Method for simply controlling arrangement direction of laser-induced surface periodic structure

A periodic structure and laser-induced technology, applied in the field of laser applications, can solve problems such as high cost, complicated operation, and complicated process, and achieve the effects of simple control, improved processing efficiency, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

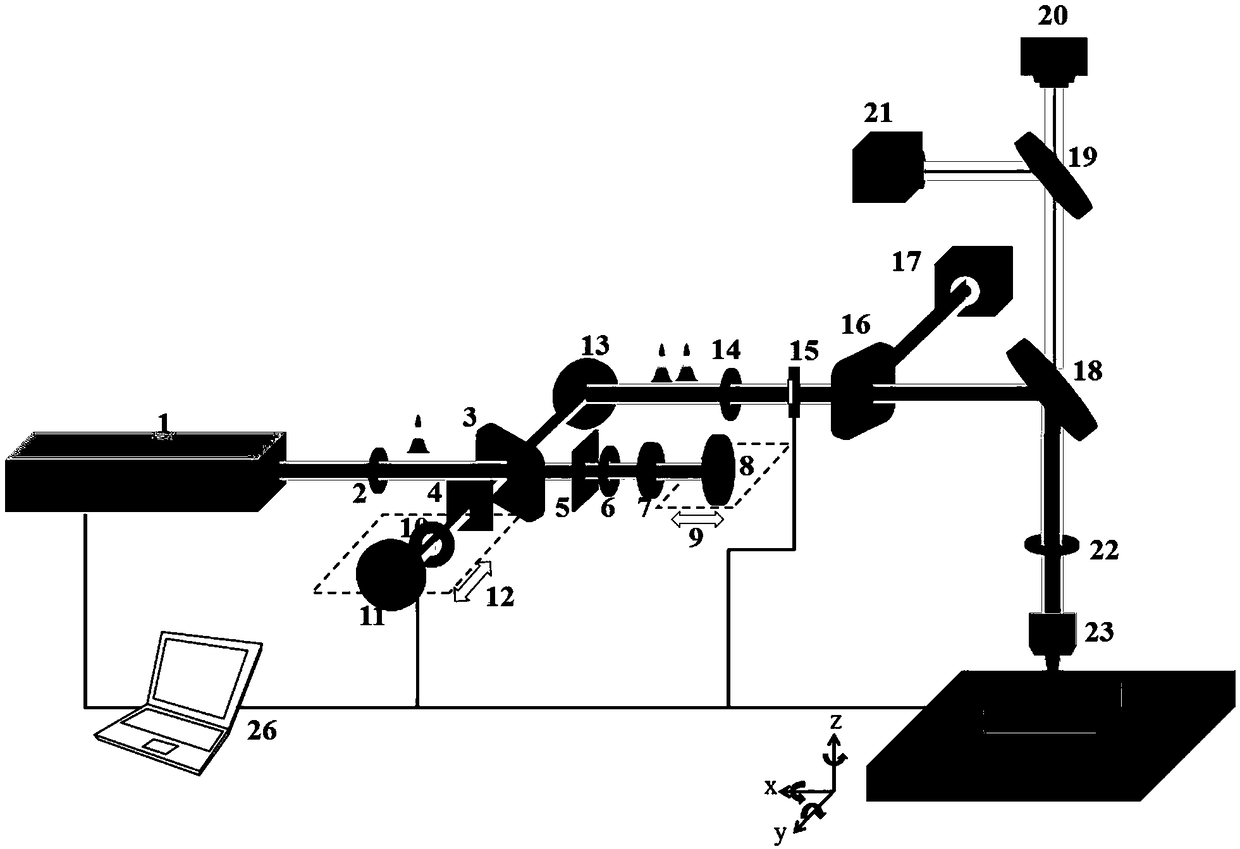

[0027] Taking the method of the present invention to process a periodic structure with a linear path perpendicular to the scanning direction on the surface of the Si material as an example, use such as figure 1 The light path structure shown, the specific equipment used is as follows:

[0028] The femtosecond laser 1 used in this embodiment is a laser produced by Spectrum Physics, with a laser center wavelength of 800 nm, a pulse width of 50 fs, a maximum repetition frequency of 1 KHz, a single pulse maximum energy of 3 mJ, and a Gaussian light intensity distribution. The exit laser is horizontally polarized.

[0029] The structure of the Michelson interferometer consists of the following parts: a first beam splitter 3, a first mirror 8, a second mirror 11, a manual mechanical translation stage 9, and an electromechanical translation stage 12. The manual mechanical translation stage 9 is adjusted to make the two sub-pulses zero delay, and the electromechanical translation stage 12 ...

