Rare earth precipitation device and rare earth precipitation method

A precipitation device and rare earth technology, applied in the direction of improving process efficiency, can solve problems such as unstable crystal quality of rare earth, achieve uniform pH distribution in liquid phase, improve operating environment, and improve use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

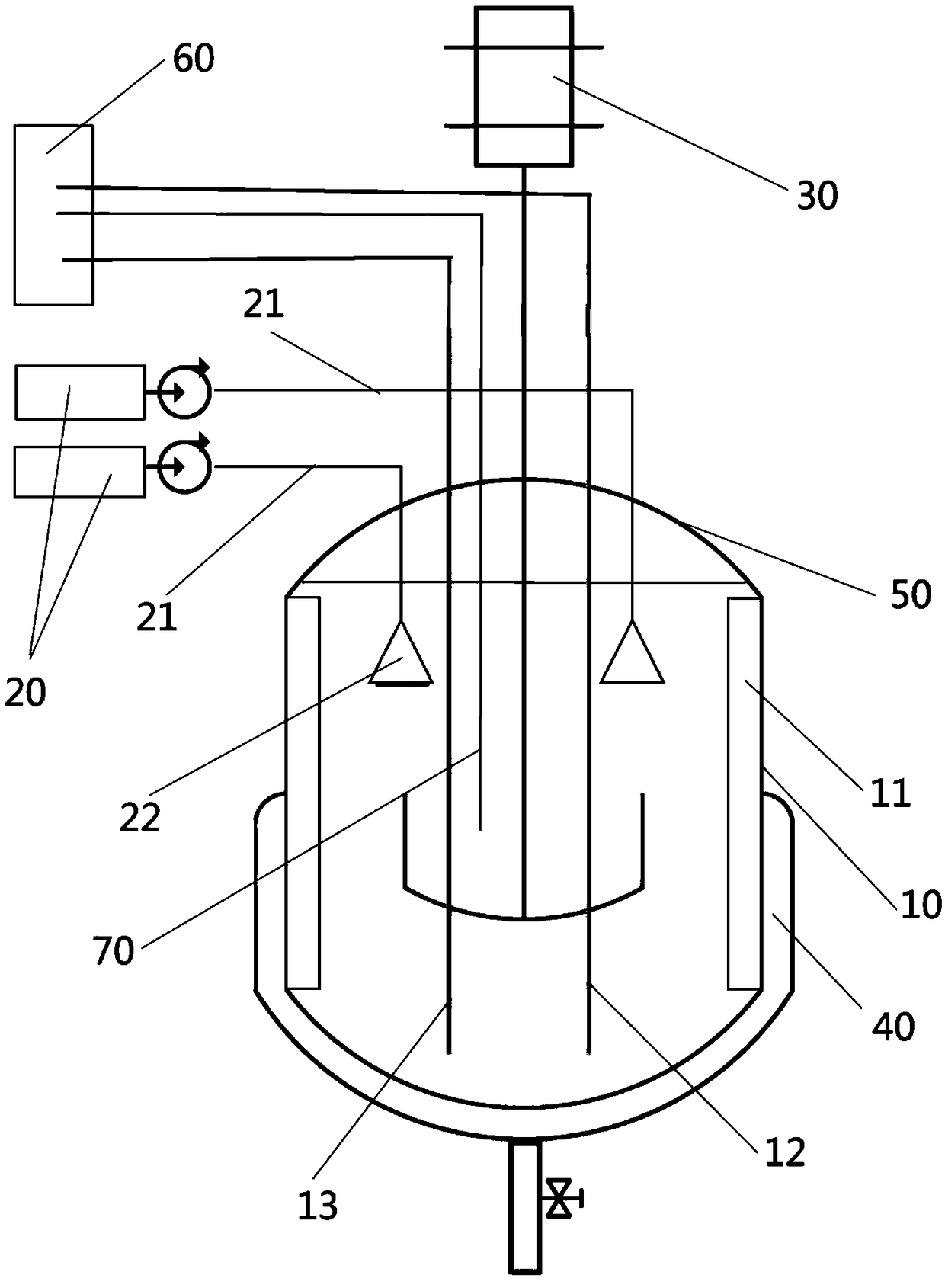

[0062] use figure 1 The rare earth precipitation device shown performs the following process.

[0063] Rare earth solution (concrete composition is shown in table 1) and rare earth precipitating agent (concentration is the ammoniacal liquor of 12wt%) by feeder respectively by the rate of 10mL / min and 9mL / min into the settling tank, rare earth precipitating agent in The injection surface at the bottom of the precipitation container and the injection surface of the rare earth solution at the bottom of the precipitation container overlap by 70-95%. The precipitation temperature is set at 50°C, and the temperature is regulated by a temperature controller; after the precipitation is completed, continue to keep warm for 30 minutes. During the precipitation process, the sedimentation tank is sealed with an air condensation hood, and the pressure controller is used to adjust the pressure of the closed environment to 0.1MPa. During the precipitation process, the pH value of the materi...

