Impeller investment casting process, impeller and centrifugal compressor

A technology of investment casting and impeller, which is applied in the field of impeller investment casting, impeller and centrifugal compressor, which can solve the problems of large fillet at the welding point, large dynamic balance of impeller, and poor dimensional accuracy of castings, etc., and achieve good tensile strength Strength and yield strength, improved energy efficiency of compressors, and high mold dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

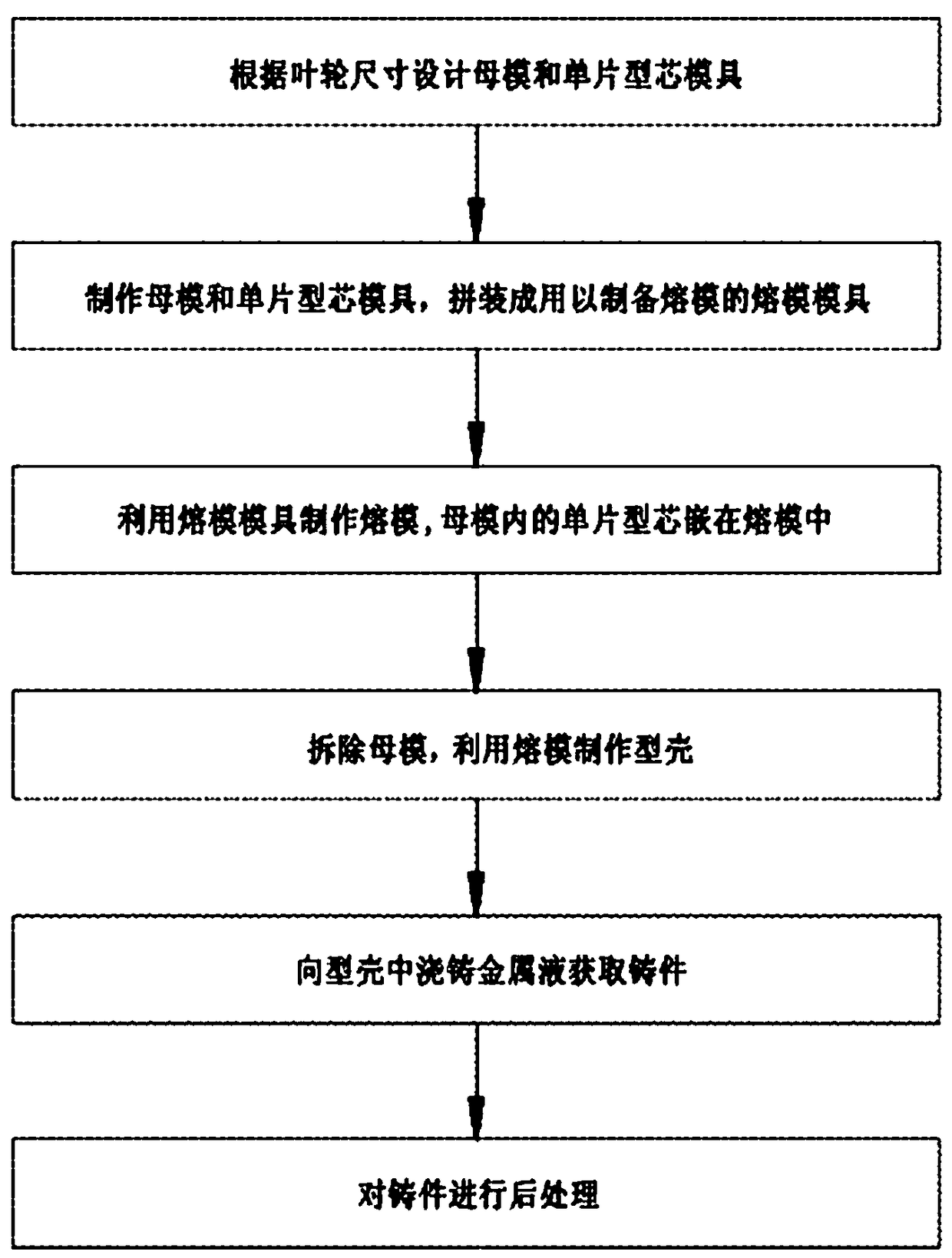

[0046] like figure 1 , 2 As shown, the impeller investment casting process proposed by the present invention includes steps 1 to 6 in a preferred embodiment, which will be described in detail below.

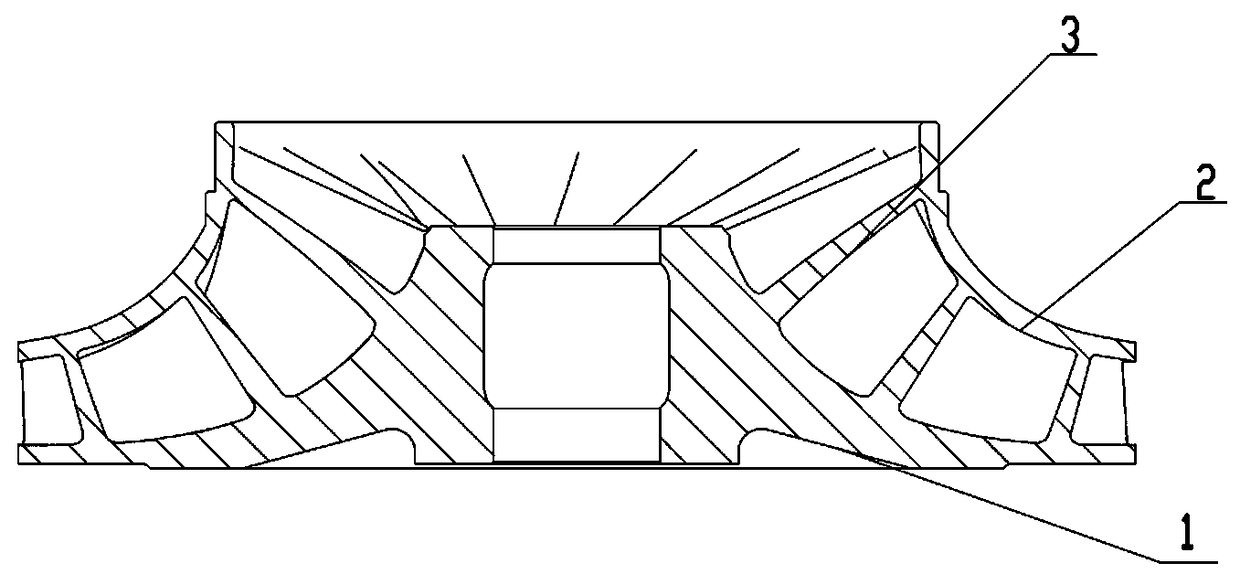

[0047] Step 1. Design the master mold and the single-piece core according to the size of the impeller. There are multiple single-piece cores assembled inside the master mold. The cavity between the master mold and the multiple single-piece cores is the investment cavity. The shape is the same as that of the impeller. In a preferred embodiment, the single-piece cores are in the same spiral shape as the blades 3 of the impeller, and the gap between two adjacent single-piece cores in the mother mold matches the shape of the blades 3 . From a structural point of view, multiple single-piece cores are assembled inside the mother mold to form a circular core mold group. The cavity between the top of the core mold group and the mother mold is in the shape of the wheel cover 2 of the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com