Soil remediation method

A soil remediation and soil technology, applied in the field of soil remediation, can solve the problems of high remediation cost and complicated treatment process, and achieve the effect of high hydrophilic ability and slow down the leaching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

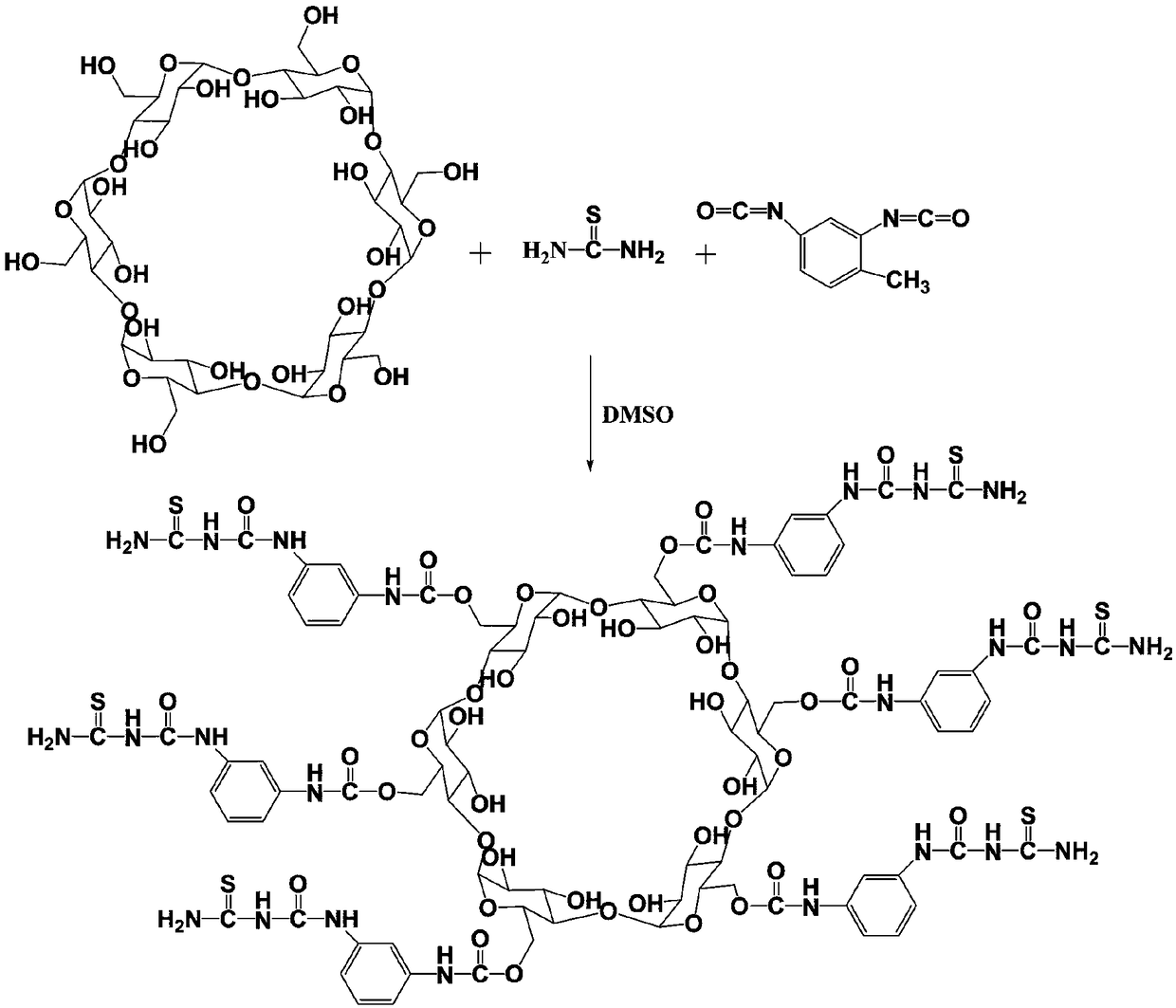

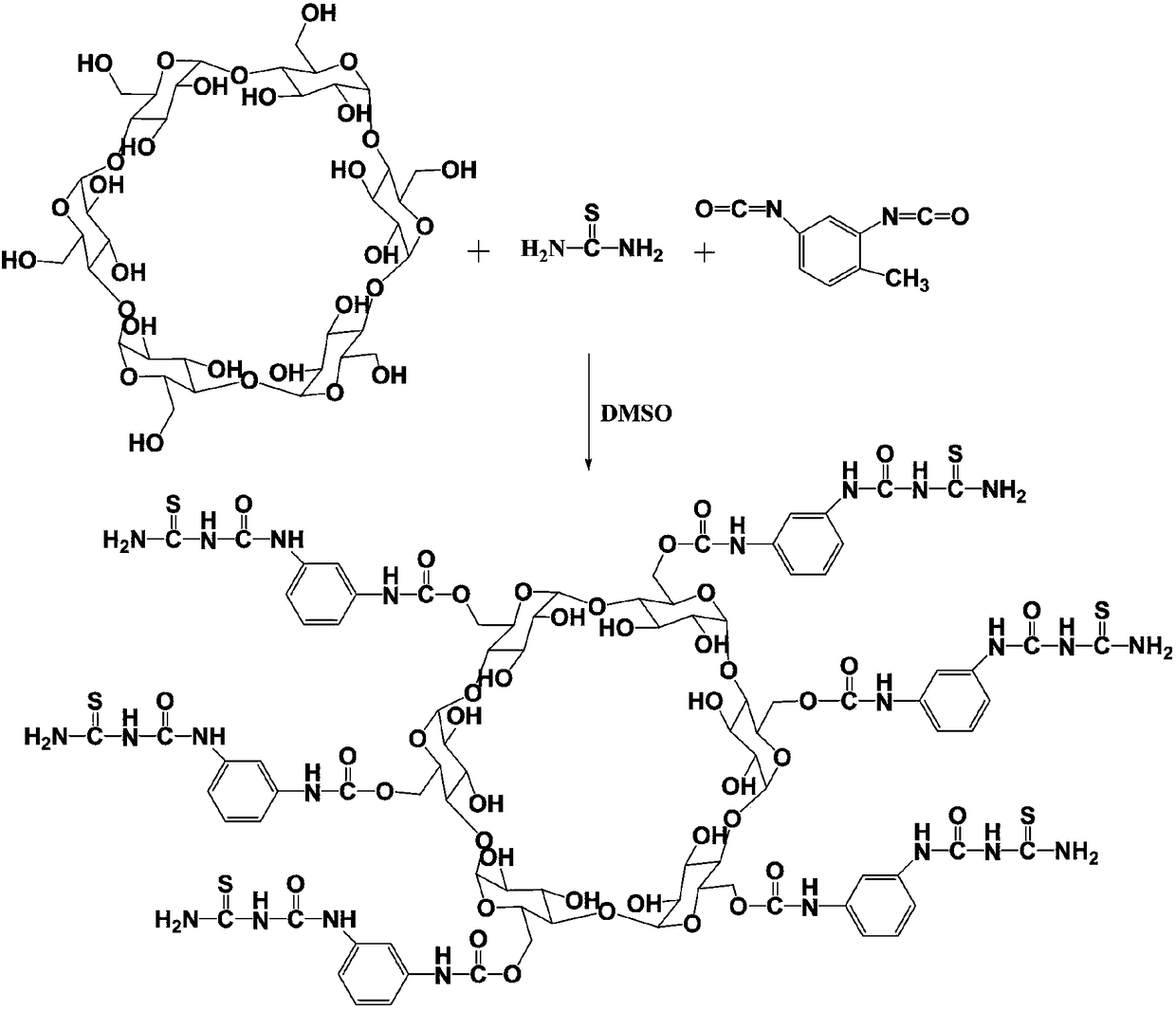

Method used

Image

Examples

Embodiment 1

[0031] The preparation process of the composite barrier powder is as follows:

[0032] Step 1: Add 1kg of starch to 2L of water to make a starch solution;