Embodiment 2

[0071] Rare earth solution (concrete composition as shown in table 1) and rare earth precipitant (concentration is the ammonium aqueous solution of 14wt%) are squeezed in the precipitation tank by the speed of 10mL / min and 9mL / min respectively by feeder, and precipitation temperature is set Set at 90°C, and use the temperature controller to adjust the temperature to adjust the precipitation; after the precipitation is completed, continue to keep warm for 30 minutes. During the precipitation process, the sedimentation tank is sealed with an air condensation hood, and the pressure of the closed environment is adjusted to 0.15MPa by a pressure controller. During the precipitation process, the pH value of the material is monitored by a pH meter, and the pH value is controlled between 7 and 8. During the precipitation process, the motor drives the stirring paddle to rotate, and the clockwise and counterclockwise rotation speeds are 20 to 300 rpm. The chemical composition of the pre...

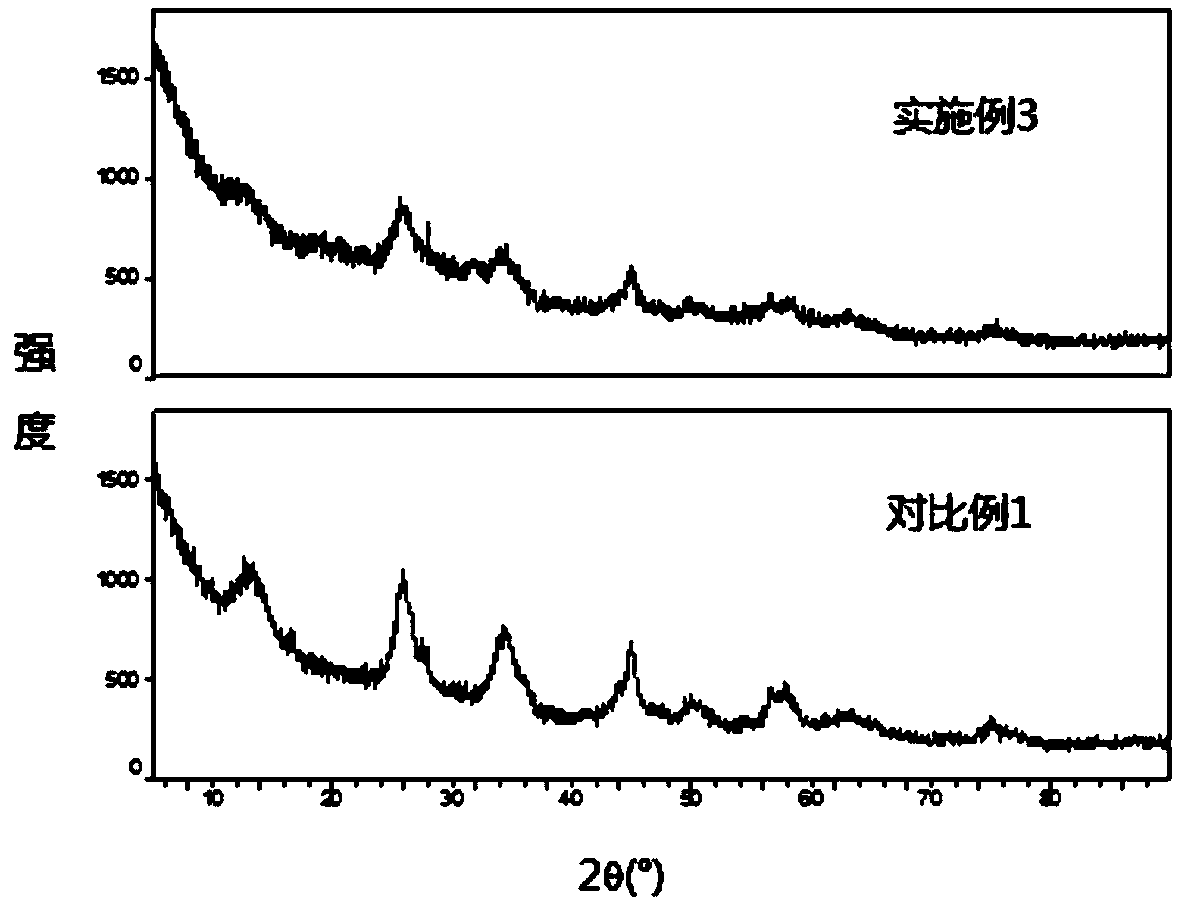

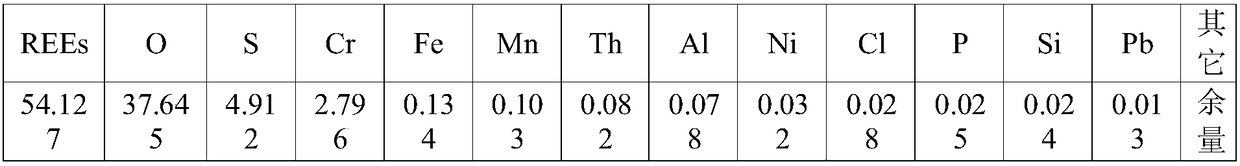

Embodiment 3

[0077] The difference from Example 1 is that the precipitation temperature is set at 60°C. The rare earth precipitation agent is oxalic acid with a concentration of 0.25-0.35 mol / L. The chemical composition of the precipitated samples analyzed by XRF is shown in Table 7. The particle size analysis method is the same as above, and the particle size distribution information is shown in Table 6.

[0078] Table 6

[0079] Median diameter (D50): 14.01μm

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com