Environment-friendly soldering tin material and preparation process thereof

A technology of soldering material and preparation process, applied in the direction of welding/cutting medium/material, manufacturing tools, welding equipment, etc., can solve the problems of multiple impurities, user hazards, high ion pollution, etc., meet environmental protection requirements and improve welding effect , to avoid the effect of ion pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An environmentally friendly solder material, including tin, copper, nickel, lead, silver, bismuth, zinc, antimony, arsenic, iron, aluminum, cadmium and flux, the composition ratio of the above raw materials is 96% tin and 0.6% copper , nickel 0.07%, lead 0.05%, silver 0.05%, bismuth 0.05%, zinc 0.0005%, antimony 0.05%, arsenic 0.015%, iron 0.02%, aluminum 0.001%, cadmium 0.002%, and flux 3.1075%.

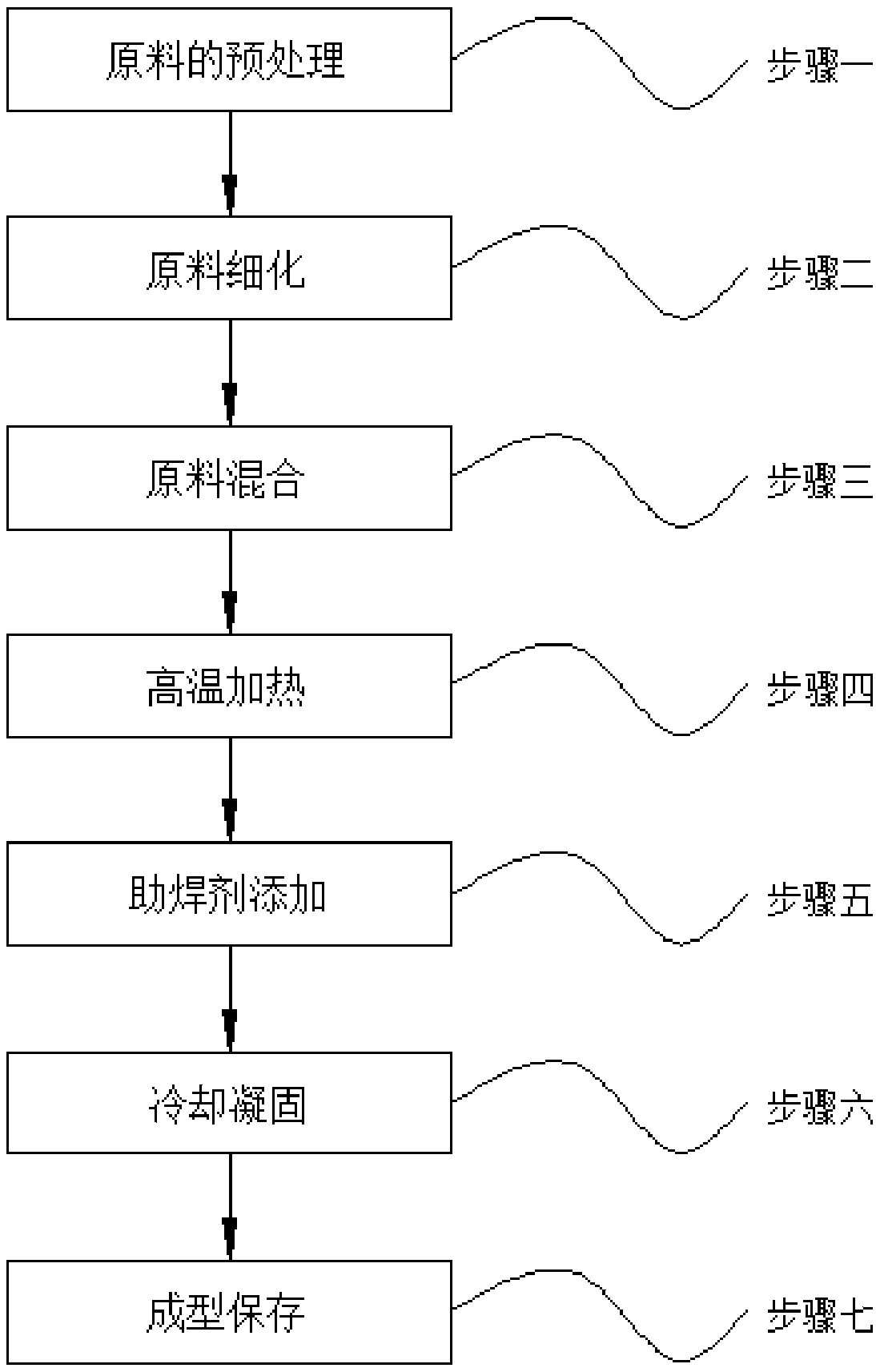

[0031] A preparation process of an environment-friendly solder material, comprising the following steps: Step 1, raw material pretreatment; Step 2, raw material refinement; Step 3, raw material mixing; Step 4, high temperature heating; Step 5, flux addition; Step 6 , cooling and solidification; step seven, molding and preservation;

[0032] Wherein in above-mentioned step one, select tin, copper, nickel, lead, silver, bismuth, zinc, antimony, arsenic, iron, aluminum, cadmium and flux as raw material, in the process of selecting raw material, tin, copper, Nickel, lead, silver...

Embodiment 2

[0041] An environmentally friendly solder material, including tin, copper, nickel, lead, silver, bismuth, zinc, antimony, arsenic, iron, aluminum, cadmium and flux, the composition ratio of the above raw materials is 96.5% tin, 0.552% copper , Nickel 0.07%, Lead 0.1%, Silver 0.06%, Bismuth 0.06%, Zinc 0.001%, Antimony 0.1%, Arsenic 0.015%, Iron 0.01%, Aluminum 0.001%, Cadmium 0.001%, and Flux 2.53%.

[0042] A preparation process of an environment-friendly solder material, comprising the following steps: Step 1, raw material pretreatment; Step 2, raw material refinement; Step 3, raw material mixing; Step 4, high temperature heating; Step 5, flux addition; Step 6 , cooling and solidification; step seven, molding and preservation;

[0043] Wherein in above-mentioned step one, select tin, copper, nickel, lead, silver, bismuth, zinc, antimony, arsenic, iron, aluminum, cadmium and flux as raw material, in the process of selecting raw material, tin, copper, Nickel, lead, silver, bi...

Embodiment 3

[0052] An environmentally friendly solder material, including tin, copper, nickel, lead, silver, bismuth, zinc, antimony, arsenic, iron, aluminum, cadmium and flux, the composition ratio of the above raw materials is 95.5% tin and 0.8% copper , nickel 0.08%, lead 0.1%, silver 0.1%, bismuth 0.1%, zinc 0.001%, antimony 0.1%, arsenic 0.03%, iron 0.01%, aluminum 0.001%, cadmium 0.001%, and flux 3.177%.

[0053] A preparation process of an environment-friendly solder material, comprising the following steps: Step 1, raw material pretreatment; Step 2, raw material refinement; Step 3, raw material mixing; Step 4, high temperature heating; Step 5, flux addition; Step 6 , cooling and solidification; step seven, molding and preservation;

[0054] Wherein in above-mentioned step one, select tin, copper, nickel, lead, silver, bismuth, zinc, antimony, arsenic, iron, aluminum, cadmium and flux as raw material, in the process of selecting raw material, tin, copper, Nickel, lead, silver, bis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com