Cleaning method for quartz glass swing pieces

A technology of quartz glass and cleaning baskets, applied in the directions of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc. Surface cleanliness, damage avoidance, high number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

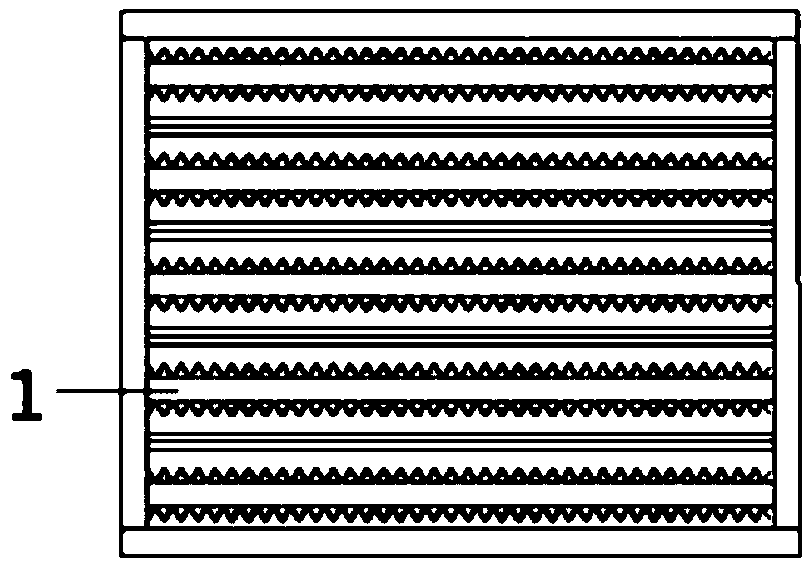

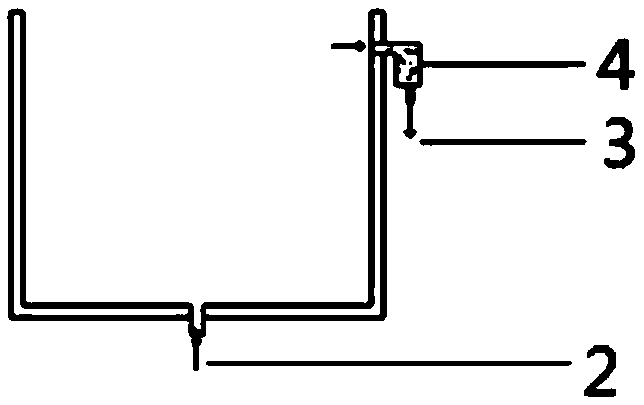

[0040] An embodiment of the present invention proposes a cleaning device for a quartz glass plate, which mainly includes four parts: pickling station, pure water rinsing station, pure water ultrasonic cleaning station, and slow drying station. The pickling station uses a sealable container made of PVC material that is resistant to hydrofluoric acid corrosion, and contains a hydrofluoric acid solution with a mass fraction of 0.5-3% inside; the pure water rinsing station uses a container made of PVC material that is resistant to hydrofluoric acid corrosion. Equipped with automatic water inlet and overflow switches; the pure water ultrasonic cleaning station includes at least three levels of cleaning, using a stainless steel sink, with multiple ultrasonic generators evenly distributed at the bottom, the vibration frequency of the ultrasonic generator in the first cleaning tank is 45KHz, and the second The vibration frequency of the ultrasonic generator in the first-level cleaning ...

Embodiment 2

[0046] One embodiment of the present invention proposes a cleaning method for a quartz glass pendulum, which includes: placing the quartz glass pendulum in a cleaning basket, followed by pickling, rinsing, ultrasonic cleaning and slow drying.

[0047] The pickling step is as follows: place the quartz glass pendulum in a cleaning basket, put it into 0.5-3% hydrofluoric acid solution, the temperature is 25°C, and the pickling time is 2-5 minutes. The following chemical reactions take place in the acid solution to etch away the glass surface and any stubborn adherents on it. The cleaning basket is made of acid-resistant plastic, and the pendulum plate is only placed in three-point contact, and multiple pendulum plates can be placed at the same time, and the distance between the plates is not less than 5mm.

[0048] The pure water rinsing step is as follows: the residual acid solution on the surface of the quartz glass pendulum taken out from the acid solution is rinsed with deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com