Er-Ho-Pr tri-doped lead fluoride mid-infrared laser crystal and preparation method thereof

A hybrid lead fluoride, infrared laser technology, applied in chemical instruments and methods, lasers, crystal growth and other directions, to achieve the effect of reducing life, achieving spectral broadening, and improving energy transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment discloses a kind of erbium holmium praseodymium (Er 3+ 、Ho 3+ 、Pr 3+ ) triple-doped lead fluoride (PbF 2 ) laser crystal, the chemical formula of the crystal is Er x Ho y PR z :Pb 1-x-y-z f 2 , wherein x=0.1~30mol.%, is the molar percentage of Er ion accounting for Pb ion in the matrix, y=0.1~10mol.%, is the molar percentage of Ho ion accounting for Pb ion in the matrix, z=0.1~5mol.%, is the molar percentage of Pr ions to Pb ions in the matrix.

[0023] Erbium (Er 3+ ) and holmium (Ho 3+ ) at the same time as the active ion, praseodymium (Pr 3+ ) as deactivating ions.

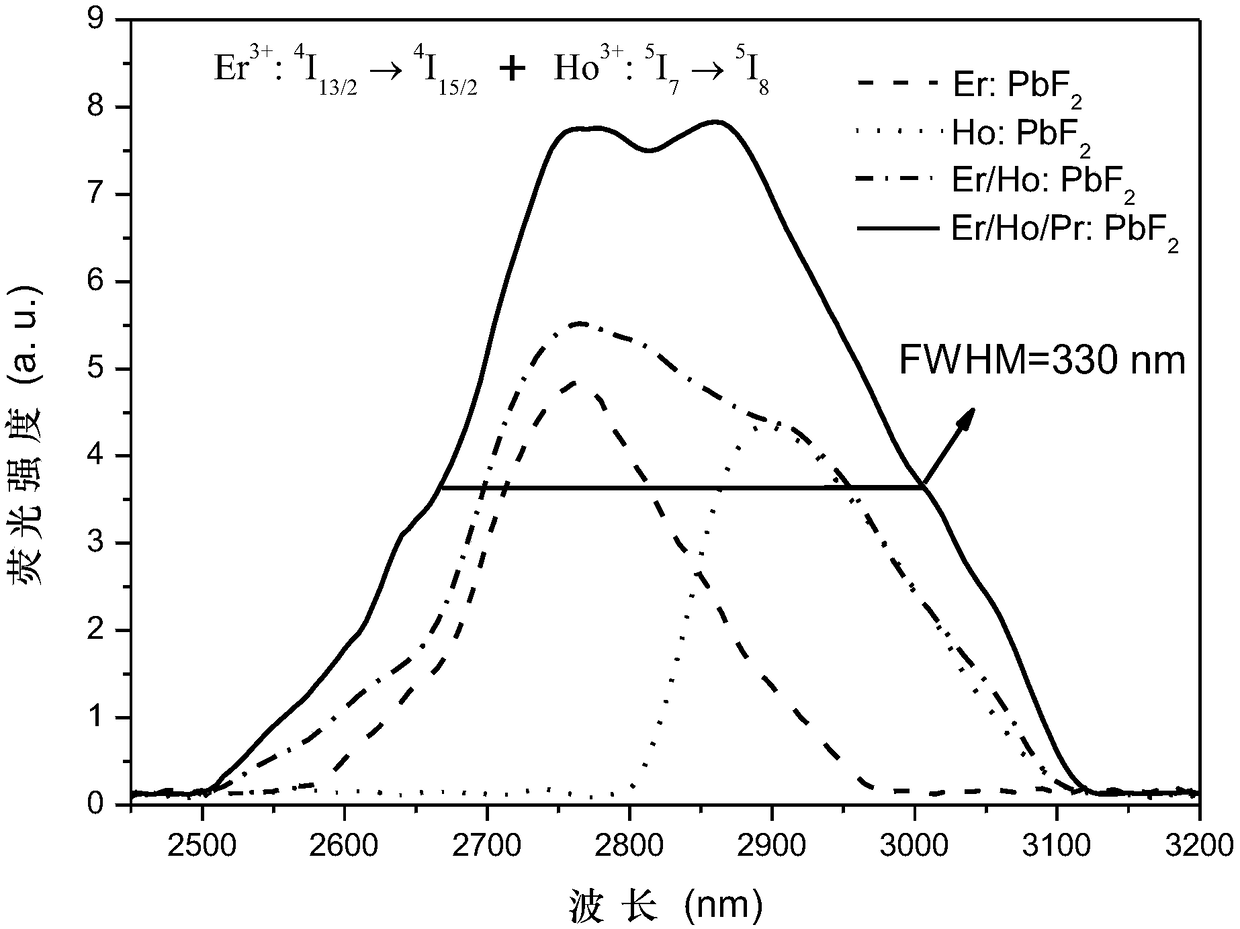

[0024] The laser crystal is used to realize all-solid-state tuned laser output in the 2.5-3.1 micron band.

Embodiment 2

[0026] Er 0.01 Ho 0.01 PR 0.005 Pb 0.975 f 2 Crystal preparation

[0027] The raw materials ErF3, HoF3, PrF3 and PbF2 with a purity greater than 99.999% are uniformly mixed according to the molar ratio of the batching equation in the above-mentioned embodiment 1, and then put into a graphite crucible with a sharp bottom of Φ20×150mm in size, and the crucible is sealed. The crucible is placed in the melting material in the high-temperature zone with a temperature of 1000 ° C in the descending furnace for 8 hours, and then the crucible is lowered at a rate of 1 mm / h. At this time, the temperature gradient within the range of ± 0.5 cm at the crystal solid-liquid interface is 24 ° C / cm, and cooled to room temperature at a rate of 30°C / h after the growth. After the crystal was taken out, it was processed into a sample of 8×8×1mm3 for spectral testing. The fluorescence spectrum was as follows: figure 1 shown.

Embodiment 3

[0029] Er 0.02 Ho 0.02 PR 0.01 Pb 0.95 f 2 Crystal preparation

[0030] The raw materials ErF3, HoF3, PrF3 and PbF2 with a purity greater than 99.999% are uniformly mixed according to the molar ratio of the batching equation in the above-mentioned embodiment 1, and then put into a graphite crucible with a sharp bottom of Φ30×100mm in size, and the crucible is sealed. Put the crucible in a descending furnace in a high temperature zone of 1050°C for 10 hours, and then lower the crucible at a rate of 0.8mm / h. At this time, the temperature gradient within ±0.5cm at the crystal solid-liquid interface is 36°C / cm, and cooled to room temperature at a rate of 40°C / h after the growth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com