Continuous casting production technology for producing wide and thick-cross section pipeline steel casting blank

A production process and pipeline steel technology, applied in the field of metallurgy, can solve the problems of uneven distribution of mold slag and liquid slag, low acceptance rate of inclusion rating, and low pass rate of steel plate flaw detection, so as to reduce the occurrence of slag entrainment and improve contract fulfillment. The effect of improving the pass rate of flaw detection and the pass rate of inclusion rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A continuous casting production process for producing wide and thick section pipeline steel slabs provided in this embodiment includes the following specific steps:

[0036] (1) Online baking

[0037] The upper nozzle of the tundish is embedded in the bottom of the tundish, and the lower nozzle of the tundish is installed under the tundish. Before the casting machine starts casting, the tundish and the lower nozzle of the tundish are baked online for 150 minutes. The internal temperature of the tundish measured by the continuous temperature measurement system (model BCT-V) is 1200°C, and the temperature of the outer wall of the nozzle of the tundish is detected by a contact thermometer to be 1100°C, which meets the pouring conditions, of which:

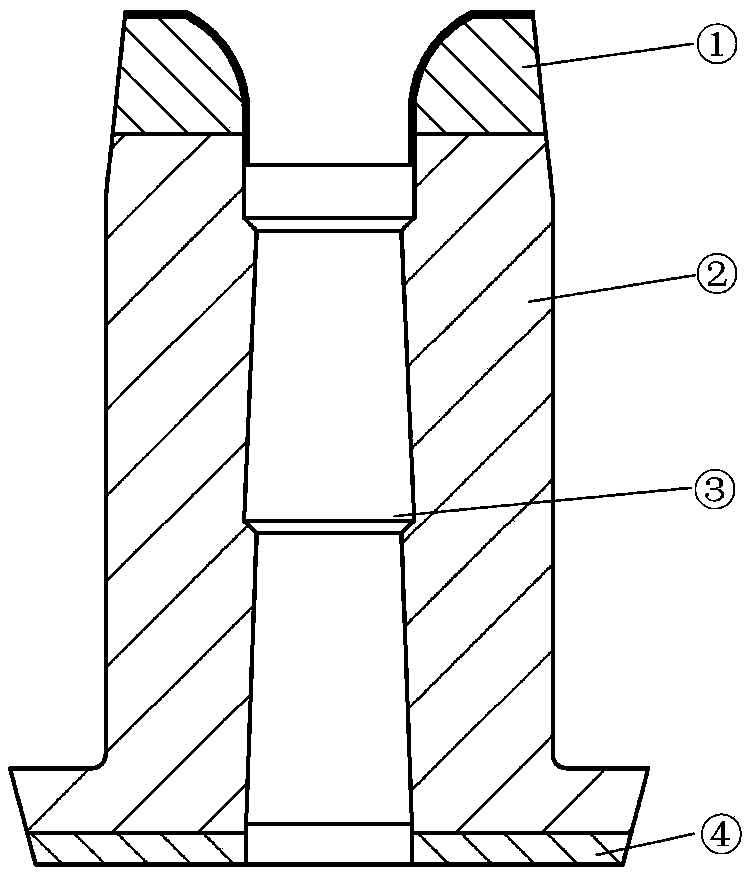

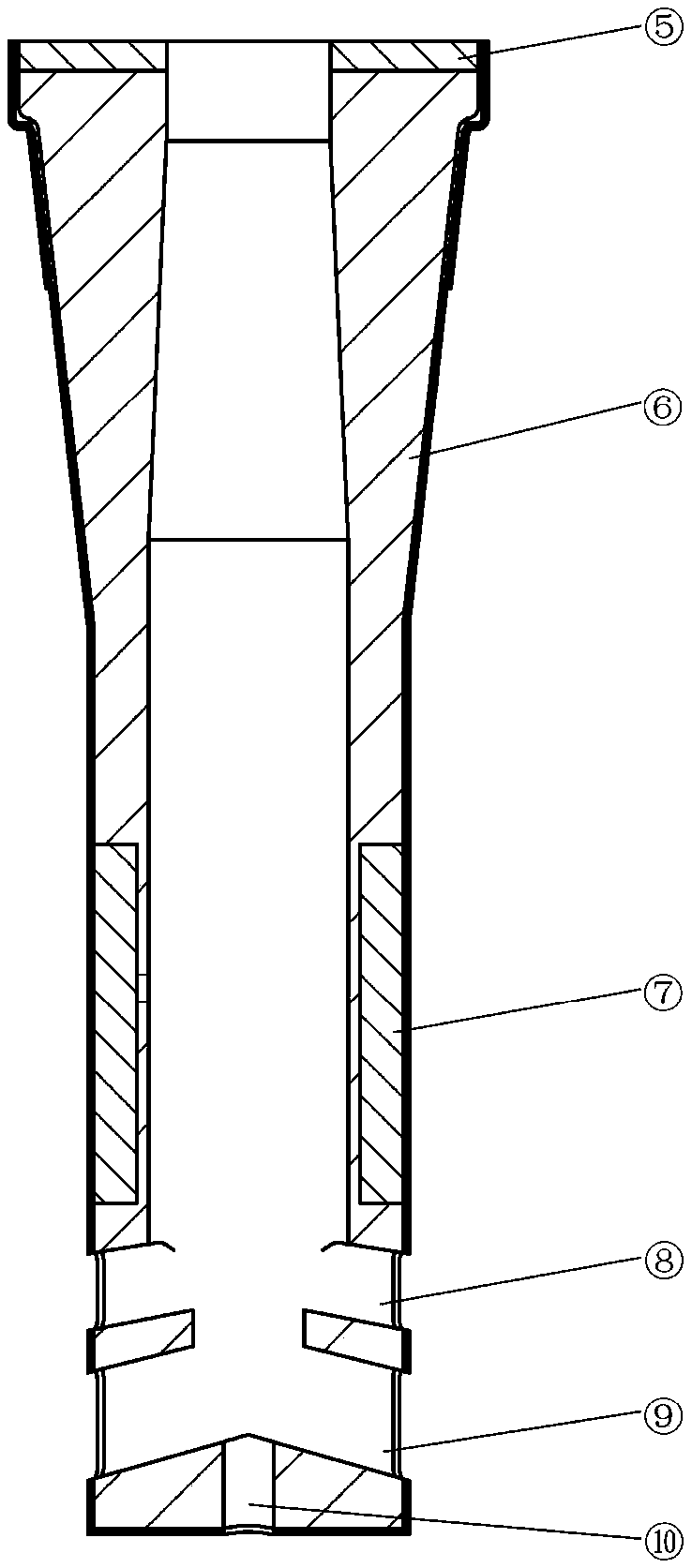

[0038] The upper nozzle of the tundish includes the upper nozzle upper fitting 1, the upper nozzle body 2, the upper nozzle passing through the steel channel 3 and the upper nozzle plate fitting 4, the upper nozzle body 2 is a ...

Embodiment 2

[0051] A continuous casting production process for producing wide and thick section pipeline steel slabs provided in this embodiment includes the following specific steps:

[0052] (1) Online baking

[0053] The upper nozzle of the tundish is embedded in the bottom of the tundish, and the porous tundish lower nozzle is installed under the tundish. Before the casting machine starts casting, the tundish and the porous lower nozzle are baked online for 180 minutes. The continuous temperature measurement system (model BCT-V) measures the internal temperature of the tundish as 1220°C, and the temperature of the outer wall of the nozzle of the tundish is detected by a contact thermometer as 1150°C, which meets the pouring conditions, of which:

[0054] The upper nozzle of the tundish includes the upper nozzle upper fitting 1, the upper nozzle body 2, the upper nozzle passing through the steel channel 3 and the upper nozzle plate fitting 4, the upper nozzle body 2 is a hollow structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com