Hybrid transmission and vehicle using the same

A hybrid and transmission technology, applied in the automotive field, can solve problems such as engine drag torque resistance, achieve the effect of reducing drag resistance and improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

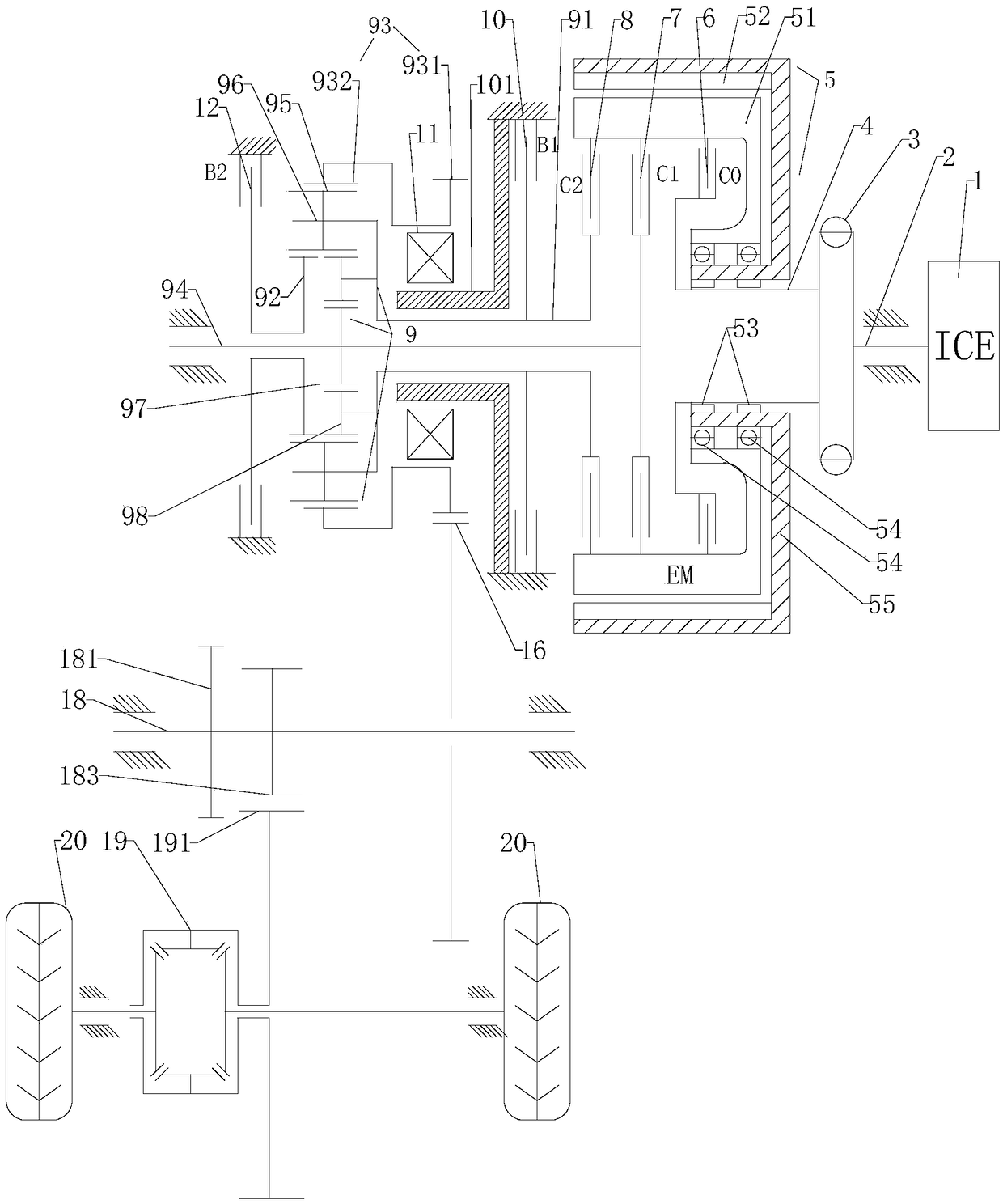

Embodiment 1

[0030] see figure 1 As shown, Embodiment 1 of the present invention provides a kind of hybrid power transmission comprising engine 1, motor 5, planetary gear mechanism 9 and output shaft 18; The first clutch 6 is arranged between the crankshaft 2 of engine and the rotor 51 of motor, uses It is used to connect or disconnect the crankshaft of the engine and the rotor of the motor, that is to say, the engagement or disconnection of the first clutch enables the connection or separation between the crankshaft of the engine and the rotor of the motor; the rotor of the motor and the planetary gear mechanism There is a second clutch 7 between them, which is used to engage or disconnect the rotor of the motor and the planetary gear mechanism, that is, to connect or separate the rotor of the motor and the planetary gear mechanism 9; the planetary gear mechanism 9 is used to connect The power input by the engine and / or motor is transmitted to the output shaft, that is, the engine transmi...

