A kind of glossy and silky matte lipstick and its production process

A silky, matte technology, used in skin care preparations, cosmetics, cosmetic preparations, etc., can solve the problem of low possibility of lip skin absorption, strong mirror gloss on lips, and reduced user experience, etc. problem, to achieve the effect of not easy stickiness, good color fixing effect, and improved experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: A glossy and silky matte lipstick, the components included and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0070] Step 1, mix butyl octanyl salicylate, isohexadecane, diisostearyl malate, silica dimethyl silylate, dimethicone, first emollient, The second emollient, trimethylsiloxysilicate, sorbitan sesquiisostearate, plasticizer, and thickener are heated to 95°C and fully mixed to obtain the first mixture;

[0071] Step 2, cooling the first mixture obtained in step 1 to 75°C, fully mixing the skin conditioner, tocopheryl acetate, and preservatives to obtain the second mixture;

[0072] Step 3, fully mixing the second mixture obtained in step 2 with the first mixture obtained in step 1 to obtain a third mixture;

[0073] Step 4, adding the coloring agent to the third mixture obtained in Step 3, at this time, keep the temperature at 75° C., fully mix to obtain the fourth mixture;

[0074] In ste...

Embodiment 2-5

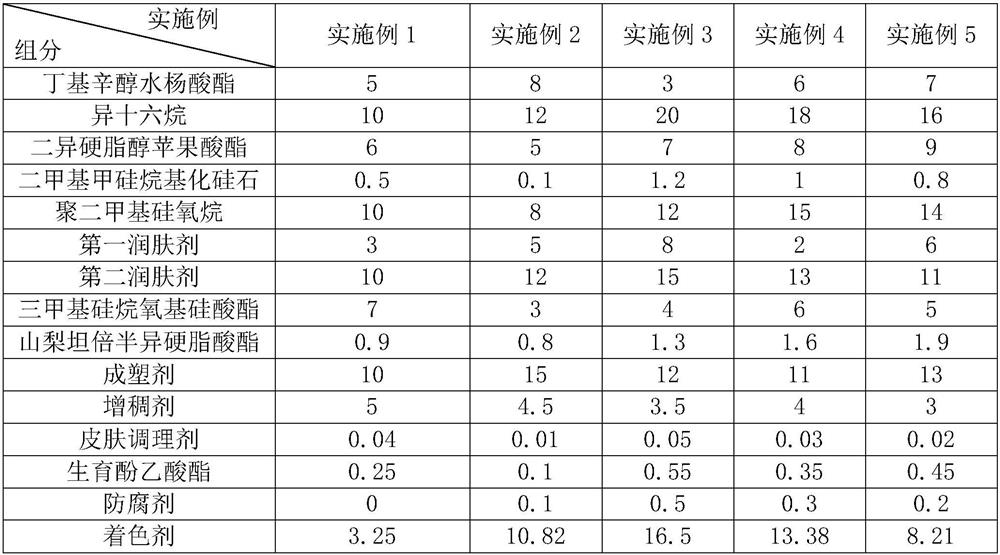

[0080] Example 2-5: a glossy and silky matte lipstick, the difference from Example 1 is that the components included and their corresponding parts by weight are shown in Table 1.

[0081] Components included in Table 1 Embodiment 1-5 and their corresponding parts by weight (parts)

[0082]

Embodiment 6

[0083] Embodiment 6: a glossy and silky matte lipstick, the difference with embodiment 2 is that the first moisturizing agent is composed of C26-28 alkyl polydimethylsiloxane, Composition of polymethylsilsesquioxane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com