Preparation method of device based on two-dimensional material

A technology for two-dimensional materials and devices, applied in the field of two-dimensional materials, can solve problems such as restricting the practical process of two-dimensional material devices, reducing the performance of two-dimensional material devices, and contamination of two-dimensional materials, so as to avoid electron beam lithography equipment or Micro transfer system, simple and efficient preparation, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, a kind of preparation method of the device based on multilayer molybdenum disulfide, comprises the steps:

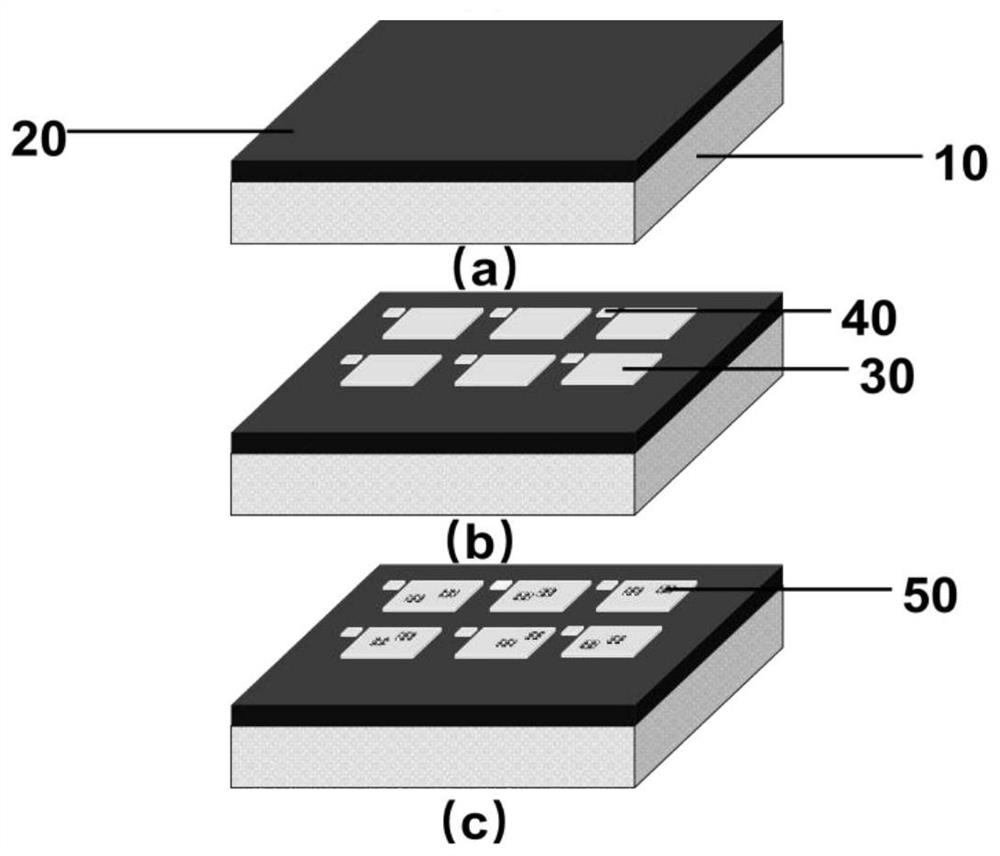

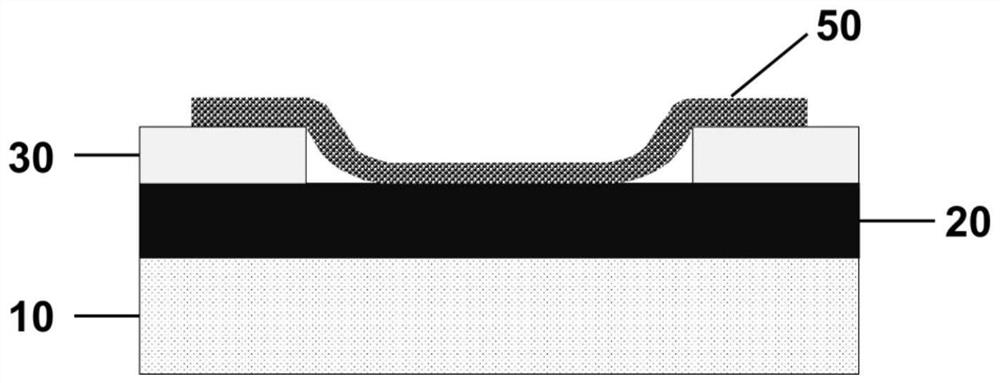

[0027] Step 1: Clean the silicon-based substrate with an oxide layer ultrasonically for 5-10 minutes with acetone and isopropanol, then rinse with deionized water and blow dry with nitrogen. like figure 2 As shown in (a), 10 is a silicon-based substrate, and 20 is an oxide layer. In other embodiments, the target substrate can also be a substrate material or a flexible substrate used in other semiconductor processes;

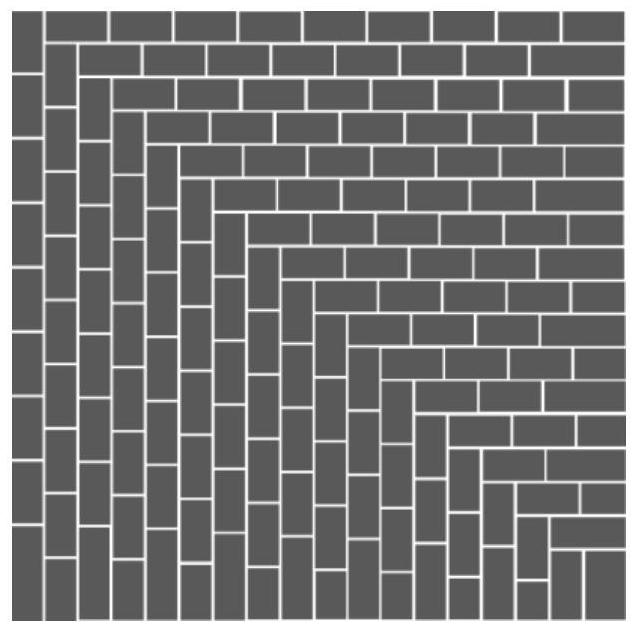

[0028] Step 2: On the surface of the silicon-based substrate with the oxide layer grown in step 1, use a positive photolithography process to level the glue, use a marking plate containing a labyrinth source-drain electrode pattern to photolithography and pattern development;

[0029] Step 3: Place the developed target substrate in step 2 in the electron beam evaporation system, control the process conditions related to the electron ...

Embodiment 2

[0031] Embodiment 2, a kind of preparation method based on the device of single-layer or few-layer molybdenum disulfide, comprises the steps:

[0032] Step 1-2 is with embodiment 1;

[0033] Step 3: Place the developed target substrate in step 2 in a plasma etching system, control the process parameters of the plasma etching process, and determine the corresponding etching depth according to the thickness of the source and drain electrodes to be grown. Because of the existence of the photoresist, during the etching process, the marks and the source and drain electrodes of the target substrate are etched, while the regions other than the marks and the source and drain electrodes remain intact. The power of plasma etching can be controlled at 300-600 W, and the plasma etching time can be controlled at 10-120 s;

[0034] Step 4: Place the etched target substrate in step 3 in the electron beam evaporation system, control the process conditions related to the electron beam evapora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| etching power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com