Double-alkali desulfurization and dedusting recycling device and method thereof

A technology of desulfurization and dust removal and double alkali method, which is applied in the direction of separation methods, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve problems such as expensive treatment costs, difficult to handle and utilize desulfurization products, and blockage of pipelines, etc., to achieve reduction Cost, prevention of pipe clogging, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

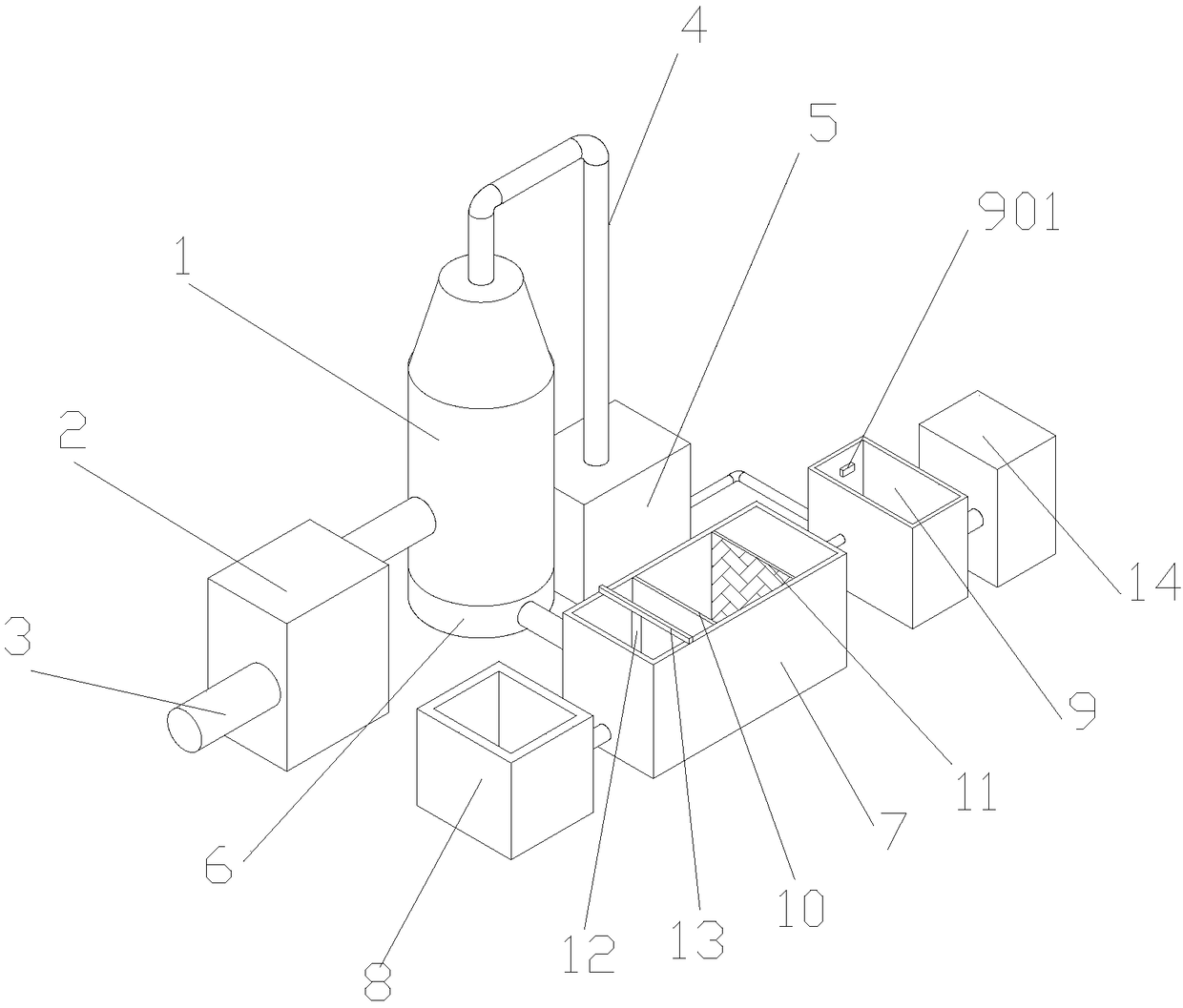

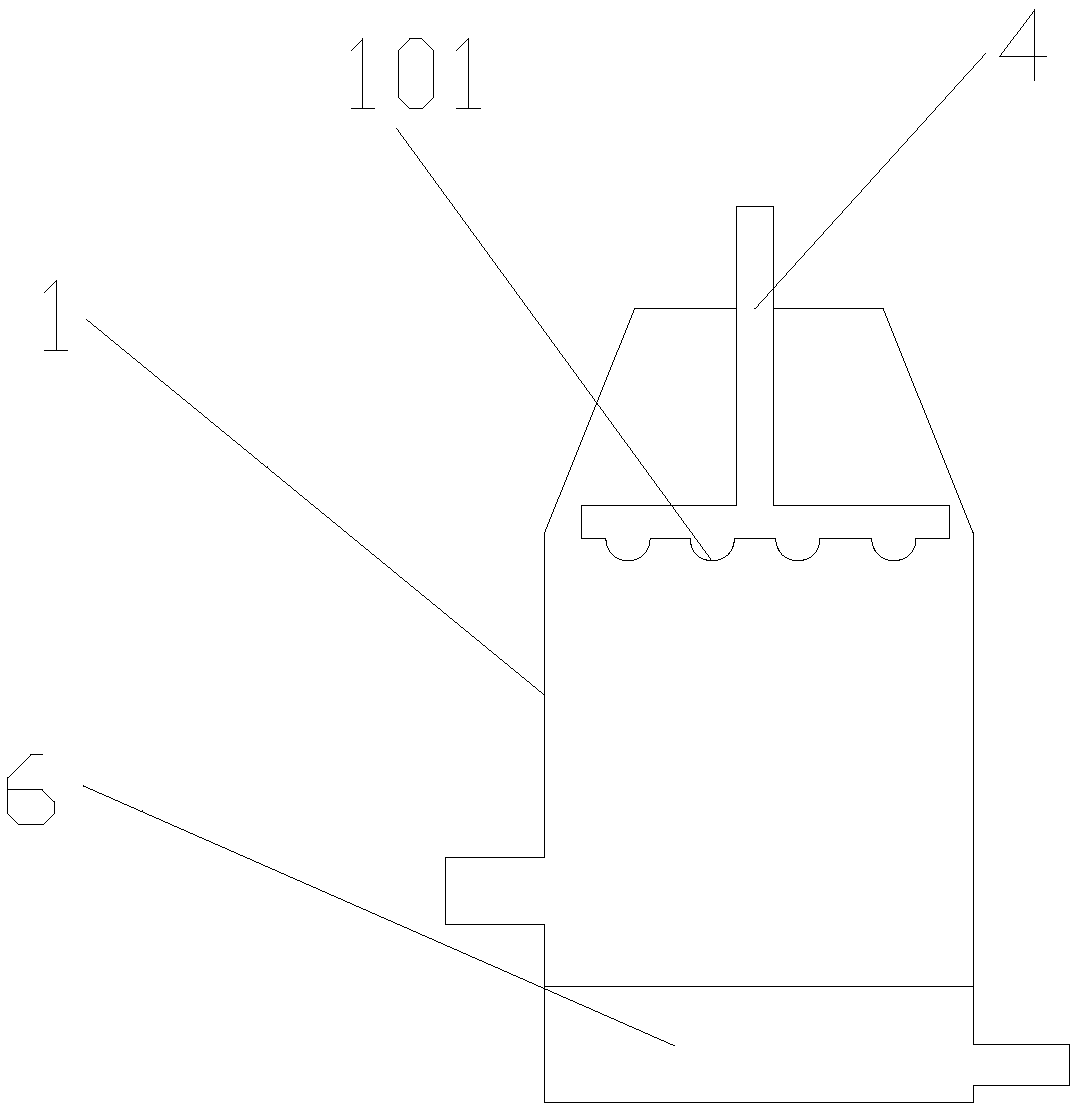

[0021] Such as Figure 1-3 As shown, a dual-alkali method desulfurization and dust removal recycling device includes a desulfurization tower 1, the desulfurization tower 1 is connected to the dust removal chamber 2, the dust removal chamber 2 is connected to the flue gas inlet 3, and a nozzle 101 is arranged on the top of the desulfurization tower 1, and the nozzle 101 is connected through a water pipe 4 Sodium hydroxide box 5, a solution recovery pool 6 is set at the bottom of the spray tower 1, and the solution recovery pool 6 is connected to the reaction pool 7, and the reaction pool 7 is connected to the calcium hydroxide box 8 and the treatment box 9, and the treatment box 9 is connected to the sodium hydroxide box 5.

