A potassium conditioner for acidic soil in organic agriculture

A technology of acidic soil and conditioner, applied in soil conditioning materials, agriculture, organic fertilizers, etc., can solve the problems of environmental hazards, environmental hazards, being blown away by wind, etc., to prevent environmental pollution, save energy, and reduce leaching rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of potassium conditioner is:

[0035] After the low-grade attapulgite is pulverized, the above-prepared crop straw charcoal and the low-grade attapulgite are uniformly mixed in a weight ratio of 1:0.1-1:0.3 to obtain a potassium conditioner.

[0036] Among them, the low-grade attapulgite is naturally occurring or abandoned attapulgite tailings after physical beneficiation, and the attapulgite content is 20-50% by weight.

[0037] The particle size of the pulverized low-grade attapulgite is 0.1-8mm.

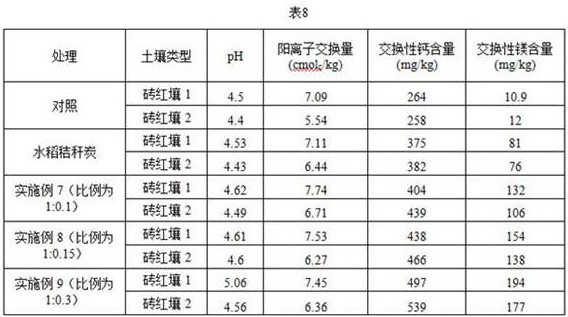

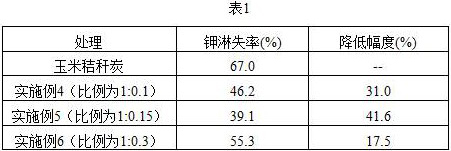

[0038] When in use, sprinkle the potassium conditioner on the surface of the acidic soil in organic agriculture at an application rate of 300-500kg / mu, and plow to fully mix the potassium conditioner with the field soil. It can regulate the potassium content in organic agricultural acidic soil: increase the potassium content of organic agricultural acidic soil; reduce the potassium leaching loss of organic agricultural acidic soil; it can also increase...

Embodiment 1

[0040] Example 1 Preparation of Peanut Straw Charcoal

[0041] Fill the whole plant of peanut stalks after natural air-drying (a small amount of root system on the peanut stalks does not need to be removed) into the carbonization furnace, step on it while loading, cover the furnace cover after filling, and insert a thermometer through the small hole in the center of the furnace cover The progress of the pyrolysis process can be controlled by changing the temperature. The peanut straw was ignited through the furnace door below the carbonization furnace, and the furnace door was closed after burning for 5 minutes, so that the peanut straw was pyrolyzed in the carbonization furnace by itself. During the pyrolysis process, the anaerobic environment and pyrolysis temperature of the carbonization furnace are maintained by controlling the air intake. In this embodiment, the pyrolysis temperature is controlled at 350° C., and the pyrolysis process is completed when no smoke is genera...

Embodiment 2

[0042] Example 2 Preparation of corn stalk charcoal

[0043] Use a guillotine to cut the naturally air-dried corn stalks into stalks of ≤20cm, fill the straws into the carbonization furnace, step on them while loading them, cover the furnace cover after filling, and insert them through the small hole in the center of the furnace cover A thermometer is used to control the progress of the pyrolysis process through temperature changes. The corn stalks were ignited through the furnace door below the carbonization furnace, and the furnace door was closed after burning for 5 minutes, so that the corn stalks were pyrolyzed in the carbonization furnace. During the pyrolysis process, the anaerobic environment and pyrolysis temperature of the carbonization furnace are maintained by controlling the air intake. In this embodiment, the pyrolysis temperature is controlled at 400° C., and the pyrolysis process is completed when no smoke is generated. After the pyrolysis is completed, all t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com