A microwave-assisted leaching method of selenium and arsenic in copper anode slime

A copper anode slime and microwave-assisted technology, applied in the field of hydrometallurgy, can solve the problems of low leaching rate of selenium and arsenic, difficult treatment of leaching solution, metal leaching dispersion, etc., achieve efficient and rapid leaching, overcome metal leaching dispersion, and fast leaching speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In this embodiment, the main components of copper anode slime contain Cu 11.2%, Se 3.6%, As 1.8%, Ni22.8% by weight percentage, and adding concentration to the copper anode slime after sieving is 70g / L sodium hydroxide Carry out pulping, control the weight concentration of the copper anode mud slurry at 25%, place it in a microwave reaction furnace after pulping, the microwave frequency is 3000MHz, and the microwave power is 100Wh per kilogram of slurry, and the material is discharged after leaching reaction under normal pressure for 5 minutes , and carry out solid-liquid separation to obtain leachate containing selenium and arsenic.

[0018] Among them, the leaching rate of selenium is 98%, and the leaching rate of arsenic is 97%.

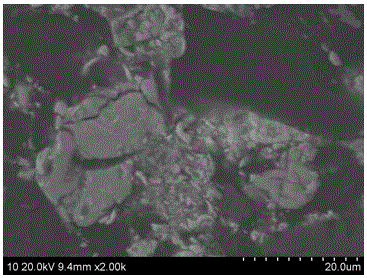

[0019] The copper anode slime after microwave-assisted leaching treatment is as follows figure 1 shown, from figure 1 It can be seen that there are obvious cracks on the surface of copper anode slime.

Embodiment 2

[0021] In this embodiment, the main components of copper anode slime contain Cu 12.4%, Se 3.9%, As 1.5%, Ni21.3% by weight percentage, and adding concentration to the copper anode slime after sieving is 130g / L sodium hydroxide Carry out pulping, control the weight concentration of the copper anode mud slurry at 35%, place it in a microwave reaction furnace after pulping, the microwave frequency is 1000MHz, and the microwave power is 200Wh per kilogram of slurry, and the material is discharged after leaching reaction under normal pressure for 12min , and carry out solid-liquid separation to obtain leachate containing selenium and arsenic.

[0022] Among them, the leaching rate of selenium is 99%, and the leaching rate of arsenic is 99%.

Embodiment 3

[0024] In this embodiment, the main components of copper anode slime contain Cu 11.9%, Se 4.6%, As 2.2%, Ni21.9% by weight percentage, and adding concentration to the copper anode slime after sieving is 100g / L sodium hydroxide Carry out pulping, control the weight concentration of the copper anode mud slurry at 30%, place it in a microwave reaction furnace after pulping, the microwave frequency is 500MHz, and the microwave power is 150Wh per kilogram of slurry, leaching and reacting under normal pressure for 8 minutes before discharging , and carry out solid-liquid separation to obtain leachate containing selenium and arsenic.

[0025] Among them, the leaching rate of selenium is 97%, and the leaching rate of arsenic is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com