A high-heat-dissipating all-resin casting type busbar groove

A technology of resin casting and high heat dissipation, which is applied in the field of busway, which can solve the problems of busway damage, reduced service life of busway, and high heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

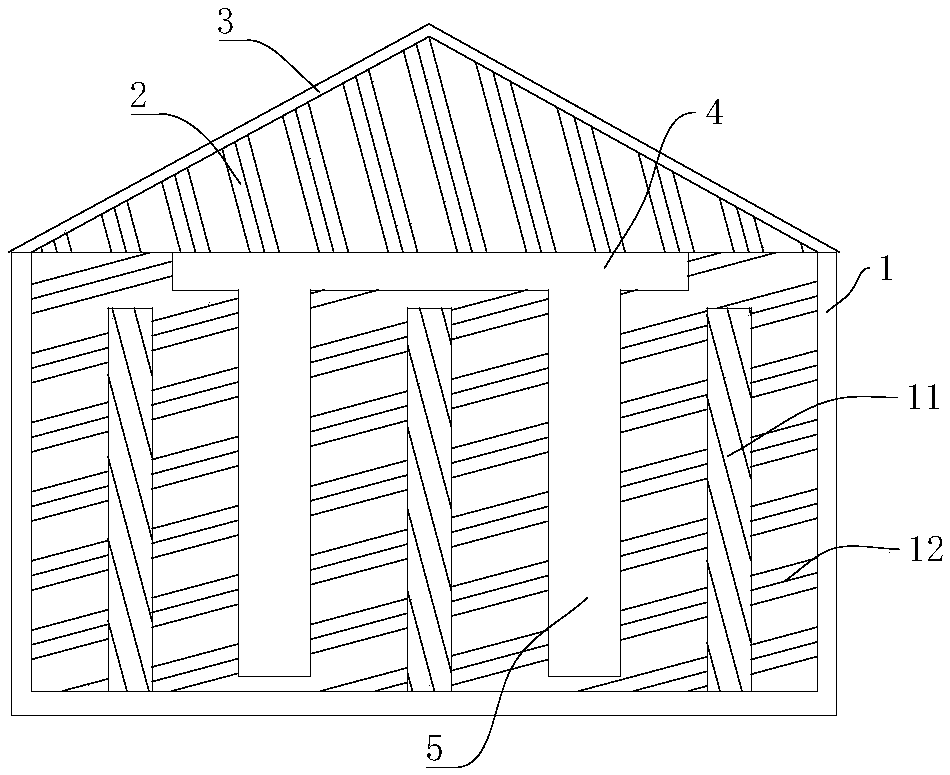

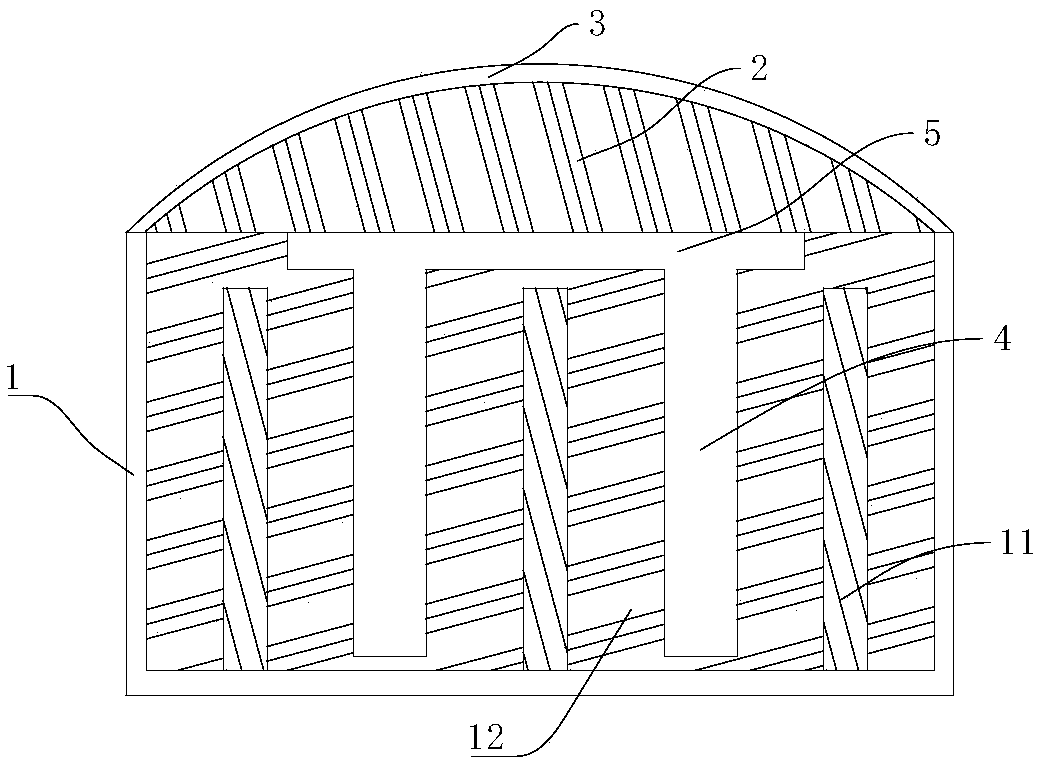

[0026] Embodiment 1: A high heat dissipation full resin cast busway, such as Figure 1-3 As shown, it includes a closed casing 1, and a plurality of bus conductors 11 and composite resin bodies 12 located in the closed casing 1, each bus conductor 11 is wrapped by a composite resin body 12, that is, adjacent bus conductors 11 are composited The resin body 12 is separated to prevent short circuit, the protection grade is IP68, and has the functions of waterproof, fireproof, anticorrosion and explosion-proof.

[0027] A heat conduction block 2 in contact with the composite resin body 12 is arranged on the top of the closed shell 1. The heat conduction block 2 is made of heat conduction silicone grease, and a plurality of heat sinks 3 are evenly distributed on the heat conduction block 2. The heat of the composite resin body 12 is transferred to the heat conduction Block 2, and then dissipate heat through cooling fins 3, so that the heat in the closed casing 1 can be dissipated i...

Embodiment 2

[0035] Example 2: A high heat dissipation all-resin cast busway, the difference from Example 1 is that the high temperature resistant layer includes the following components by weight: EPDM raw rubber: 55kg, silicone resin: 32.5kg , glass fiber 6.5kg, diaminodiphenyl sulfone 5.5kg, dimethyl polysiloxane solution 13kg, epoxy resin 34.5kg, aluminum powder 6kg, high wear-resistant carbon black 8kg, phosphate 2.5kg, modified clay 5kg, mica ceramics 7kg.