Embodiment 2

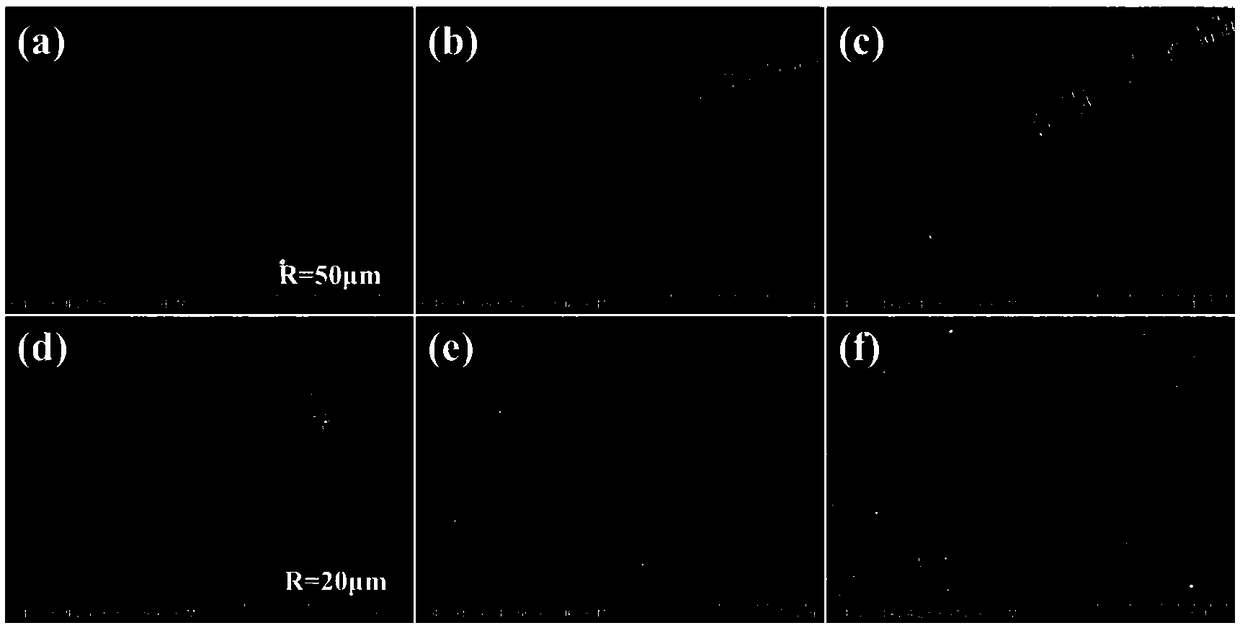

[0040] The other steps are the same as in embodiment 1, the difference is: in step (4), the scanning path is no longer a straight line, but a circular path with a radius of 50μm and 20μm. The structure arrangement direction is perpendicular to the scanning direction. Periodic structure, such as image 3 Shown.

Embodiment 3

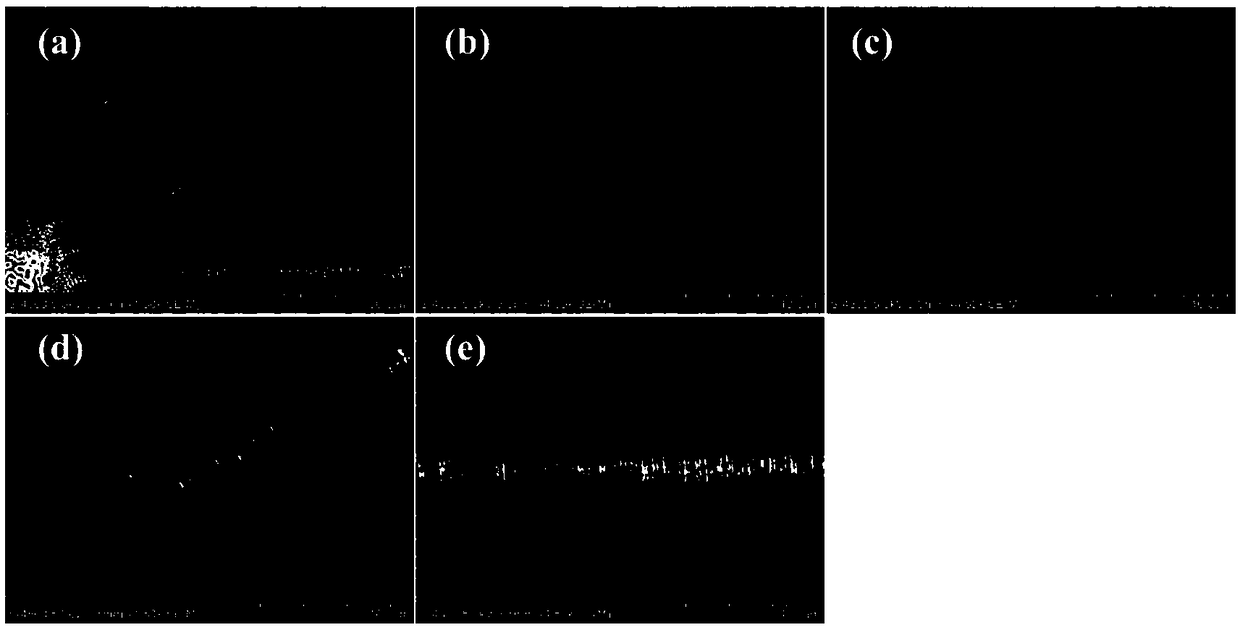

[0042] The other steps are the same as in embodiment 1, the difference is: in step (4), the scanning path is no longer a straight line but a sinusoidal path, and the periodic structure of the sinusoidal path with the structure arrangement direction perpendicular to the scanning direction is obtained, such as Figure 4 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com