An aeroengine residual life prediction method based on multi-stage consistency check

A technology for aero-engine and life prediction, applied in computer-aided design, special data processing applications, instruments, etc., can solve problems such as poor prediction accuracy and failure to take into account the multi-stage performance, so as to improve accuracy and reduce Measuring error, estimating the effect of accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

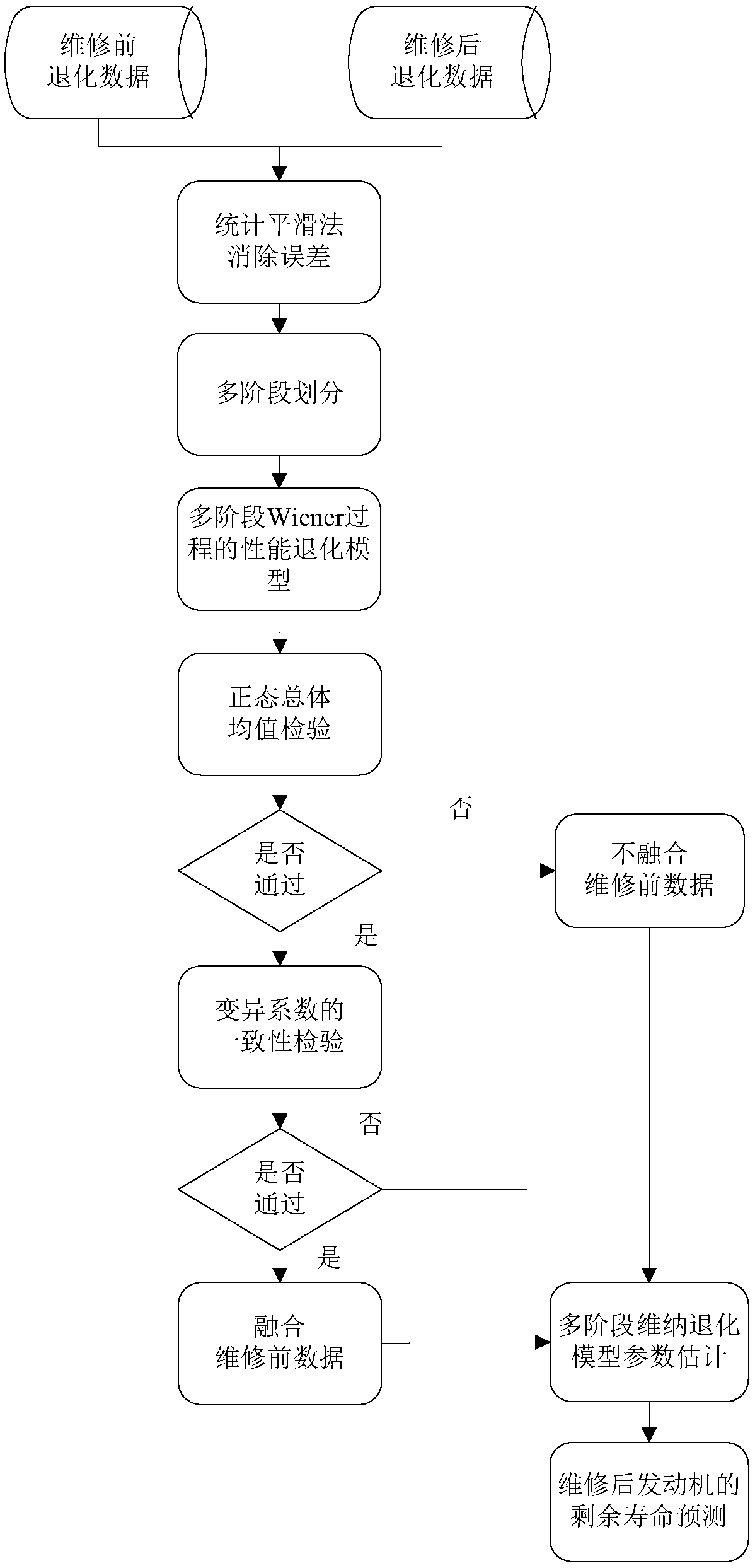

[0024] refer to figure 1 As shown, the aeroengine residual life prediction method based on multi-stage Wiener process consistency check of the present invention mainly comprises two parts of consistency check and life prediction;

[0025] The consistency check part includes: data processing, used to remove the influence of factors such as power frequency noise, background noise and random pulse interference on the pure signal; multi-stage division, used to divide the non-stationary monitoring time series into stages; The normal overall mean consistency test of the stage Wiener process is used to test whether the mean value of the engine monitoring data before maintenance is consistent with that after maintenance; the consistency test of the coefficient of variation based on the multi-stage Wiener process is used to test the engine before main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com