Embodiment 2

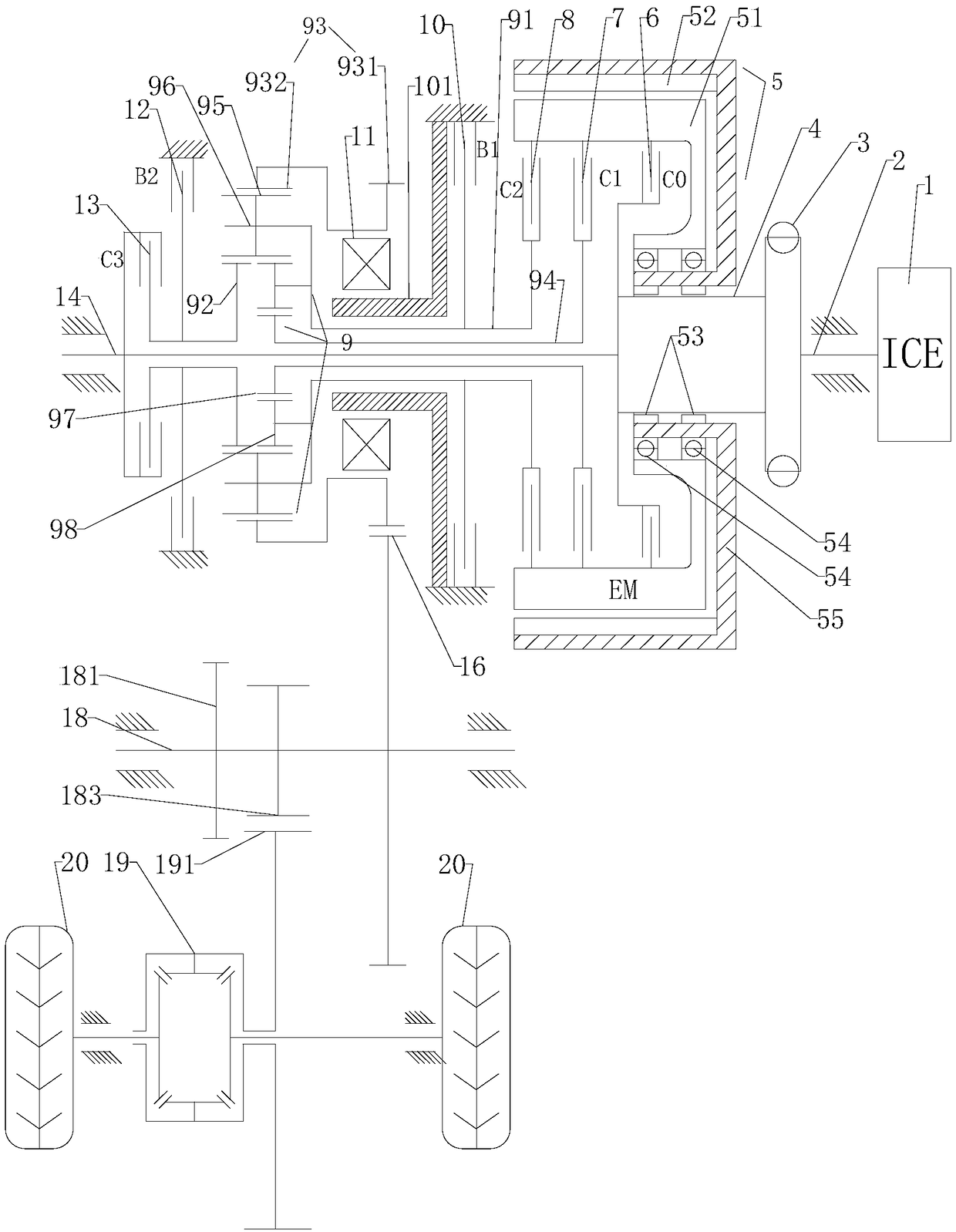

[0047] The hybrid transmission in the second embodiment is an improvement on the basis of the first embodiment. The technical content disclosed in the first embodiment will not be described repeatedly, and the content disclosed in the first embodiment also belongs to the content disclosed in the second embodiment.

[0048] see figure 2 As shown, in this embodiment, the hybrid transmission also includes a fourth clutch 13 and a reverse gear input shaft 14, the reverse gear input shaft is connected to the crankshaft of the engine, and the first transmission end of the fourth clutch is connected to the reverse gear of the planetary gear mechanism. The sun gear is connected, and the second transmission end of the fourth clutch is fixedly connected with the reverse gear input shaft, wherein the first transmission end of the fourth clutch can be engaged or disconnected from the second transmission end of the fourth clutch. Engagement of the fourth clutch enables the reverse gear in...

