A large-core high-density sleeve optical cable

A high-density, large-core technology, applied in optics, light guides, optical components, etc., can solve the problems of unfavorable cleaning construction, low fiber core number and density, etc., to ensure normal water resistance and tensile properties, improve fabric The effect of density and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described and illustrated below in conjunction with the accompanying drawings and embodiments.

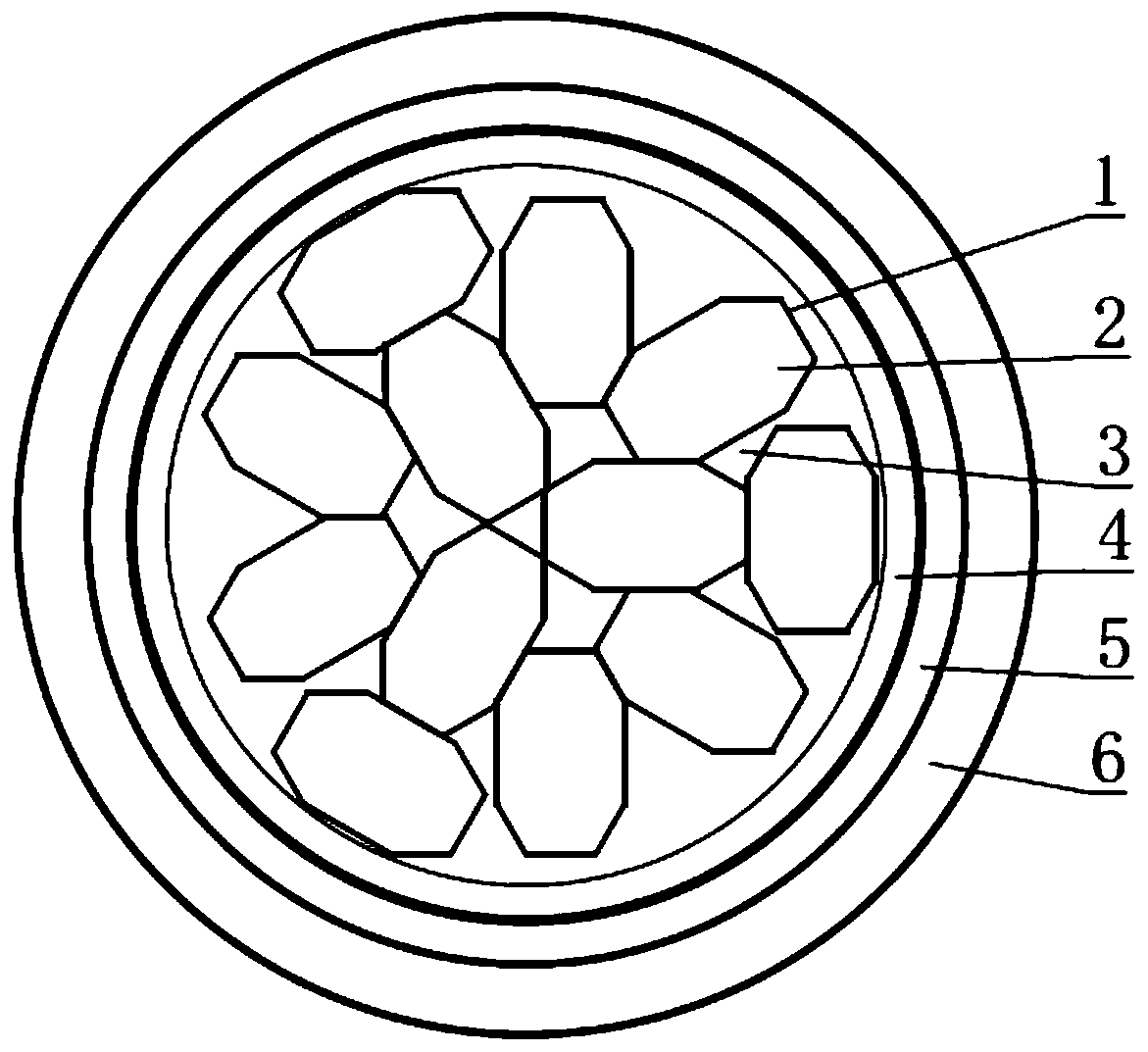

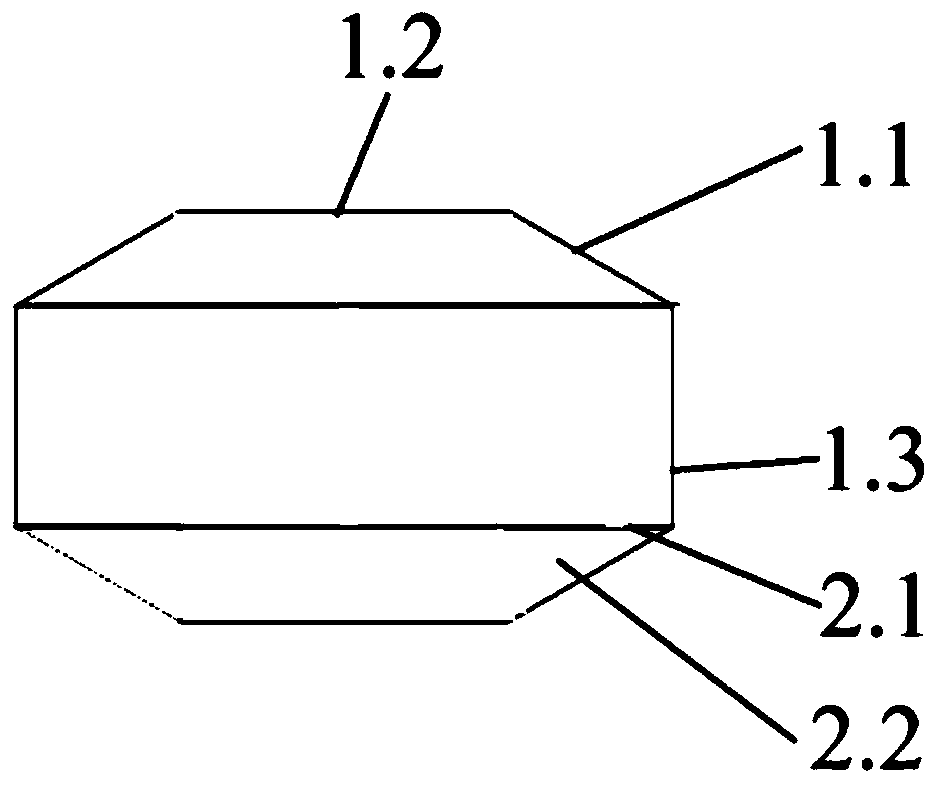

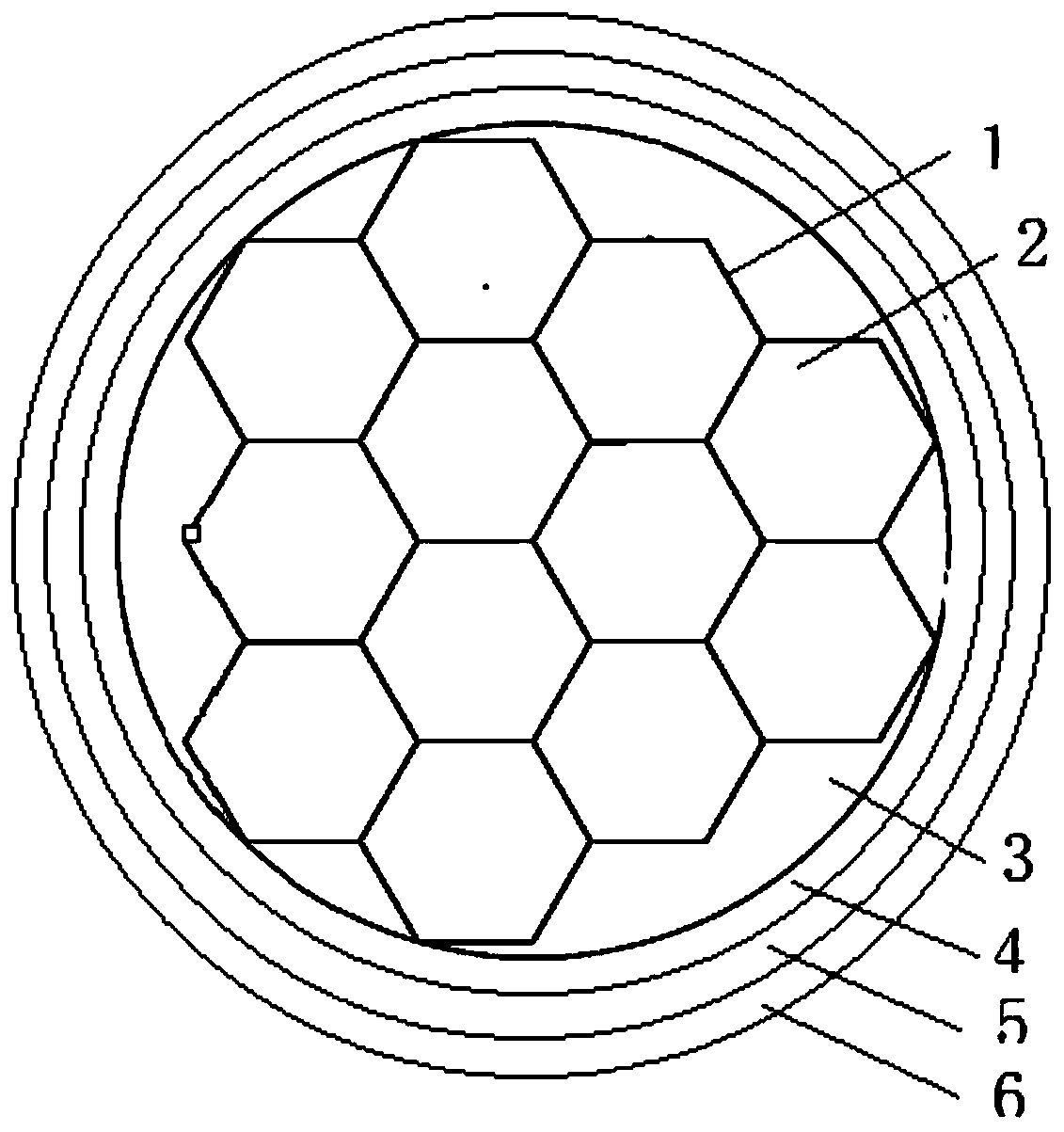

[0021] The first embodiment of the present invention is figure 1 , 2 As shown, it includes an outer sheath 6 and a loose tube 1 wrapped in the outer sheath. The loose tube is a long 8-sided loose tube, and the long 8-sided shape includes 2 symmetrically arranged up and down. The long side 1.2 and the two short sides 1.3 symmetrically arranged on both sides, the ratio of the long side to the short side is 1.3~1.7︰1, the two long sides and the two short sides are connected by the hypotenuse 1.1 at the four corners to form a long 8 polygons. The radial cross-section of the outer sheath is circular, and the loose tube is laid in two layers around the center of the outer sheath, the inner layer is provided with 3 loose tubes, and the outer layer is provided with 9 loose tubes, wherein the inner layer The three loose tubes in the outer laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com