[0036] The preparation method of the high temperature resistant layer comprises the following steps:

[0037] a. Add EPDM raw rubber, silicone resin and epoxy resin to the planetary ball mill together, add grinding balls according to the ratio of ball to material (1-3):1, then add glass fiber, glass fiber The amount is 45-50% of the mass of the grinding balls, ball milling at a rate of 300-350 rpm for 2-2.5 hours, and after the ball milling is completed, place it in a drying oven at 350-400°C for 0.5-1 hour to obtain a dry powder;...

Embodiment 3

[0040] Embodiment 3: A high heat dissipation all-resin cast busway. The difference from Embodiment 1 is that the high temperature resistant layer includes the following components by weight: EPDM raw rubber: 60kg, silicone resin: 35kg, Glass fiber 8kg, diaminodiphenyl sulfone 6kg, dimethyl polysiloxane solution 14kg, epoxy resin 35kg, aluminum powder 7kg, high wear-resistant carbon black 9kg, phosphate 4kg, modified clay 6kg, mica ceramics 8kg .

[0041] The preparation method of the high temperature resistant layer comprises the following steps:

[0042] a. Add EPDM raw rubber, silicone resin and epoxy resin to the planetary ball mill together, add grinding balls according to the ratio of ball to material (1-3):1, then add glass fiber, glass fiber The amount is 45-50% of the mass of the grinding balls, ball milling at a rate of 300-350 rpm for 2-2.5 hours, and after the ball milling is completed, place it in a drying oven at 350-400°C for 0.5-1 hour to obtain a dry powder; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com