Paddy rice soilless seedling raising substrate formula, soilless seedling raising substrate block and preparation method thereof

A soilless seedling raising and paddy rice technology, which is applied in the field of rice seedling raising, can solve the problems of inappropriate rice growth requirements, poor water retention, and nutritional imbalance, and achieve the effects of being suitable for industrial production, good water retention, and long-lasting fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The invention also provides a preparation method of the soilless rice seedling raising matrix hole block, comprising: adding water and mixing the raw materials of the rice soilless seedling raising matrix formula, and then forming them.

[0062] Specifically, the anti-mold agent, flocculant, rice seedling strengthening agent, bentonite and degradable amino acid water-absorbing resin are added in the form of the first mixture. The anti-mold agent, flocculant, rice seedling-strengthening agent, bentonite and degradable amino acid water-absorbing resin are sequentially added to the mixer, fully stirred to obtain the first mixture.

[0063] The second mixture is obtained by mixing various raw material powders such as rice straw powder and rice husk powder in the biomass organic raw material powder.

[0064] Mix the binder and water at a mass ratio of 1:18-22, for example 1:20, to obtain a mixed solution. Add the first mixed material into the second mixed material and stir ...

Embodiment 1-5

[0068] A method for preparing a soilless rice seedling raising matrix hole block, comprising:

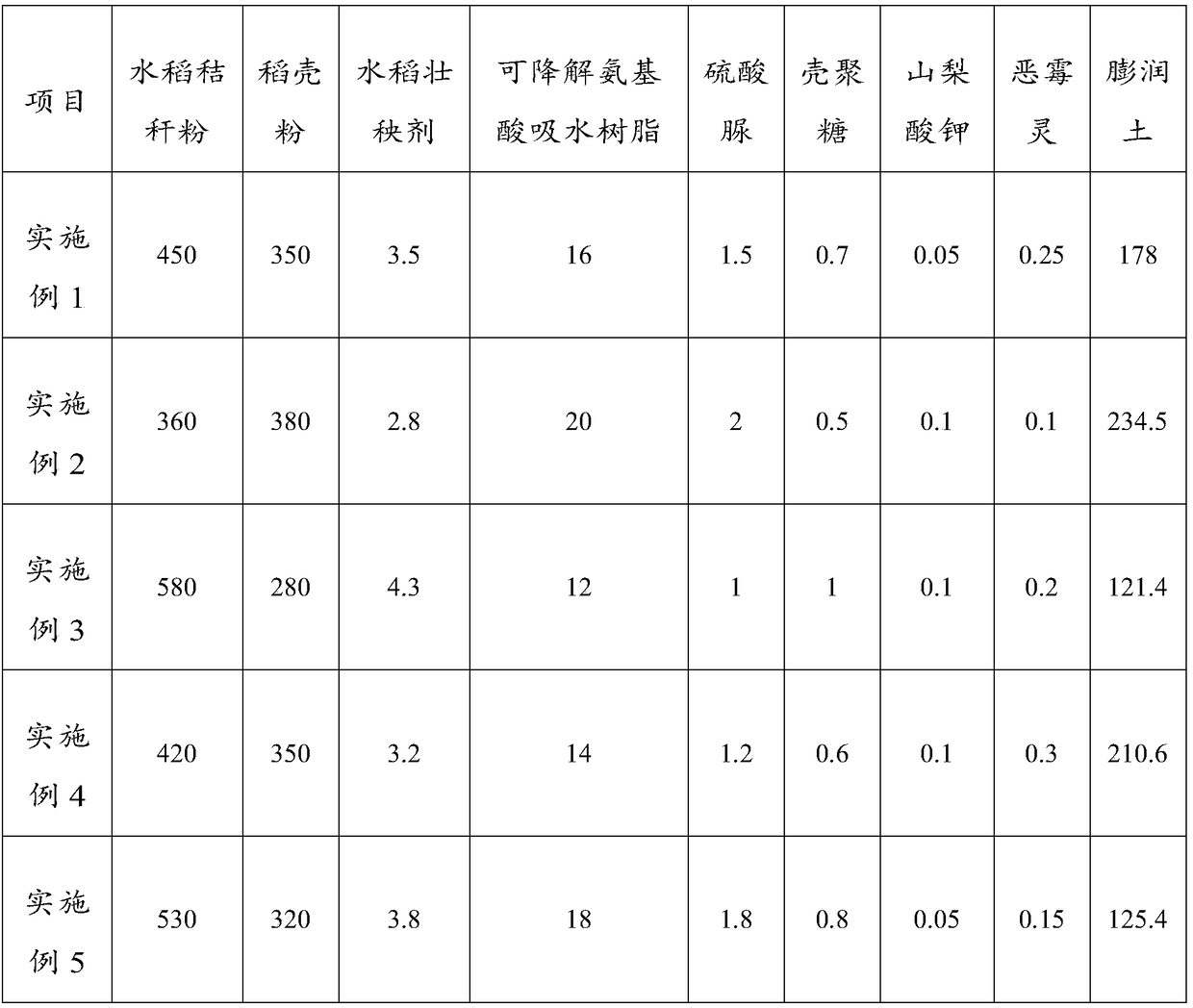

[0069] S1. Prepare raw materials according to the formula of rice soilless seedling raising matrix, the raw materials include: rice straw powder, rice husk powder, rice seedling strengthening agent, degradable amino acid water-absorbing resin, urea sulfate, chitosan, potassium sorbate, hymexazol and Bentonite. The content of each component in the raw material is shown in Table 1.

[0070] S2. Potassium sorbate, hymexazol, chitosan, rice seedling strengthening agent, bentonite and degradable amino acid water-absorbing resin are sequentially added to the mixer, and the mixture is thoroughly stirred to obtain the first mixture.

[0071] S3, uniformly mixing the rice straw powder crushed to 3-5mm and the rice husk powder crushed to 2-3mm to obtain a second mixture.

[0072] S4. Mix urea sulfate and water at a mass ratio of 1:20 to obtain a third mixture.

[0073] S5. Add the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com