Shock-induced ignition ramjet engine and method for shock-induced ignition ramjet

A ramjet and shock wave technology, applied in ramjet engines, machines/engines, gas turbine devices, etc., can solve the problems that fuel and gas cannot be fully mixed and completely burned, affect engine propulsion performance, and increase engine structure. Achieve the effect of reducing weight, light structure quality and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

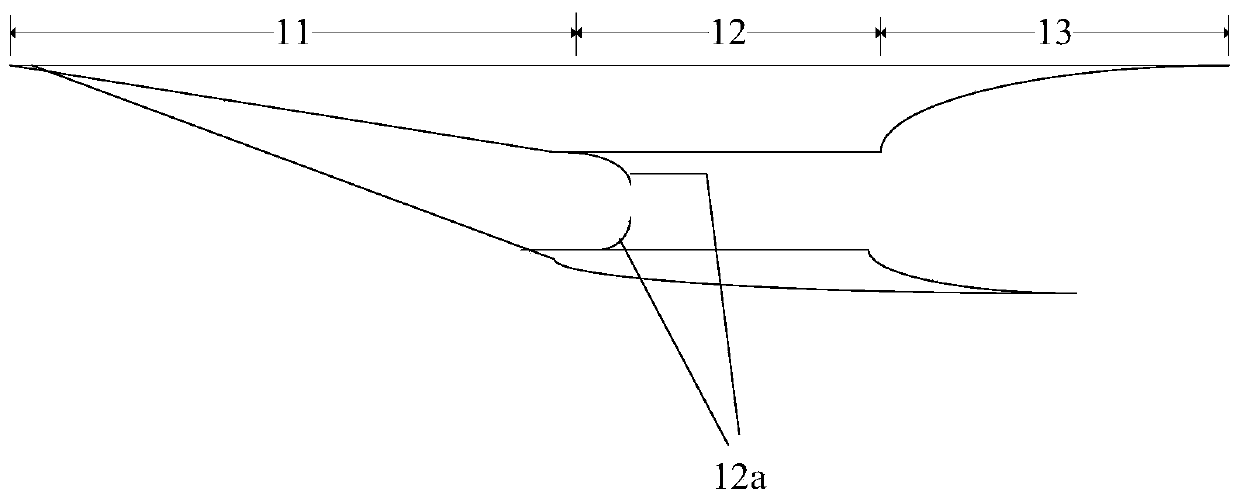

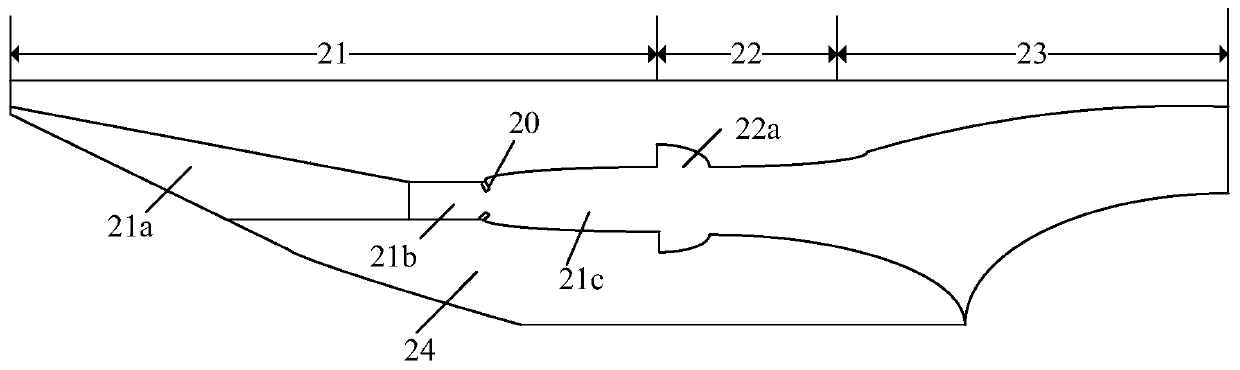

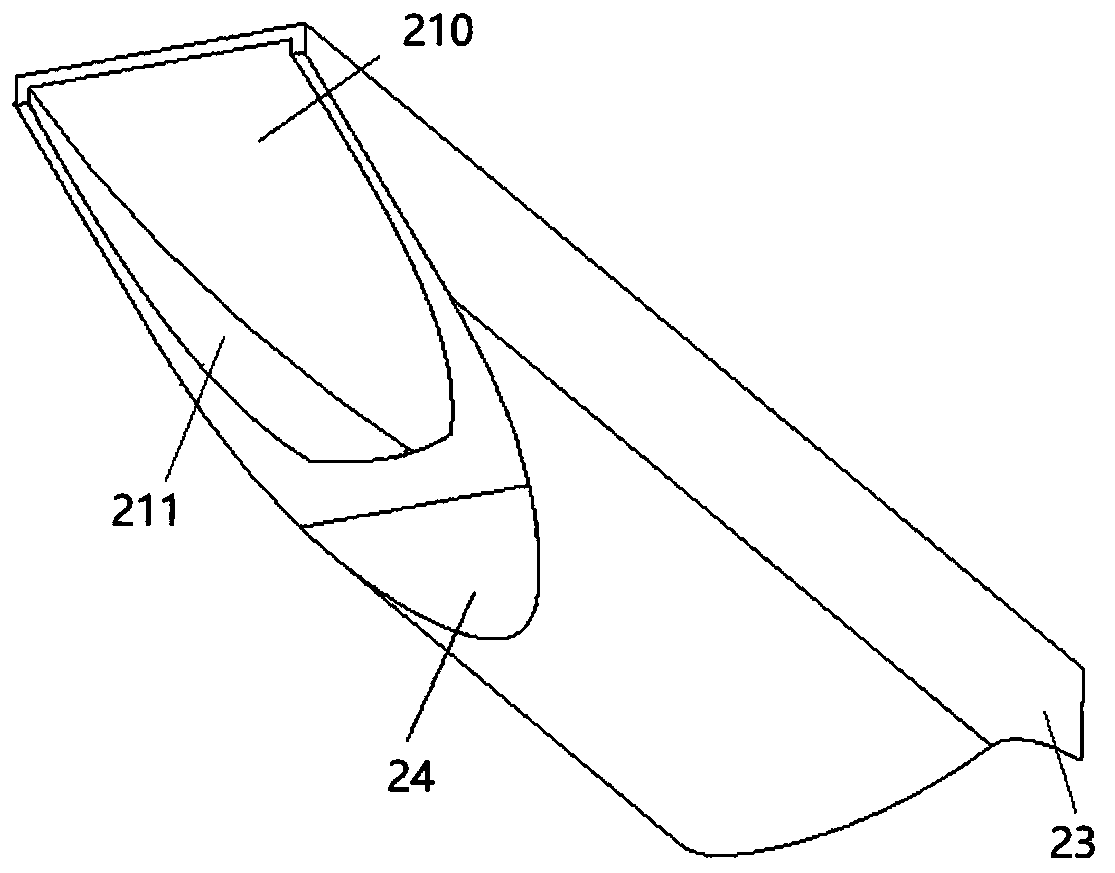

[0037] figure 2 It is a schematic diagram of a plane structure of a shock-induced combustion ramjet engine according to an embodiment of the present invention.

[0038] The shock-induced combustion ramjet engine includes: a fuel injector 20, a square-turn-circular internally retractable intake port 21, a combustion chamber 22, and a tail nozzle 23. The square-turn inner-contracting intake port 21 includes a first intake port section 21a, a second intake port section 21b, and a mixing section 21c. The first intake port section 21a includes the inner cavity of the first intake port section 21a. The first wall surface 210 and the second wall surface 211, the first wall surface 210 is a flat surface, the second wall surface 211 is an arc surface, and the first air inlet section 21a gradually moves from the inlet to the second air inlet section 21b. When contracted, the second air inlet section 21b communicates with the first air inlet section 21a, which is cylindrical, and the mixin...

Embodiment 2

[0049] In this embodiment, the shock-induced ignition ram-launching method includes the following steps: setting the intake port as a square-turn-circle inward-contracting intake port to include a first intake port section and a second intake port section And the mixing section, the first intake port section includes a first wall surface and a second wall surface constituting the inner cavity of the first intake port section, the first wall surface is a flat surface, the second wall surface is an arc surface, and the first intake port section is From the inlet to the second inlet section, it gradually shrinks, the second inlet section is connected with the first inlet section, which is cylindrical, and the mixing section is connected with the second inlet section; The fuel injector is set at the entrance of the mixing section; when the hypersonic flow enters the mixing section, the fuel injector injects fuel; the hypersonic flow is compressed in the first and second intake port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com