Hot-humid climate suitability assembly type bamboo wood-porous material combination exterior wall

A porous material, wet climate technology, used in climate change adaptation, walls, building components, etc., can solve the problems of no combination of passive evaporative cooling technology, increased wall thickness, limited effect, etc., to achieve good application prospects, avoid two problems. Sub-decoration, the effect of good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

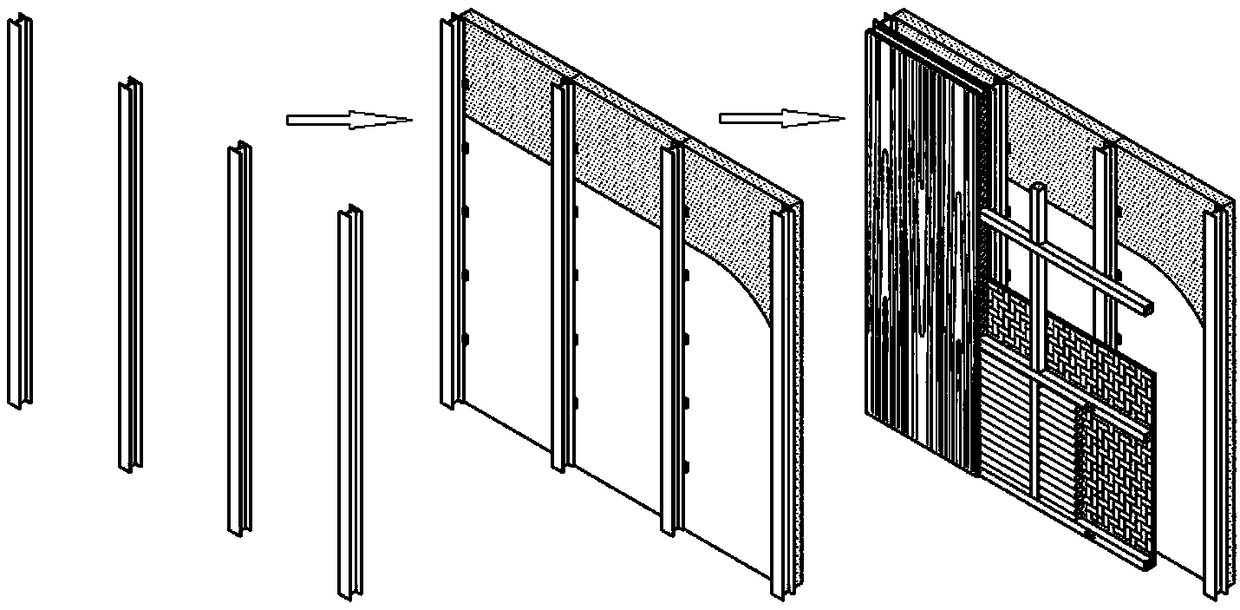

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

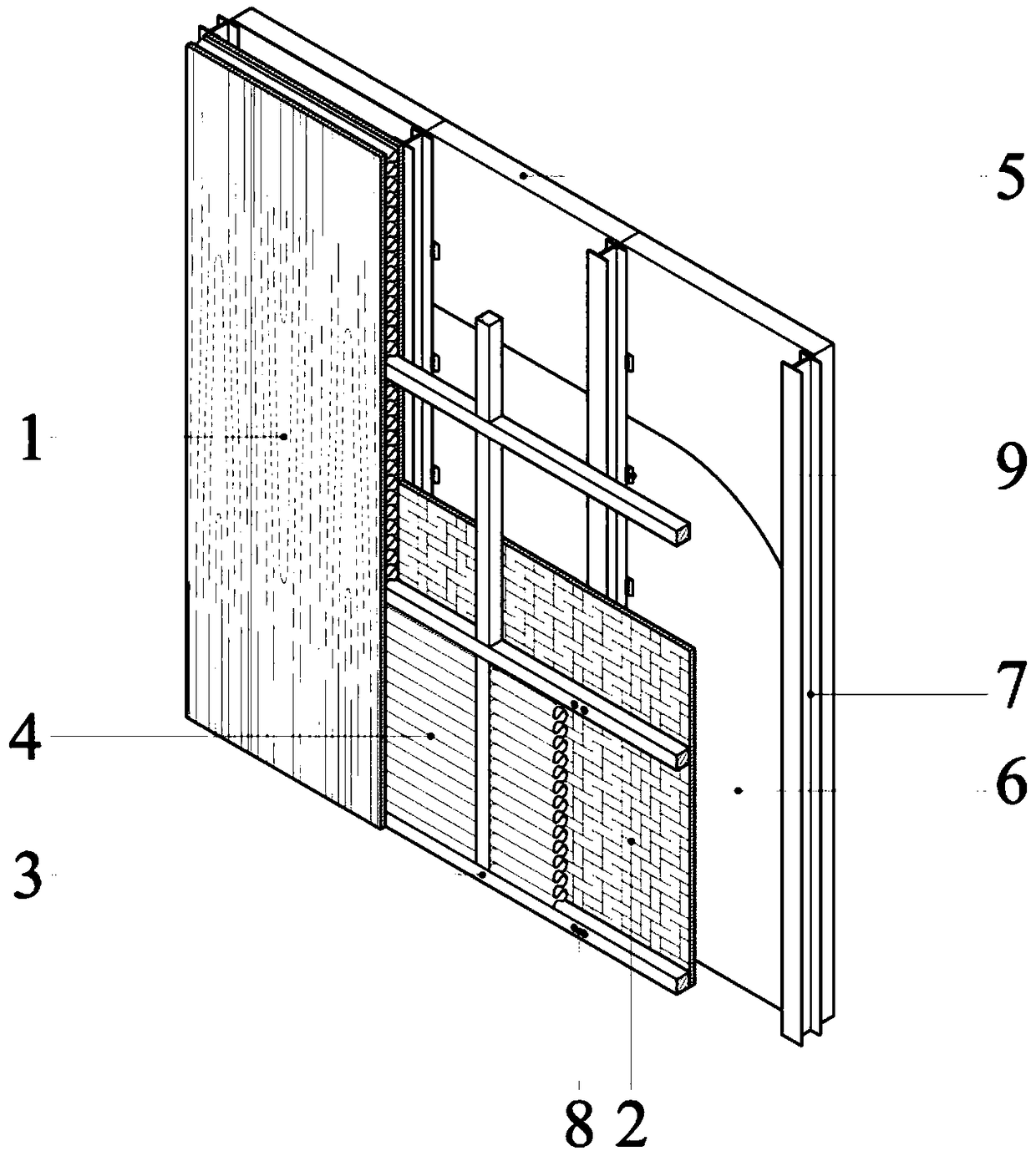

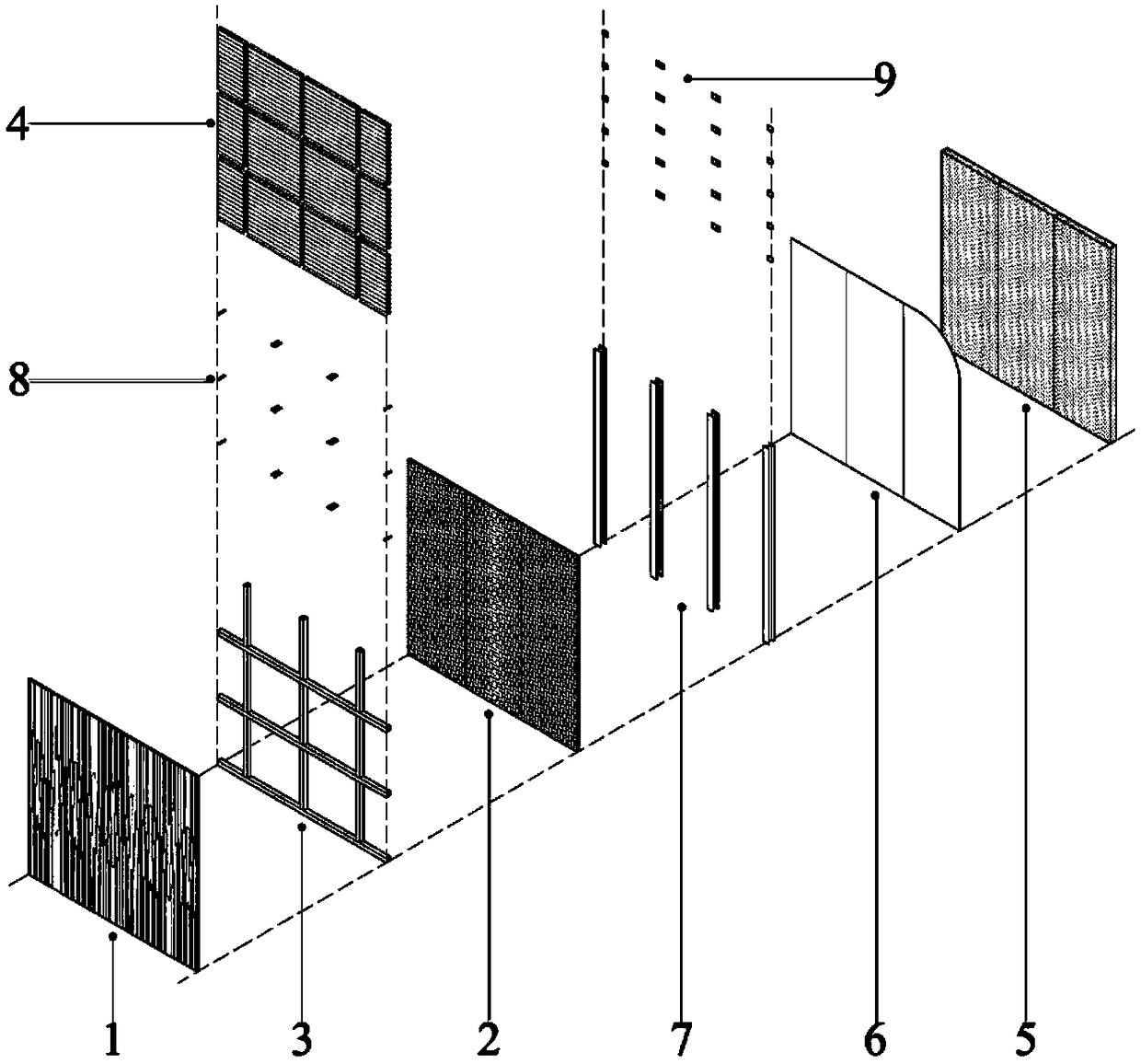

[0020] A prefabricated bamboo wood-porous material composite exterior wall suitable for hot and humid climates, which includes an internal module and an external module, and the internal module and the external module are connected by section steel longitudinal rods.

[0021] The internal modules include bamboo and wood inner panels, interlayers, and bamboo and wood partitions. Bamboo and wood inner panels should be selected with good appearance quality, high steam penetration resistance, and good sound insulation. The thickness should be 28mm. Bamboo-wood partition boards should be made of board materials with high mechanical strength and low steam penetration resistance, and the thickness should be 18mm. In the interlayer, the internal support is anchored by cross bars and section steel longitudinal bars, and the longitudinal bars of the internal support a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com