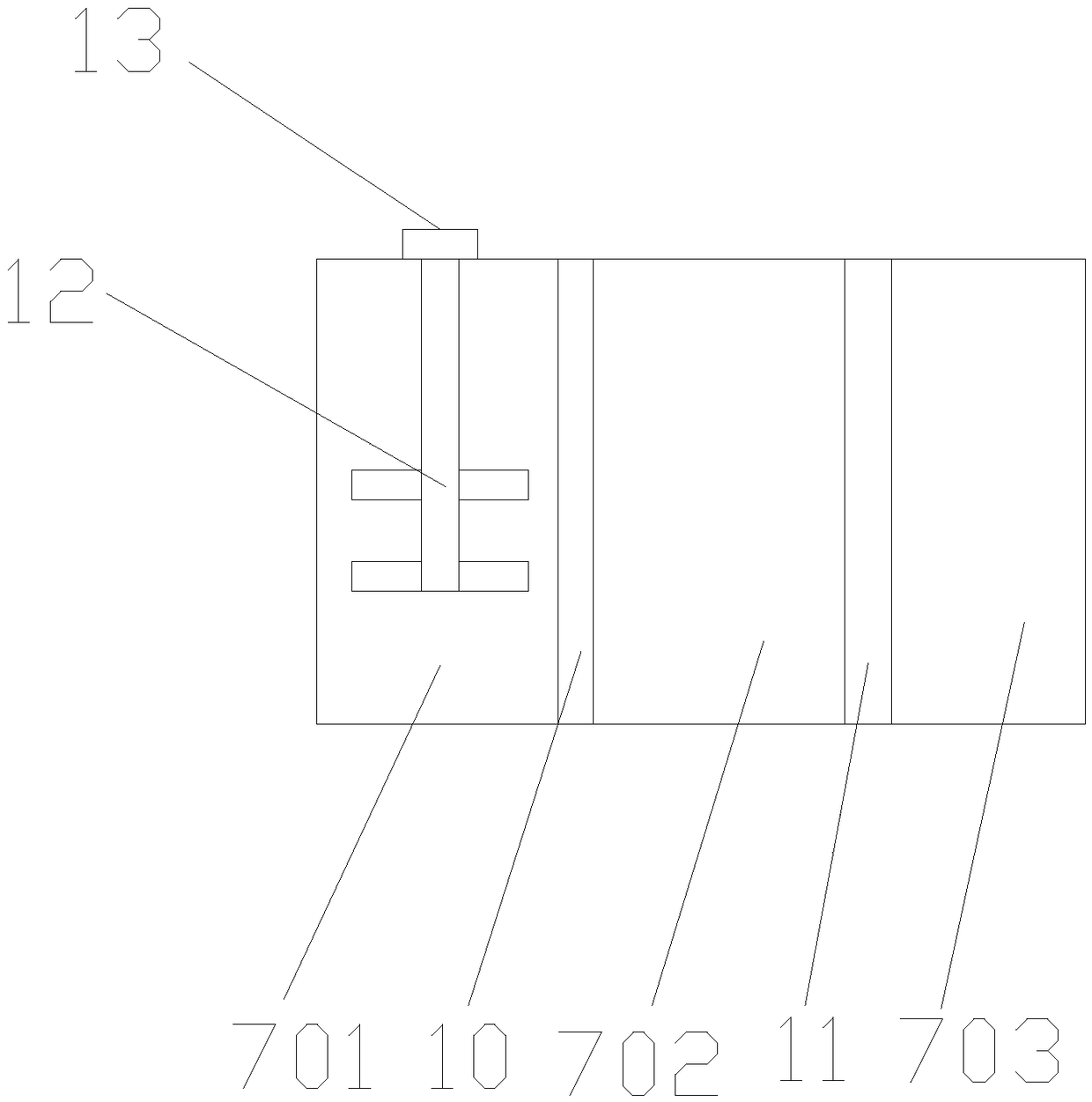

[0022] In this embodiment, the reaction tank 7 is divided into a reaction zone 701, a precipitation zone 702, and a circulation zone 703. In the reaction zone 701, the calcium sulfate produced by the reaction of sodium hydroxide solution and sulfur dioxide ...

Embodiment 2

[0028] A dual-alkali desulfurization and dedusting recycling method, the steps are as follows: Step 1, flue gas dedusting, after the flue gas is discharged, it is dedusted through a dust removal box, and the dedusted flue gas enters a desulfurization tower for desulfurization; Step 2, wet desulfurization Desulfurization, through wet alkaline desulfurization, use sodium hydroxide solution to spray the solution on the top of the desulfurization tower to react with the sulfide in the flue gas in the desulfurization tower, and the sulfuric acid solution produced by the reaction falls to the bottom of the desulfurization tower; Step 3, treatment and recovery, desulfurization The sulfuric acid solution produced at the bottom of the tower leads the sulfuric acid solution into the reaction tank through the conduit, and adds calcium hydroxide solution into the reaction tank to make the calcium hydroxide react with the sulfuric acid solution to produce insoluble calcium sulfate. In the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com