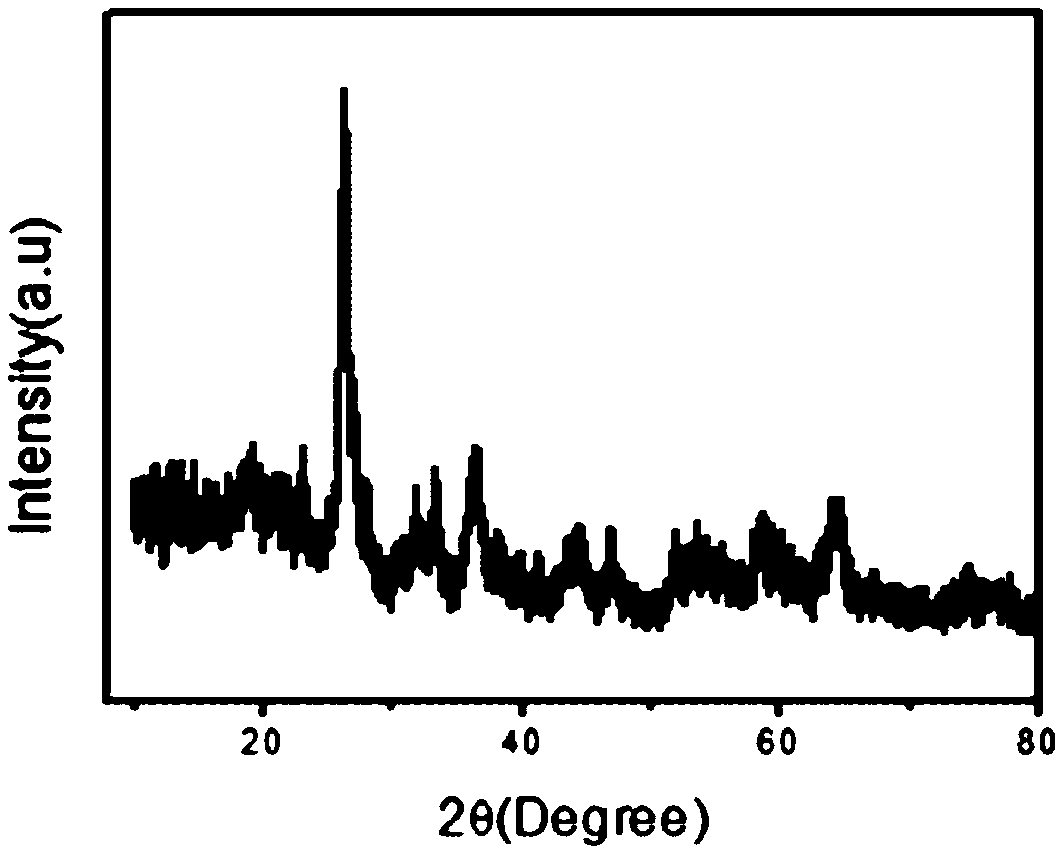

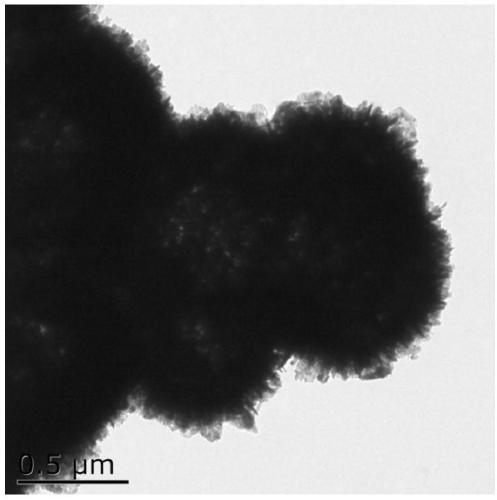

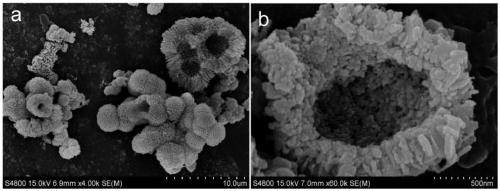

Preparation method of cobalt molybdate hollow microsphere electrocatalyst

A technology of hollow microspheres and electrocatalysts, applied in chemical instruments and methods, physical/chemical process catalysts, cobalt compounds, etc., can solve the problems of scarce resources and high prices of noble metal oxygen evolution electrocatalysts, achieve efficiency and reduce use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the first step, weigh 1mmol (290mg) of cobalt nitrate, 1mmol (240mg) of sodium molybdate, and 4mmol (820mg) of anhydrous sodium acetate, each of which is fully dissolved in 10ml of deionized water. First, the sodium molybdate aqueous solution is slowly added to the cobalt nitrate In the aqueous solution, and assisted by magnetic stirring, the aqueous solution of sodium acetate is slowly added to the above-mentioned mixed solution of sodium molybdate and cobalt nitrate, and the mixed solution of these three reactants is magnetically stirred at room temperature for 0.5h, and finally The reactant solution was transferred to a 50ml polytetrafluoroethylene reactor. The volume of the reactant solution was 60% of the volume of the reactor. O C sealed heating for 20h, after the reactor is naturally cooled to room temperature, the solid precipitate in the reactor is taken out, and cleaned with deionized water and alcohol, and then the cleaned sample is heated at 60 O After dryi...

Embodiment 2

[0024] In the first step, weigh 1mmol (290mg) of cobalt nitrate, 1mmol (240mg) of sodium molybdate, and 4mmol (820mg) of anhydrous sodium acetate, each of which is fully dissolved in 10ml of deionized water. First, the sodium molybdate aqueous solution is slowly added to the cobalt nitrate In the aqueous solution, and assisted by magnetic stirring, the aqueous solution of sodium acetate is slowly added to the above-mentioned mixed solution of sodium molybdate and cobalt nitrate, and the mixed solution of these three reactants is magnetically stirred at room temperature for 0.5h, and finally The reactant solution was transferred to a 50ml polytetrafluoroethylene reactor. The volume of the reactant solution was 60% of the volume of the reactor. O C sealed heating for 20h, after the reactor is naturally cooled to room temperature, the solid precipitate in the reactor is taken out, and cleaned with deionized water and alcohol, and then the cleaned sample is heated at 60 O After dryi...

Embodiment 3

[0027] In the first step, weigh 1mmol (290mg) of cobalt nitrate, 1mmol (240mg) of sodium molybdate, and 4mmol (820mg) of anhydrous sodium acetate, each of which is fully dissolved in 10ml of deionized water. First, the sodium molybdate aqueous solution is slowly added to the cobalt nitrate In the aqueous solution, and assisted by magnetic stirring, the aqueous solution of sodium acetate is slowly added to the above-mentioned mixed solution of sodium molybdate and cobalt nitrate, and the mixed solution of these three reactants is magnetically stirred at room temperature for 0.5h, and finally The reactant solution was transferred to a 50ml polytetrafluoroethylene reactor. The volume of the reactant solution was 60% of the volume of the reactor. O C sealed heating for 20h, after the reactor is naturally cooled to room temperature, the solid precipitate in the reactor is taken out, and cleaned with deionized water and alcohol, and then the cleaned sample is heated at 60 O After dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com