Prefabricated superposed reinforced concrete bridge pier structure

A reinforced concrete and prefabricated assembly technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of insufficient connection integrity of prefabricated bridge pier structures, high degree of mechanization, and long construction period, so as to save manpower and material resources and reduce environmental pollution , the effect of improving the level of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

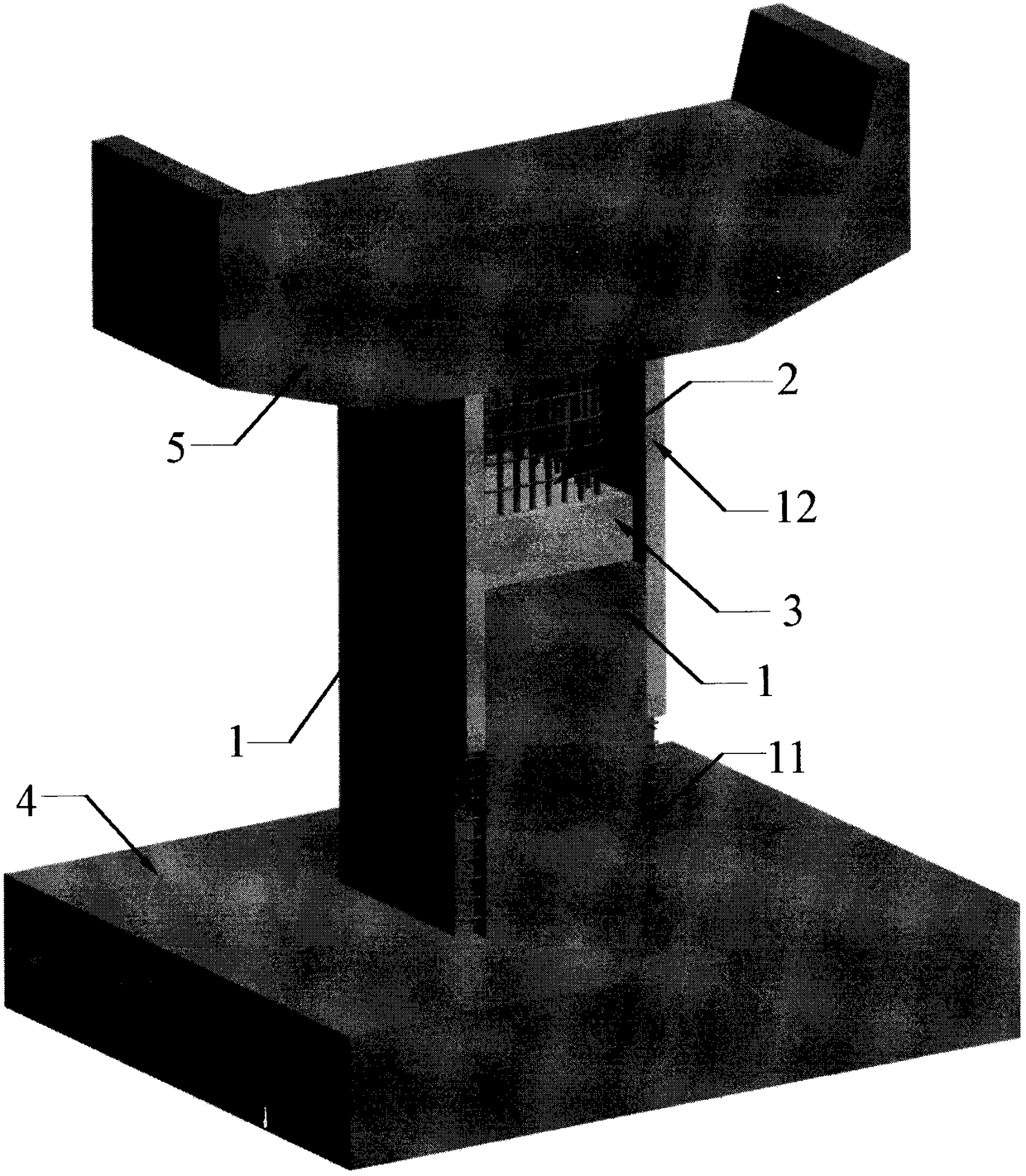

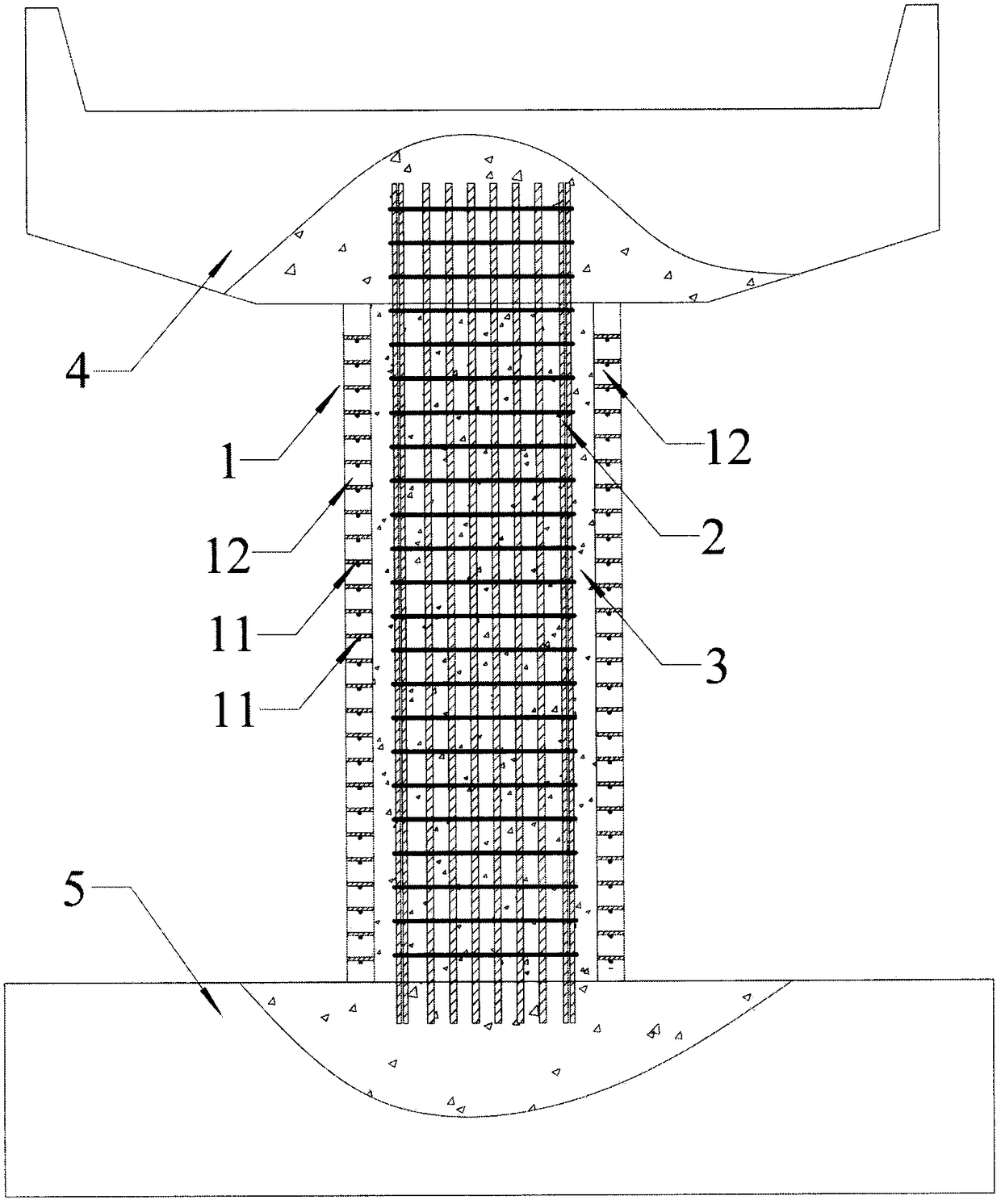