[0033] Step 2: Add 150g of sodium periodate to the starch solution, raise the temperature to 50°C and stir for 1 hour, then add 50mL of ethylene glycol to remove unreacted sodium periodate, then wash with ethanol and dry to obtain oxidized ring-opened starch;

[0034] Step 3: Add 900g of the oxidized ring-opened starch prepared in step 2 into 31.5L of water and mix evenly, add 10.8kg of fly ash into it, stir and mix thoroughly for 30min, then raise the temperature to 60°C, and add 2.7 L thiourea solution, wherein the thiourea solution is prepared by dissolving each gram of thiourea in 8 mL of water, stirring vigorously while adding dropwise, keeping 8-9 mL dropwise per minute, and reacting at a constant temperature for 3 hours after the dropwise addition, and then filtering and washing. The obtained product is ground to ...

Embodiment 2

[0040] The preparation process of the composite barrier powder is as follows:

[0041] Step 1: Add 1kg of starch to 2L of water to make a starch solution;

[0042] Step 2: Add 160g of sodium periodate to the starch solution, raise the temperature to 50°C and stir for 1 hour, then add 50mL of ethylene glycol to remove unreacted sodium periodate, then wash with ethanol and dry to obtain oxidized ring-opened starch;

[0043] Step 3: Add 900g of the oxidized ring-opened starch prepared in step 2 into 31.5L of water and mix evenly, add 11.7kg of fly ash to it, stir and mix thoroughly for 30min, then raise the temperature to 60°C, and add 2.7kg of L thiourea solution, wherein the thiourea solution is prepared by dissolving each gram of thiourea in 8 mL of water, stirring vigorously while adding dropwise, keeping 8-9 mL dropwise per minute, and reacting at a constant temperature for 3 hours after the dropwise addition, and then filtering and washing. The obtained product is ground ...

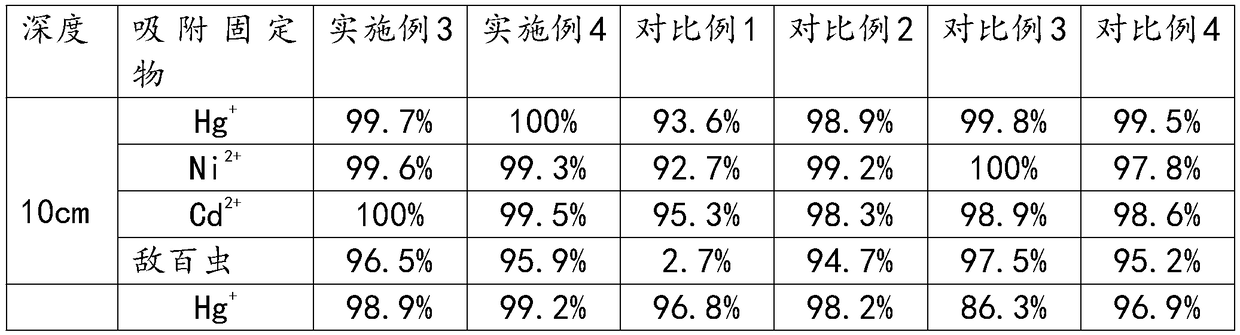

Embodiment 3

[0049] A method for soil restoration, specifically comprising the following processes:

[0050] In the first step, the soil in the polluted area is scooped up to a depth of 60 cm, and at the same time, a layer of composite barrier powder prepared in Example 1 is laid in the scooped-up soil pit, wherein the laying thickness is 1-1.2 cm;

[0051] In the second step, the scooped-up polluted soil is evenly mixed with the modified cyclodextrin prepared in Example 1 to obtain the pre-treated polluted soil. In the polluted soil with a total heavy metal content of 0.5-2%, every kilogram of heavy metal polluted soil is added Modified cyclodextrin 11-13g;

[0052] The third step is to pour the pretreated contaminated soil into the pit where the composite barrier powder is laid, and then spray a certain amount of leaching agent on the surface of the pretreated contaminated soil. Post-leaching reaction for 10 days, then spraying for the third time, leaching reaction after spraying for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com