A method for smelting ti-if steel using vanadium-containing titanium molten iron

A technology of vanadium-titanium and molten iron, applied in the field of metallurgy, can solve the problems of long process flow and high energy consumption, and achieve the effects of reducing the energy consumption of the production process, improving the quality and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

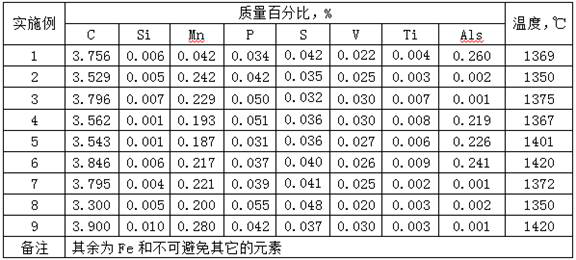

[0031] The invention provides a method for smelting Ti-IF steel by using vanadium-containing titanium molten iron, using vanadium-containing titanium molten iron to pre-dephosphorize, devanadium, and desiliconize through a vanadium-extracting converter, compound injection desulfurization, and decarburize and dephosphorize the steelmaking converter , RH refining process to obtain Ti-IF steel, the specific process is as follows:

[0032] (1) Pre-dephosphorization, vanadium removal, and desiliconization process: put the vanadium-titanium molten iron into the vanadium extraction converter, and perform pre-dephosphorization, vanadium removal, and desiliconization processes to obtain semi-steel I;

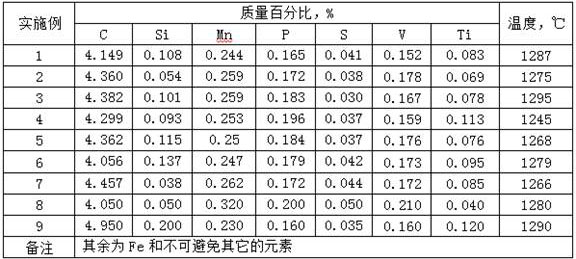

[0033] The vanadium-titanium-containing molten iron initial composition and temperature of this operation embodiment 1-9 are shown in Table 1;

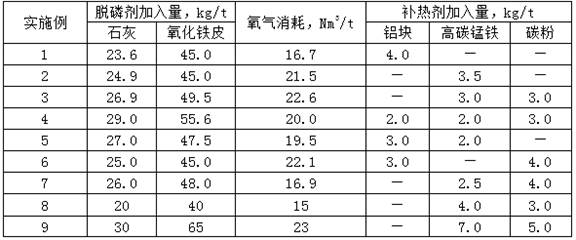

[0034] The loading amount of molten iron, the lime addition amount, the scale addition amount, the oxygen supply amount of this process embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com