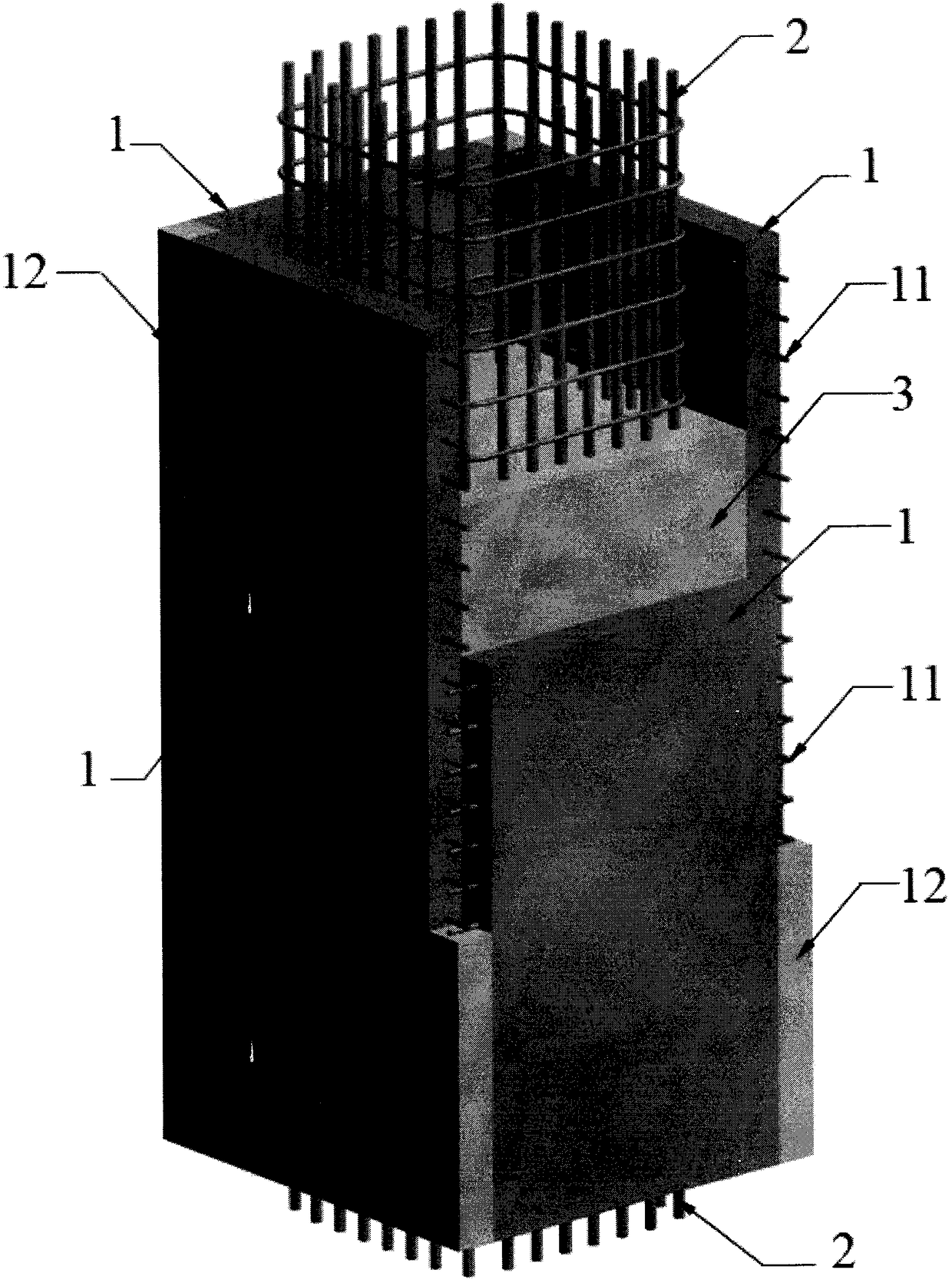

[0030] A prefabricated composite reinforced concrete pier structure, including prefabricated reinforced concrete pier pieces 1, steel skeleton 2, and cast-in-place core concrete 3. During implementation, the reinforced concrete is pre-cast with ultra-high performance concrete with a compressive strength greater than 100MPa Thin-walled sheets form prefabricated reinforced concrete piers 1, and the inner surface of the prefabricated reinforced concrete piers 1 is provided with a bonding structure such as unevenness, sandblasting, scratching or studs, and several prefabricated reinforced concrete piers 1 are connected at the joints. Buried the connecting bars 11; transported and hoisted the prefabricated reinforced concrete piers 1 to the site, and arranged multiple prefabricated reinforced concrete piers 1 along the outer edges of the pier cross-section in a circular lap arrangement, and the adjacent prefabricated reinforced concrete piers 1 were prefabricated Embedded connecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com