Denitrifying and dephosphorizing activated biocarrier, preparation method thereof and application thereof

A technology of nitrogen and phosphorus removal and biological carrier, applied in the direction of biological treatment devices, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of local pH being too low, the inability to achieve deep removal of soluble phosphate, and uneven distribution And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention also discloses a preparation method of a nitrogen and phosphorus removal active biological carrier, which comprises the following steps:

[0031] Pretreatment of sulfur and siderite;

[0032] Melting sulfur into a liquid state at 119-160°C, preferably 120-150°C, more preferably 130-140°C;

[0033] Maintain the above temperature, add siderite into the above liquid sulfur, stir and mix at a stirring speed of 400-700 rpm, preferably 410-600 rpm, more preferably 430-500 rpm, for 30-300 seconds, preferably 35-120 seconds, more preferably 40-70 rpm One second to get a mixture;

[0034] Put the above mixed solution into the cooling water at 4-80°C, preferably 20-70°C, more preferably 45-65°C through the mixed liquid distributor that controls the flow rate of the mixed liquid, and cool and shape for 0.5-10 minutes, preferably 1-7 minutes, more preferably 1 to 3 minutes, the mixed liquid outflow rate of the mixed liquid distributor is controlled at 0.75 to 3ml / ho...

Embodiment 1

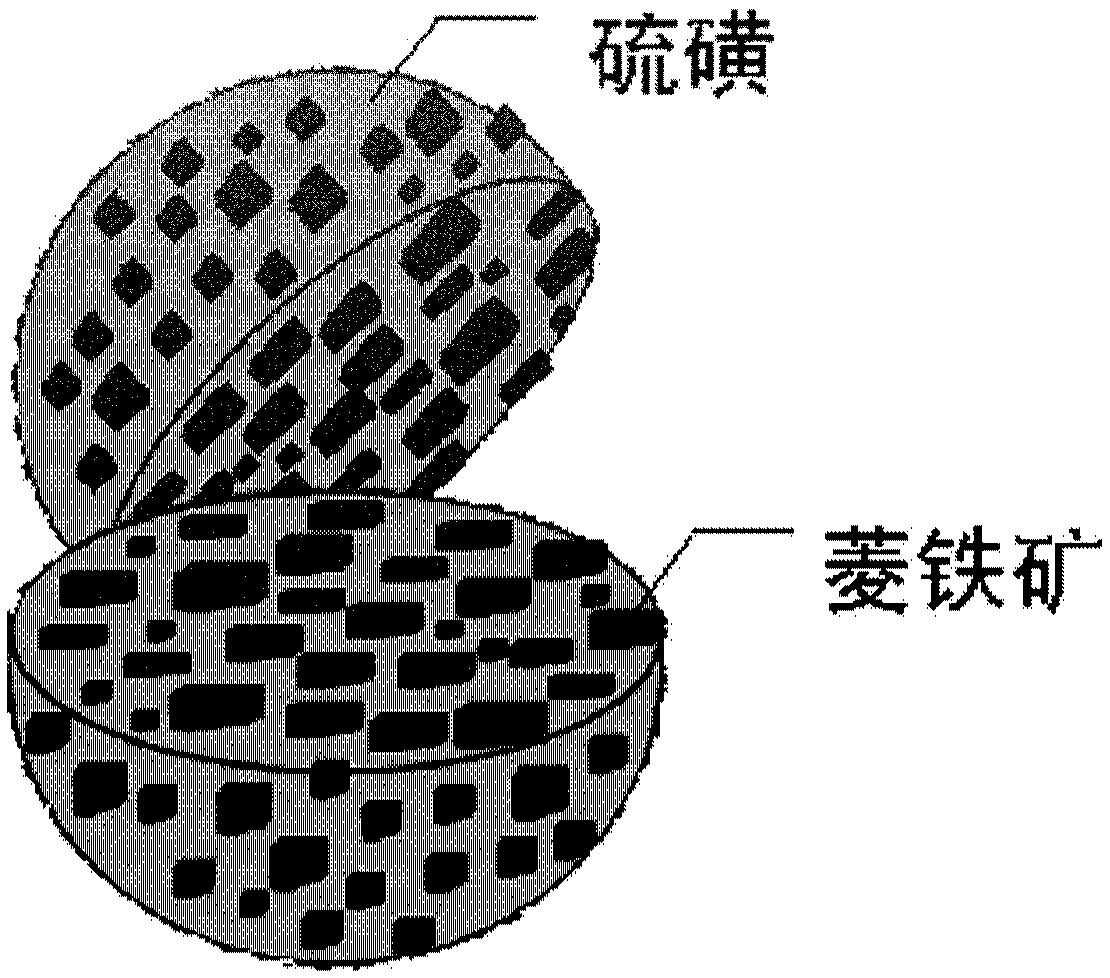

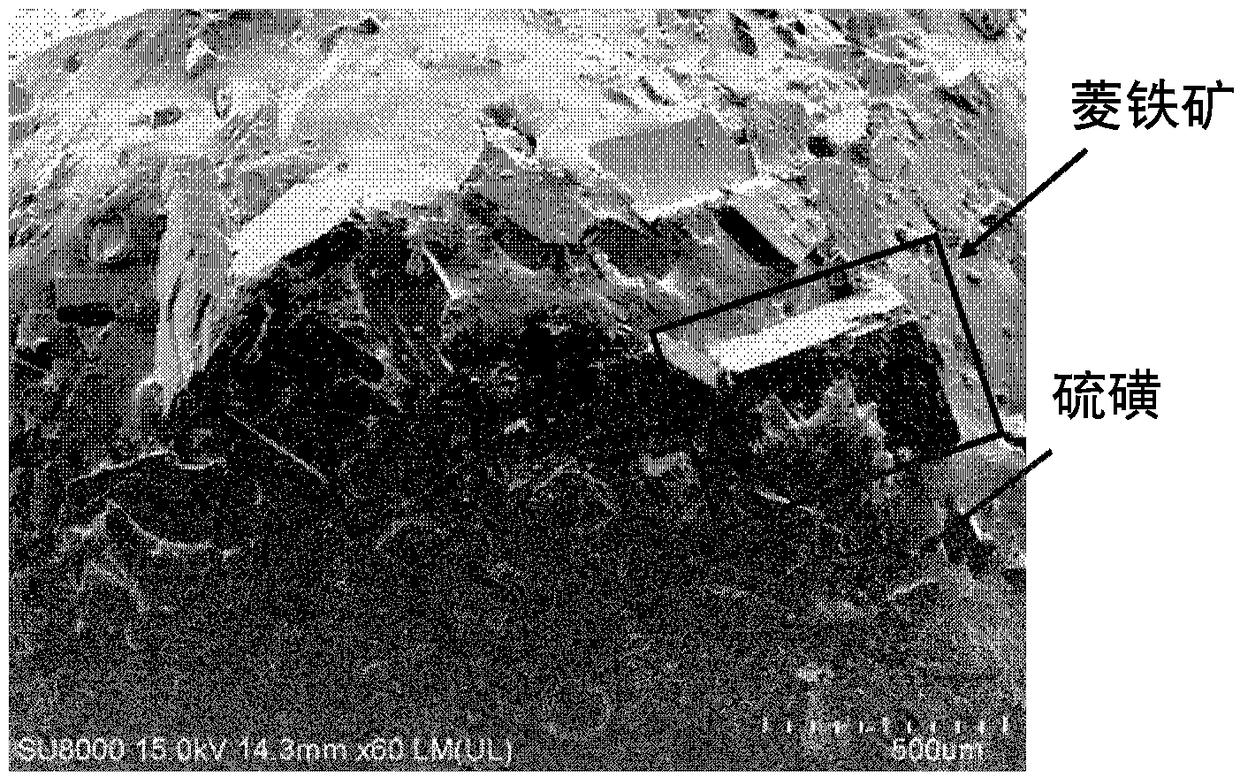

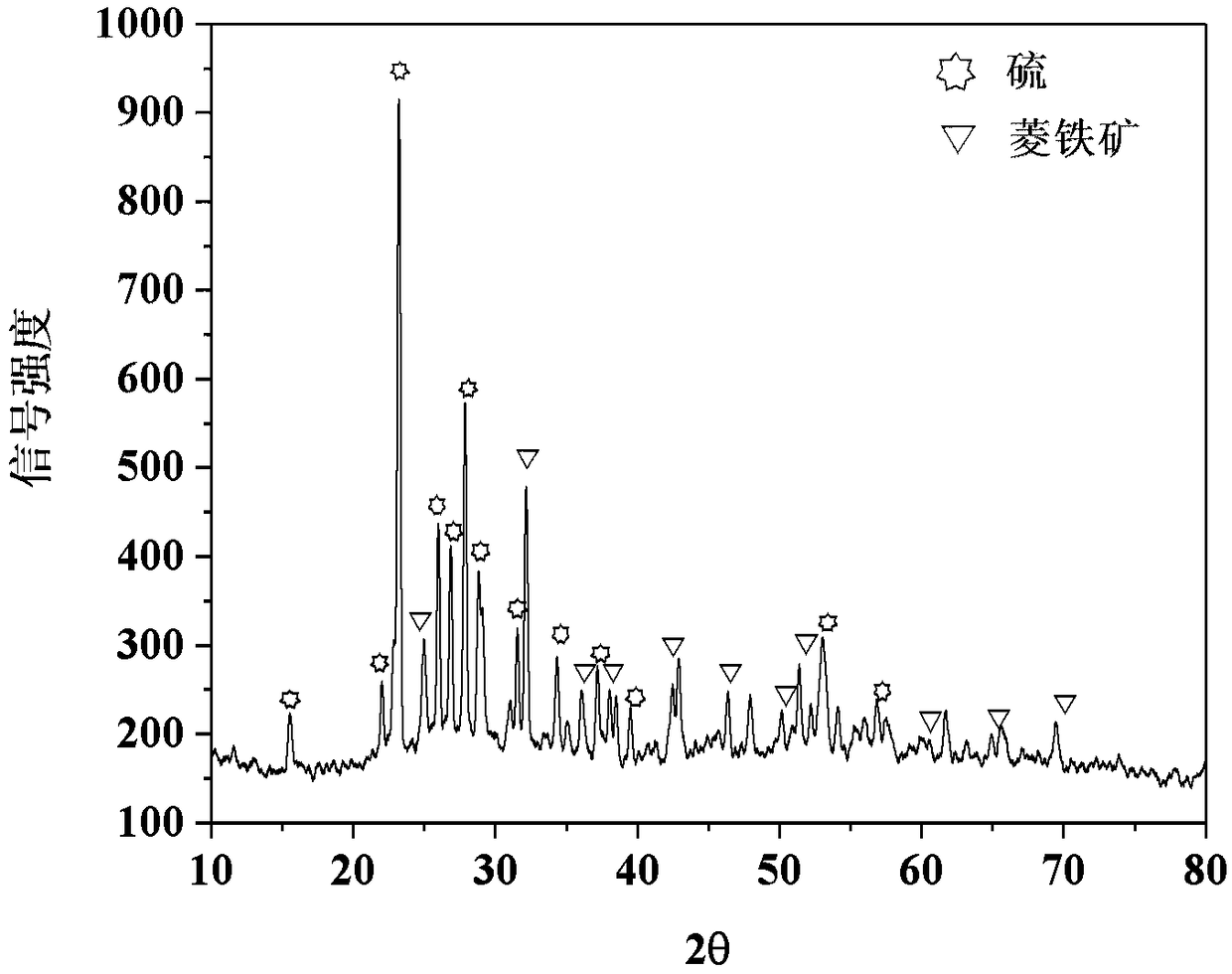

[0044] The nitrogen and phosphorus removal active biological carrier is prepared according to the composition of 50% sulfur and 50% siderite by mass ratio, and the specific preparation method is as follows:

[0045] 1. Add solid sulfur into the heating kettle, heat and melt it into liquid sulfur at 140°C, filter the liquid sulfur in stages to remove impurities with a particle size larger than 0.9 μm, and keep the temperature of the heating kettle at 140°C;

[0046] 2. Add the under-screened siderite sieved through a 60-mesh sieve to the liquid sulfur in the heating kettle in a ratio of 1:1 to the mass ratio of sulfur;

[0047] 3. Control the temperature in the heating kettle at 140°C, stir and mix the mixture of siderite and sulfur at a frequency of 450rpm for 2 minutes;

[0048] 4. The sulfur-siderite mixed solution is evenly and stably injected into the cooling water through the mixed solution distributor, and the flow rate is 3 ml per minute per hole;

[0049] 5. Cool the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com