Colored high performance concrete (RPC) prefabricated component and manufacturing method thereof

A technology of high-performance concrete and prefabricated components, applied in manufacturing tools, ceramic molding machines, etc., can solve problems such as depression, grayness, and monotonous appearance of ordinary concrete, and achieve high social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

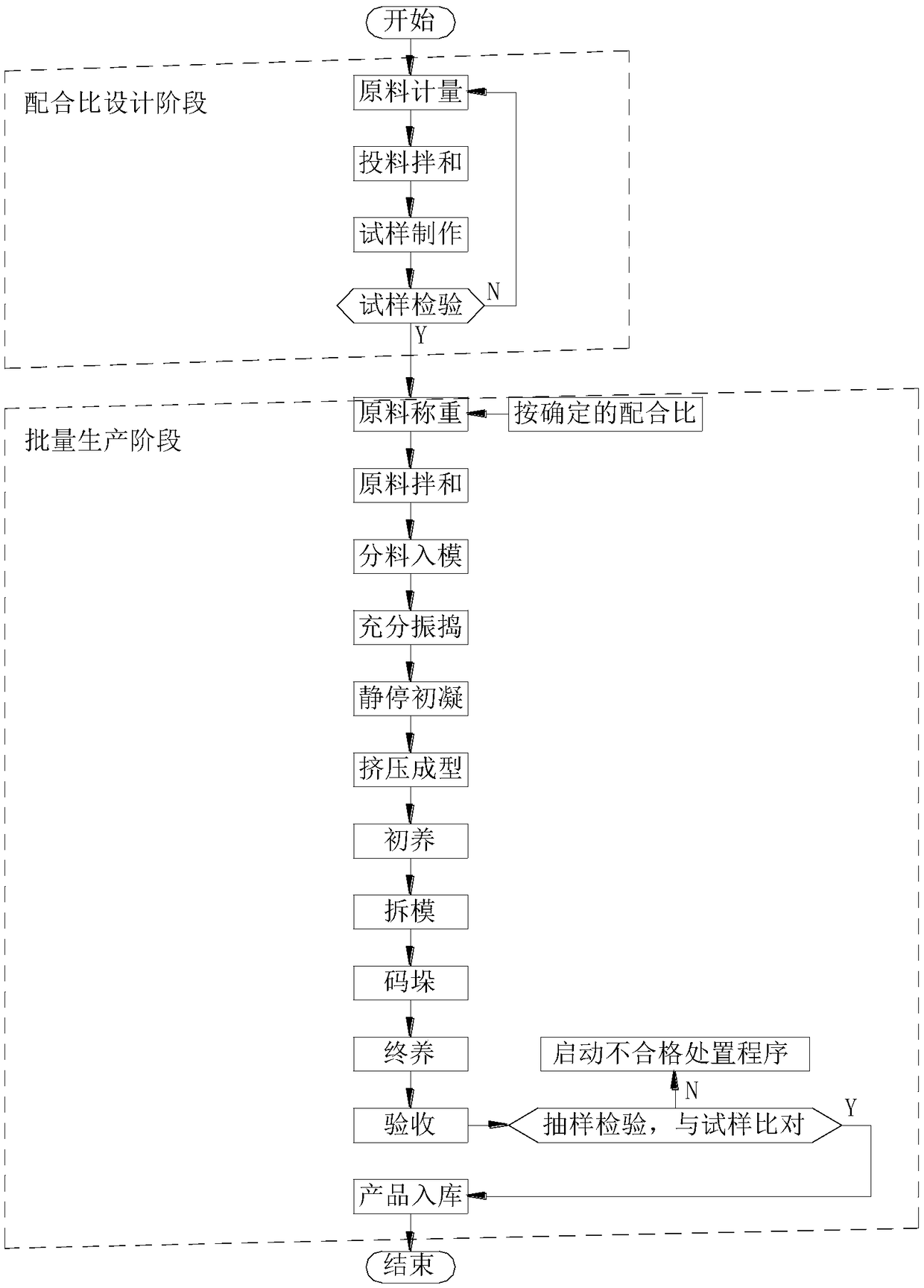

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereby.

