9Ni steel plate residual magnetism control manufacturing method

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, heat treatment process control, process efficiency improvement, etc., can solve the problems of no clear report on the control of steel plate magnetism, achieve good magnetic properties, low magnetic properties, and ensure residual magnetism The effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

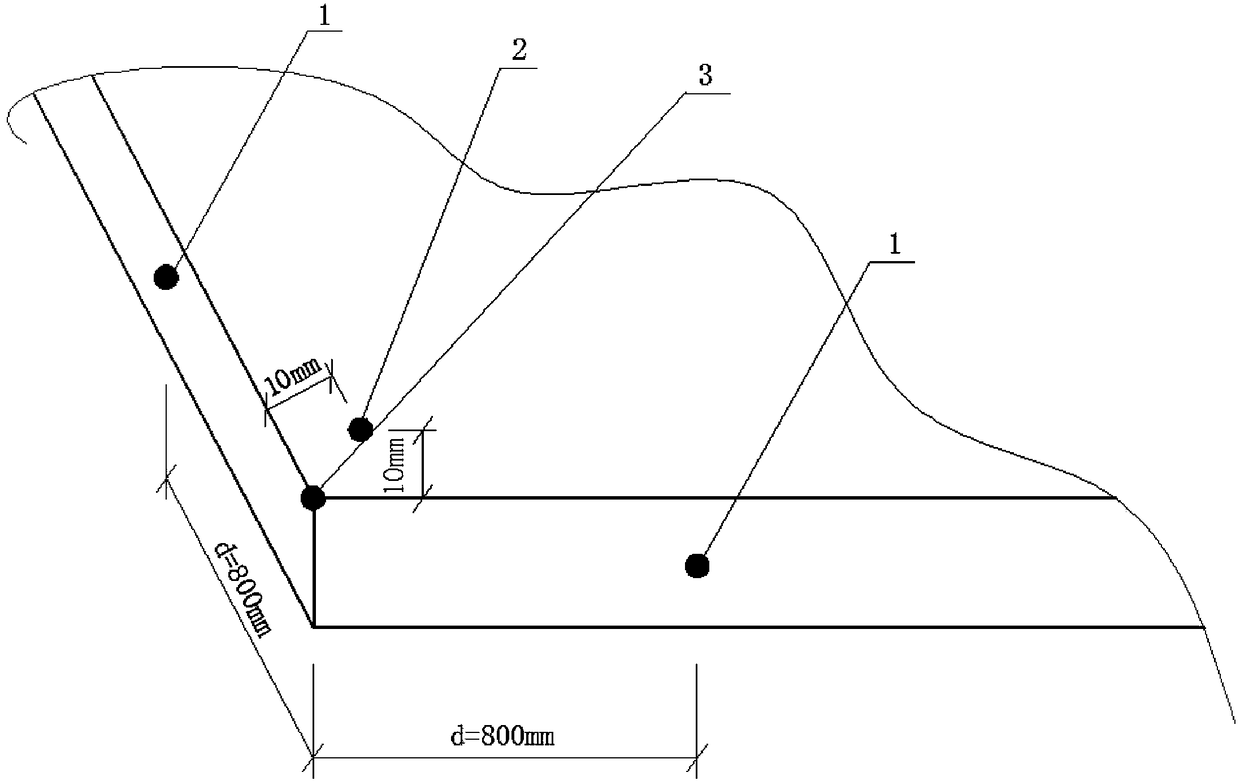

Image

Examples

Embodiment

[0036] Table 1: Steel plate specifications and heat treatment processes in Examples 1-3

[0037] Example

steel number

Specification mm

1

9Ni (06Ni9DR)

26.5×3030×11750

825-835℃

615-620℃

2

9Ni (06Ni9DR)

22.5×3030×11750

815-825℃

610-615℃

3

9Ni (06Ni9DR)

8×2000×7450

800-805℃

630-635℃

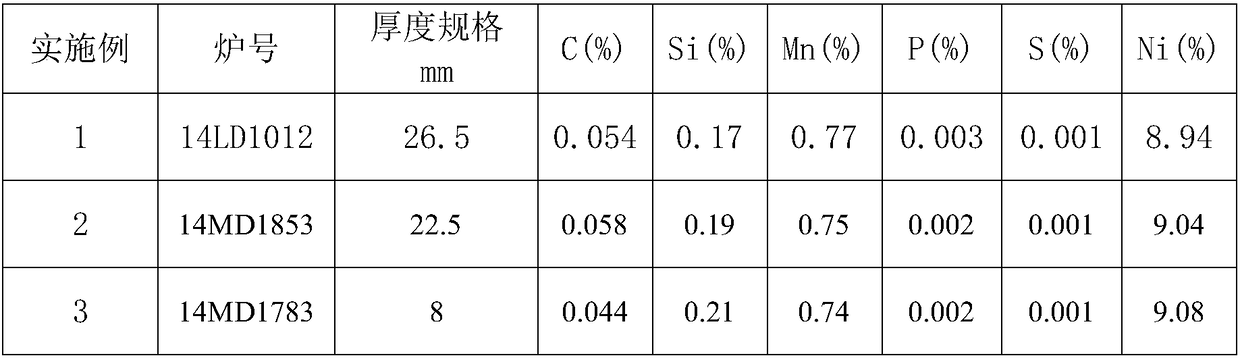

[0038] Table 2: Chemical composition of the steel plates of Examples 1-3

[0039]

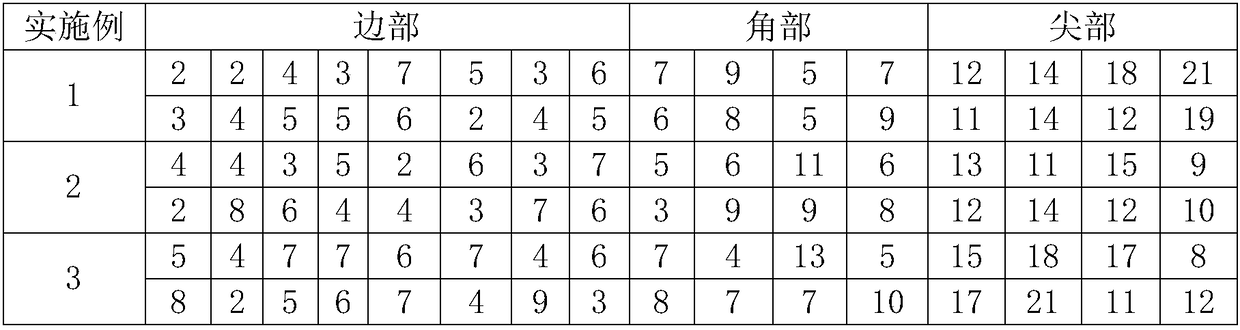

[0040] Table 3: Actual remanence measurement records of the steel plates of Examples 1-3 Unit: Gauss

[0041]

[0042] The above measurement results are all less than 30 Gauss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com