Method for preparing tobacco extract microcapsule through supercutical fluid

A technology of tobacco extract and supercritical flow, applied in the field of tobacco, can solve the problems of ineffective wrapping of nicotine, lack of active ingredients, and long operation time, so as to shorten the preparation time, improve the taste and satisfaction of smoking, and simplify the process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

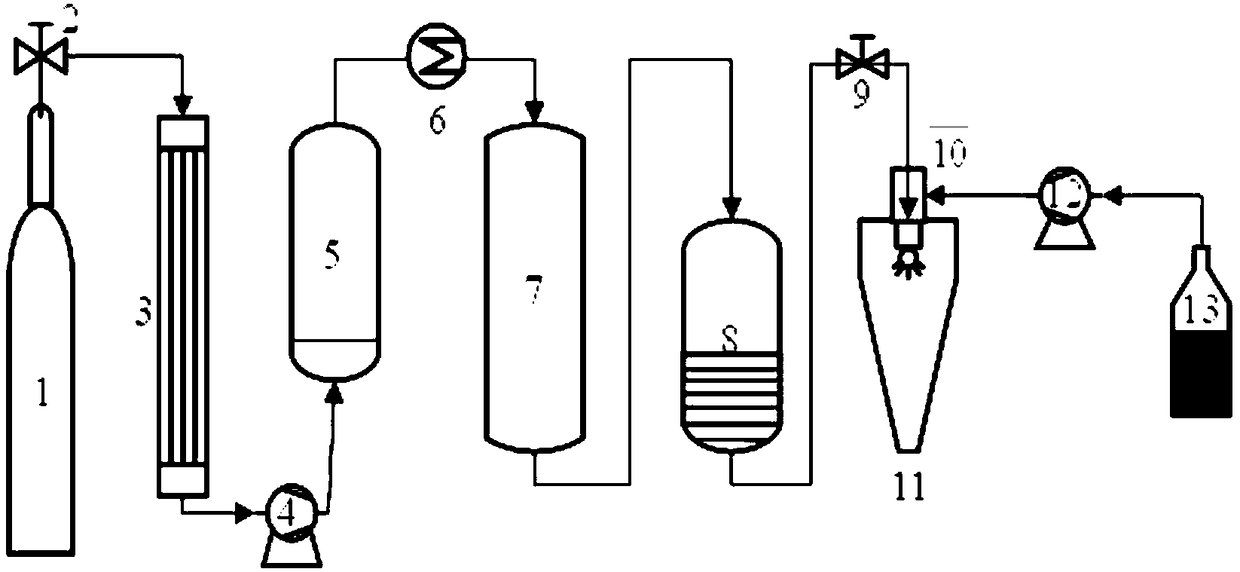

Method used

Image

Examples

Embodiment 1

[0024] (1) 1000g burley tobacco is packed into the extraction kettle, and the 2 Under the supercritical state, for extraction, supercritical CO 2 The extraction conditions are as follows: extraction temperature is 40°C, extraction pressure is 15MPa, CO 2 The flow rate is 40L / h.

[0025] (2) The extract in the separation tank and the wall material solution are transported to the coaxial nozzle arranged on the top of the spray drying tower, at the outlet of the coaxial nozzle, the tobacco extract and the wall material solution are mixed and emulsified, and then sprayed down, Heat and dry to obtain microcapsules of tobacco extract.

[0026] In the wall material solution, the weight content of the wall material is 25%, wherein, the weight content of gum arabic is 10%, maltodextrin 5%, sodium alginate 5%, sodium carboxymethyl cellulose 5%; The weight content is 0.2%, wherein, monoglyceride is 0.1%, and Tween is 0.1%.

[0027] The volume of the emulsion is 20 times that of the e...

Embodiment 2

[0031] (1) 1000g burley tobacco is packed into the extraction kettle, and the 2 Under the supercritical state, for extraction, supercritical CO 2 The extraction conditions are as follows: extraction temperature is 45°C, extraction pressure is 20MPa, CO 2 The flow rate is 50L / h.

[0032] (2) The extract in the separation tank and the wall material solution are transported to the coaxial nozzle arranged on the top of the spray drying tower, at the outlet of the coaxial nozzle, the tobacco extract and the wall material solution are mixed and emulsified, and then sprayed down, Heat and dry to obtain microcapsules of tobacco extract.

[0033] In the wall material solution, the weight content of the wall material is 30%, wherein, the weight content of gum arabic is 10%, maltodextrin 10%, sodium alginate 5%, sodium carboxymethyl cellulose 5%; The weight content is 0.6%, wherein, monoglyceride is 0.2%, soybean protein isolate is 0.2%, and Tween is 0.2%.

[0034] The volume of the ...

Embodiment 3

[0038] (1) 1000g burley tobacco is packed into the extraction kettle, and the 2 Under the supercritical state, for extraction, supercritical CO 2 The reaction conditions are as follows: extraction temperature is 50°C, extraction pressure is 25MPa, CO 2 The flow rate is 60L / h.

[0039] (2) The extract in the separation tank and the wall material solution are transported to the coaxial nozzle arranged on the top of the spray drying tower, at the outlet of the coaxial nozzle, the tobacco extract and the wall material solution are mixed and emulsified, and then sprayed down, Heat and dry to obtain microcapsules of tobacco extract.

[0040] In the wall material solution, the weight content of the wall material is 35%, wherein, the weight content of gum arabic is 15%, maltodextrin 10%, sodium alginate 10%; the weight content of emulsifier is 0.6%, wherein, the single Glyceride 0.2%, soybean protein isolate 0.2%, Tween 0.2%.

[0041] The volume of the emulsion is 30 times that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com