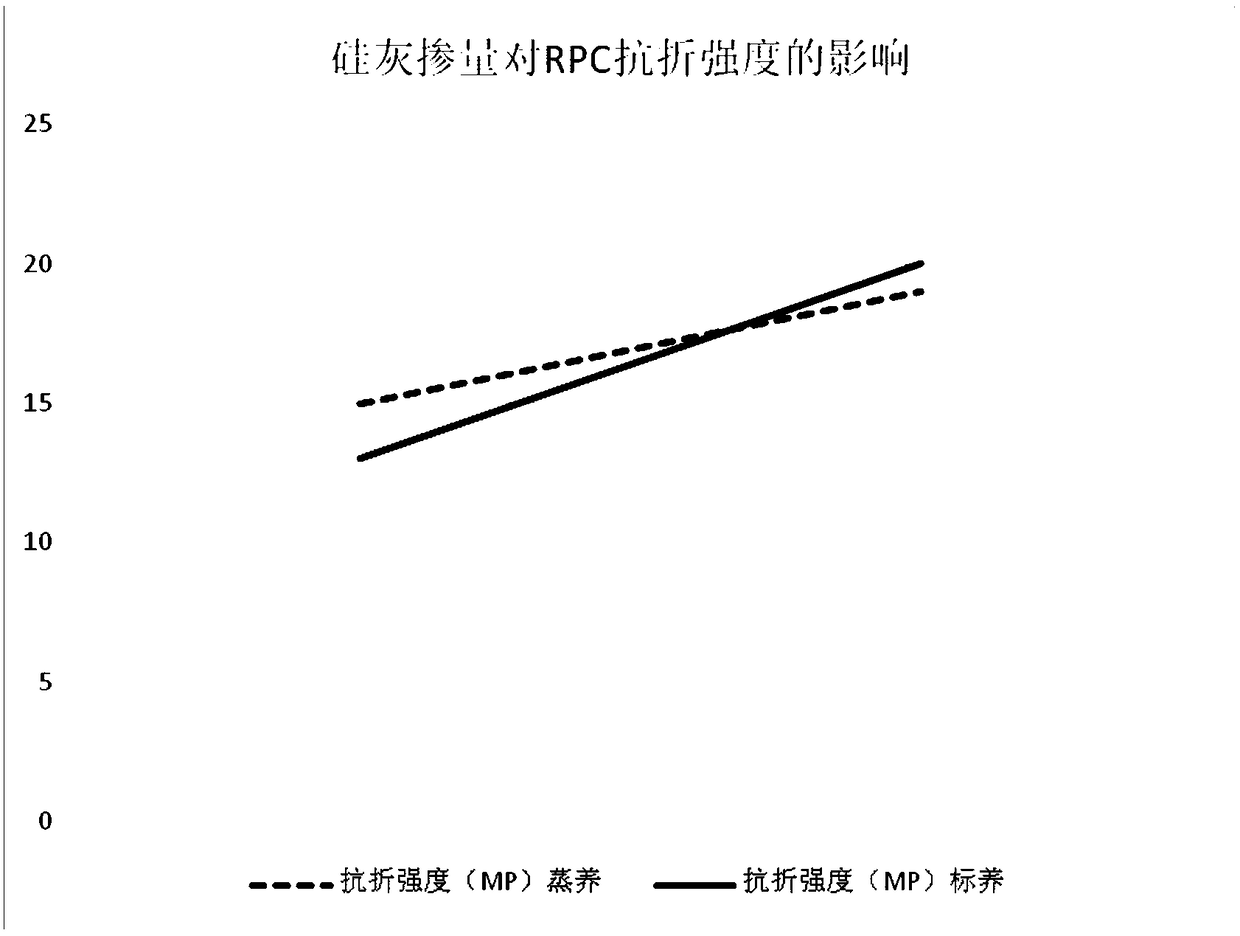

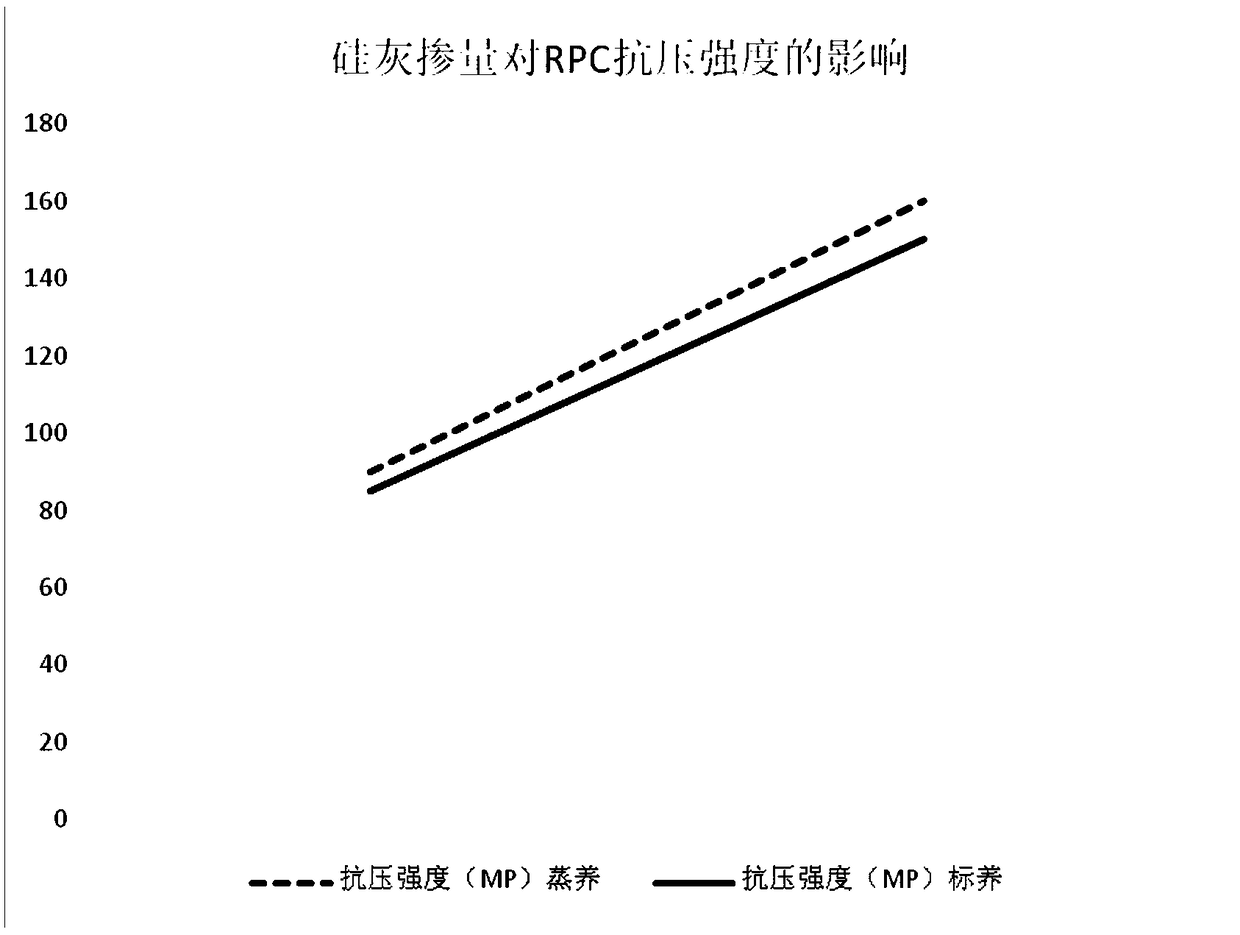

[0035] A colored high-performance concrete (RPC) prefabricated component according to the present invention is made of colored high-performance concrete (RPC), and the colored high-performance concrete (RPC) includes the following raw material components in parts by weight: cement 800-1200 , aggregate 1100-1300, silica fume 90-120, steel fiber 120-150, admixture 60-80, pigment 40-90, water 90-120.

[0036] The cement is preferably Jidong P.O42.5 cement.

[0037] The aggregate is preferably Haicheng quartz sand, which is sieved, the particle size is controlled between 0.16-1.25 mm, the mud content is less than 1.0%, and the color is uniform.

[0038] The admixture is preferably Shenyang Yilida polycarboxylate high-performance water reducer, with a water reducing rate of 30% and a solid content of 40%. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com