A plasma spraying device

A spraying device, plasma technology, applied in the direction of coating, molten spraying, metal material coating technology, etc., can solve the problems of ineffective heat dissipation and sound insulation, low spraying efficiency, etc., to reduce the spread of noise, improve service life, The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

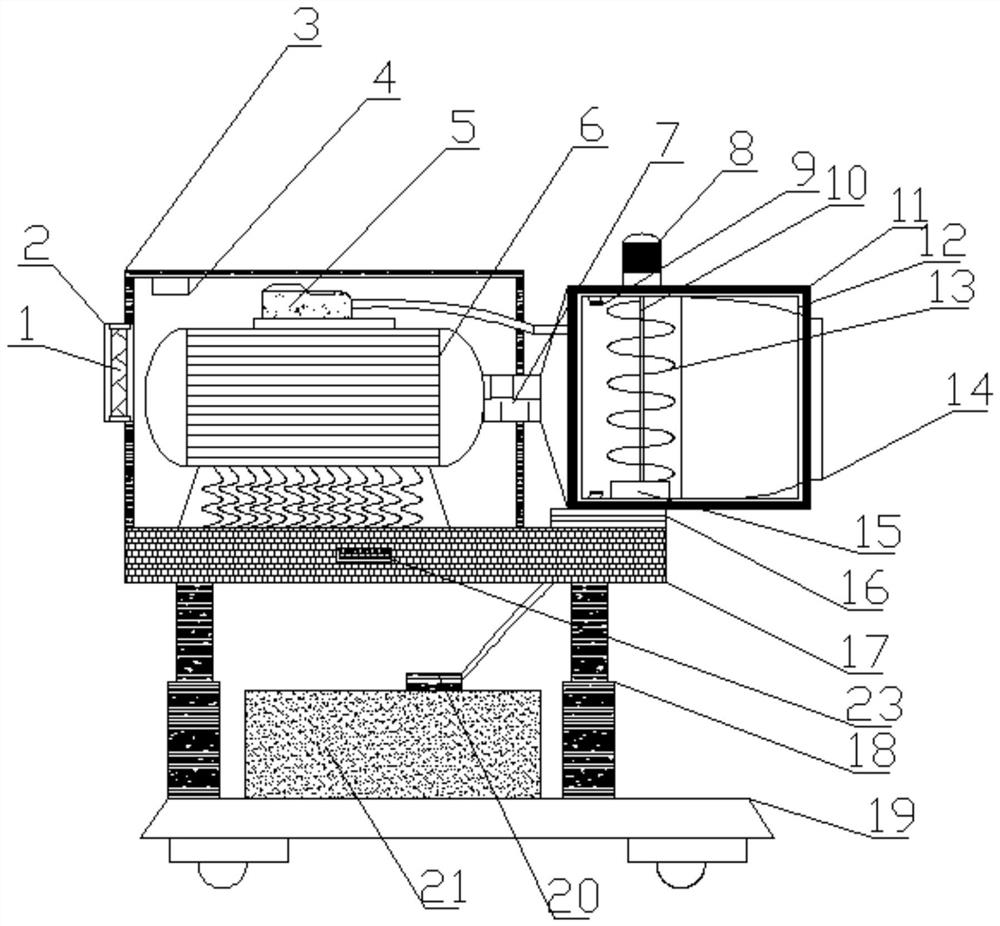

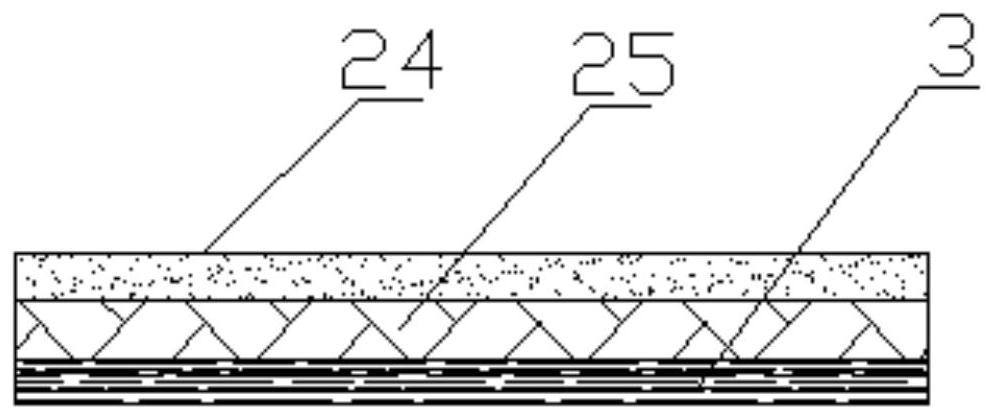

[0022] Such as Figure 1-2 As shown, a plasma spraying device includes a base 19, a workbench 17, a protective cover 3 and a mixing box 11, the top of the base 19 is equipped with an electric hydraulic cylinder 18 through bolts, and the electric hydraulic cylinder 18 is installed by A paint box 21 is installed on the board, and the top of the paint box 21 is provided with a pressure pump 20 through a mounting piece, the output shaft of the electric hydraulic cylinder 18 is installed with a workbench 17 through a bolt, and one side of the workbench 17 passes through a mounting groove A level sensor 23 is provided, and the top of the workbench 17 is connected with a protective cover 3 through a rotating shaft. One side of the protective cover 3 is provided with an air inlet 2, and a cooling fan 1 is installed in the air inlet 2 by screws. The inner top of the protective cover 3 is provided with a temperature controller 4 through the installation slot, the inner bottom of the pro...

Embodiment 2

[0036] Such as Figure 1-2As shown, a plasma spraying device includes a base 19, a workbench 17, a protective cover 3 and a mixing box 11, the top of the base 19 is equipped with an electric hydraulic cylinder 18 through bolts, and the electric hydraulic cylinder 18 is installed by A paint box 21 is installed on the board, and the top of the paint box 21 is provided with a pressure pump 20 through a mounting piece, the output shaft of the electric hydraulic cylinder 18 is installed with a workbench 17 through a bolt, and one side of the workbench 17 passes through a mounting groove A level sensor 23 is provided, and the top of the workbench 17 is connected with a protective cover 3 through a rotating shaft. One side of the protective cover 3 is provided with an air inlet 2, and a cooling fan 1 is installed in the air inlet 2 by screws. The inner top of the protective cover 3 is provided with a temperature controller 4 through the installation slot, the inner bottom of the prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com