Drying method for tirofiban hydrochloride

A drying method, tirofiban technology, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of many impurities, high moisture, poor appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

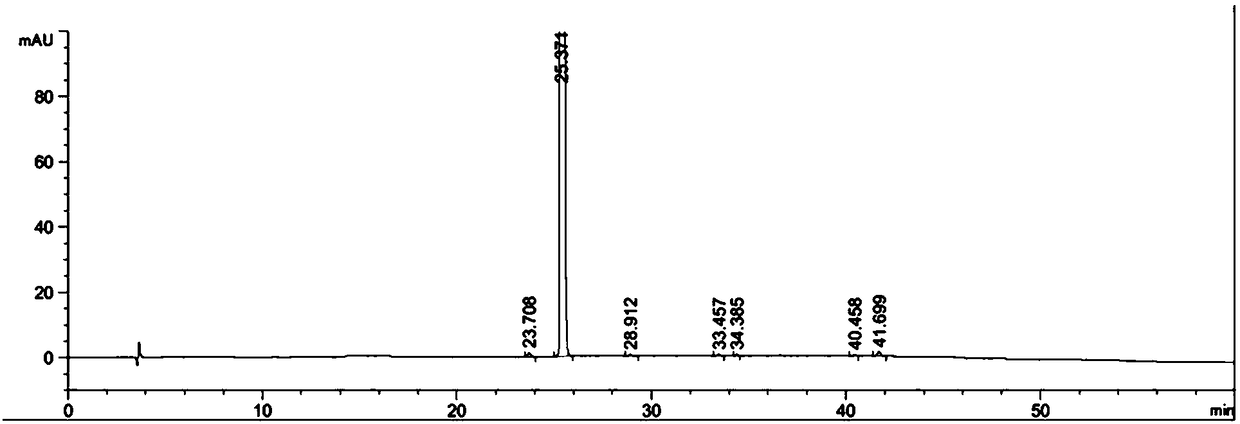

Embodiment 1

[0021] Take an appropriate amount of tirofiban hydrochloride wet product, and the moisture content of the tirofiban hydrochloride wet product is 8.55%. Adopt high-efficiency boiling dryer to carry out boiling drying to tirofiban hydrochloride wet product, the power of high-efficiency boiling dryer is 2.3kw. The process conditions are: drying temperature 44°C, drying time 10 minutes, air flow 70m 3 / h.

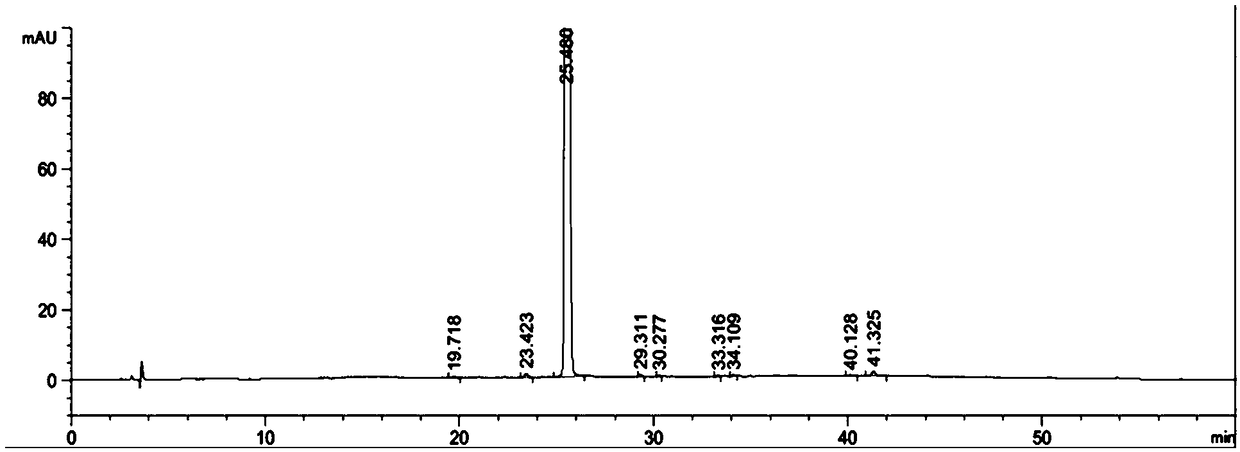

Embodiment 2

[0023] Take an appropriate amount of tirofiban hydrochloride wet product, and the moisture content of the tirofiban hydrochloride wet product is 8.55%. Adopt high-efficiency boiling dryer to carry out boiling drying to tirofiban hydrochloride wet product, the power of high-efficiency boiling dryer is 2.3kw. The process conditions are: drying temperature 41°C, drying time 12 minutes, air flow 60m 3 / h.

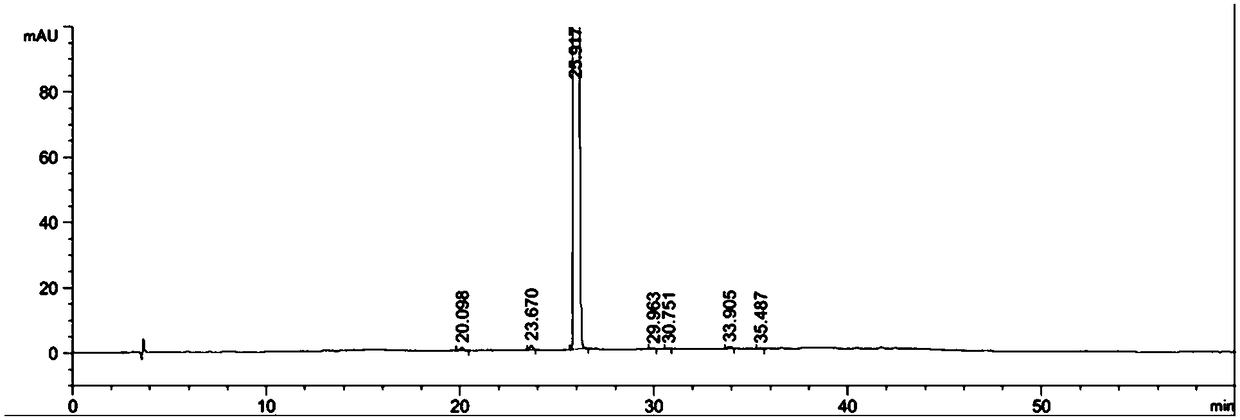

Embodiment 3

[0025] Take an appropriate amount of tirofiban hydrochloride wet product, and the moisture content of the tirofiban hydrochloride wet product is 8.55%. Adopt high-efficiency boiling dryer to carry out boiling drying to tirofiban hydrochloride wet product, the power of high-efficiency boiling dryer is 2.3kw. The process conditions are: drying temperature 43°C, drying time 15 minutes, air flow 45m 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com