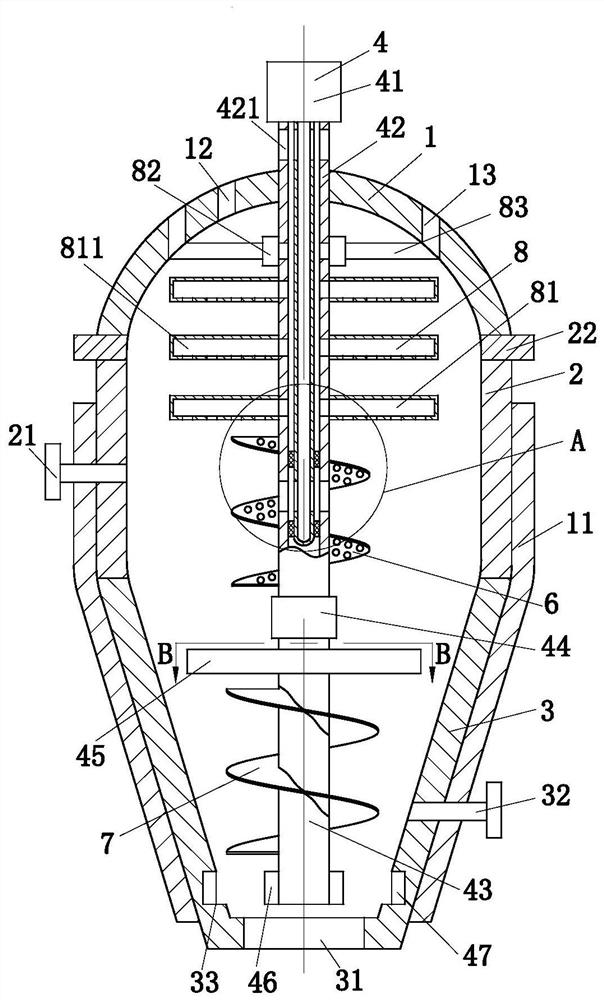

A kind of organosilicon waste liquid treatment system

A waste liquid treatment system and organosilicon technology, applied in the direction of separation methods, chemical instruments and methods, distillation separation, etc., can solve problems such as stirring, confinement, and inability to completely evaporate high boiling substances, so as to improve evaporation efficiency and improve evaporation efficiency. Efficiency, improve the effect of steaming efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

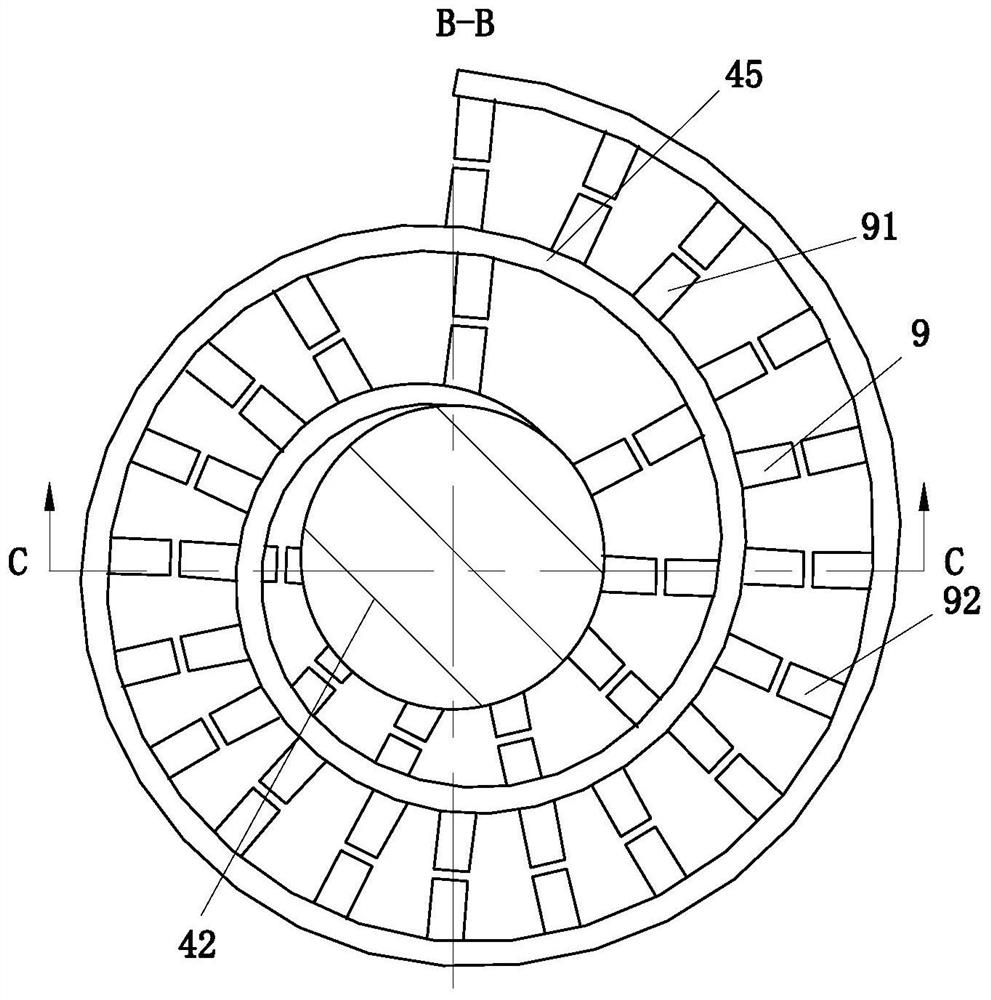

[0038] As an embodiment of the present invention, the No. 1 plate 91 is provided with a No. 1 magnet 93, and the No. 2 plate 92 is provided with a No. 2 magnet 94; the No. 1 magnet 93 and the No. 2 magnet 94 attract each other, The interaction between the No. 1 magnet 93 and the No. 2 magnet 94 is used to stabilize the rotation of the No. 1 plate 91 and the No. 2 plate 92 . The present invention arranges No. 1 magnet 93 and No. 2 magnet 94, through the mutual cooperation between No. 1 magnet 93 and No. 2 magnet 94, avoids No. 1 plate 91 and No. 2 plate 92 in rotation, and the residue after evaporation falls on a In the rotation gap between the No. plate 91 and the No. 2 plate 92, the No. 1 plate 91 and the No. 2 plate 92 cannot be reset, which affects the transportation of the organosilicon waste liquid, thereby improving the evaporation efficiency of the organosilicon waste liquid.

[0039] As an embodiment of the present invention, the No. 2 shaft 43 is provided with a No. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com