

1.16

0.6

0.3

0.15

0.075

Passing rate / %

100

92

71

39

22.5

17

12.5

8.5

6

[0052] The specific modeling process of steel bridge deck pavement composite specimen is as follows:

[0053] 1) Determination of the space area

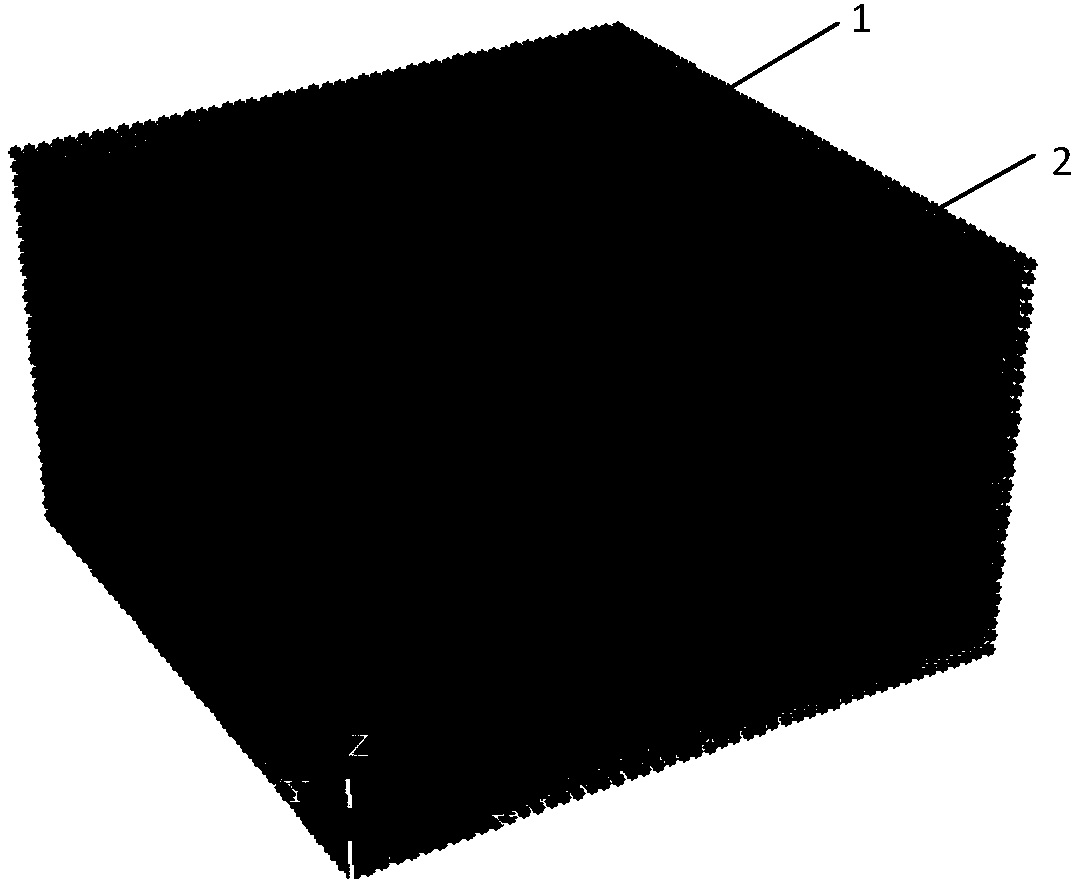

[0054] According to the actual size of the indoor test model, the size of the asphalt pavement area is 95mm×95mm×60mm, the size of the steel plate area is 95mm×95mm×10mm, and the two areas are closely connected, such as figure 1 shown.

[0055] 2) Generation of asphalt mixture coarse aggregate particles,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com