Embodiment 3

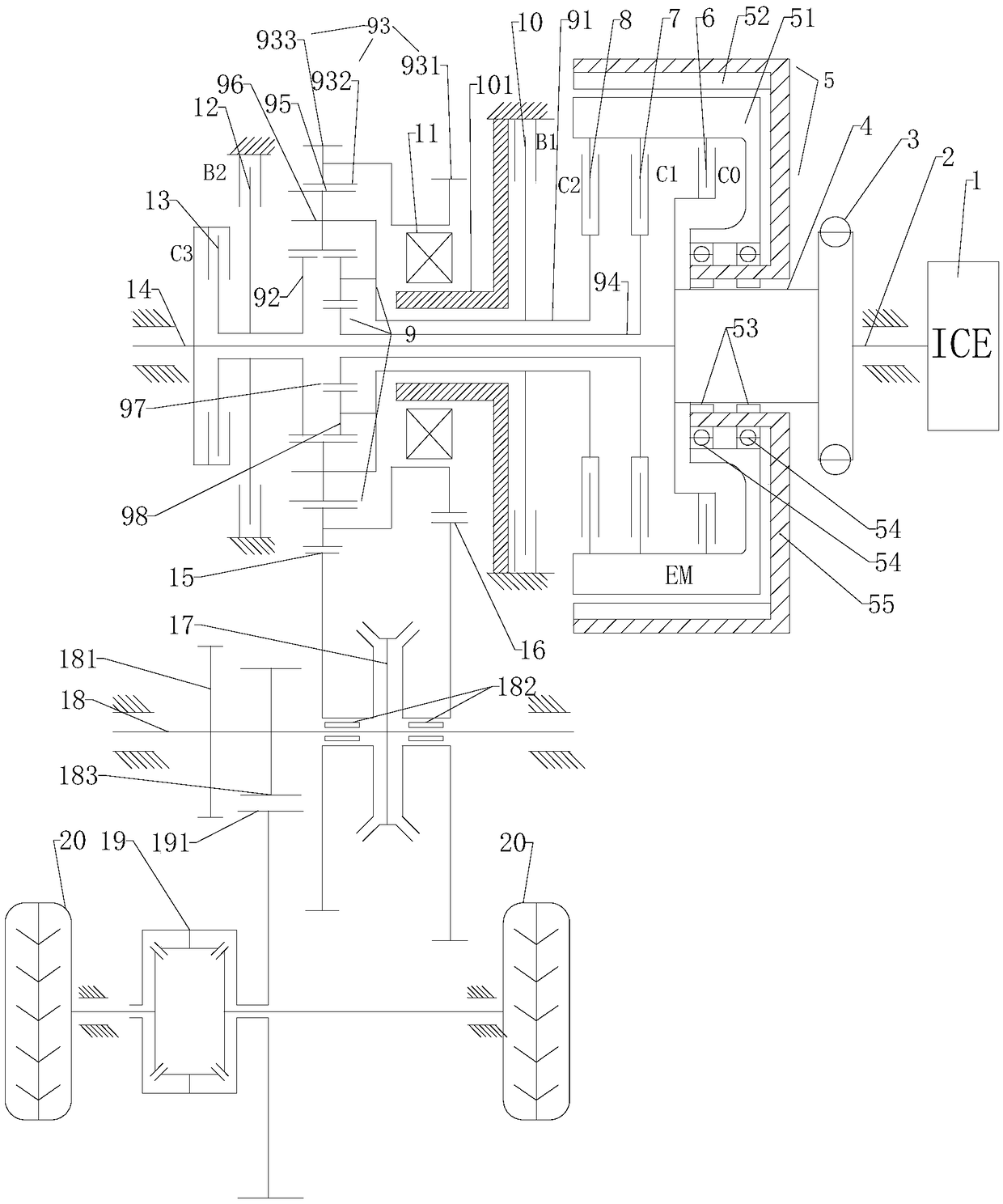

[0052] The hybrid transmission in the third embodiment is an improvement on the basis of the second embodiment. The technical content disclosed in the second embodiment will not be described repeatedly, and the content disclosed in the second embodiment also belongs to the content disclosed in the third embodiment.

[0053] see image 3 As shown, in this embodiment, the planetary gear ring gear further includes a large gear 933; the internal gear, the large gear and the pinion are fixed together and rotate coaxially. The diameter of the large gear is larger than the diameter of the small gear.

[0054] In an optional solution of this embodiment, a synchronizer 17 and a second gear 15 are also installed on the output shaft; the second gear may be a high-speed driven gear; the diameter of the second gear is smaller than that of the first gear. The synchronizer is located between the first gear and the second gear, and the first gear or the second gear drives the output shaft to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com