Intelligent preheating mechanism for steel rail thermit welding

An aluminothermic welding and aluminothermic welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of inability to accurately control the preheating temperature, poor adjustment of the flame of the preheating gun, high flame temperature or To improve the effect of rail preheating, ensure the quality of aluminothermic welding, and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

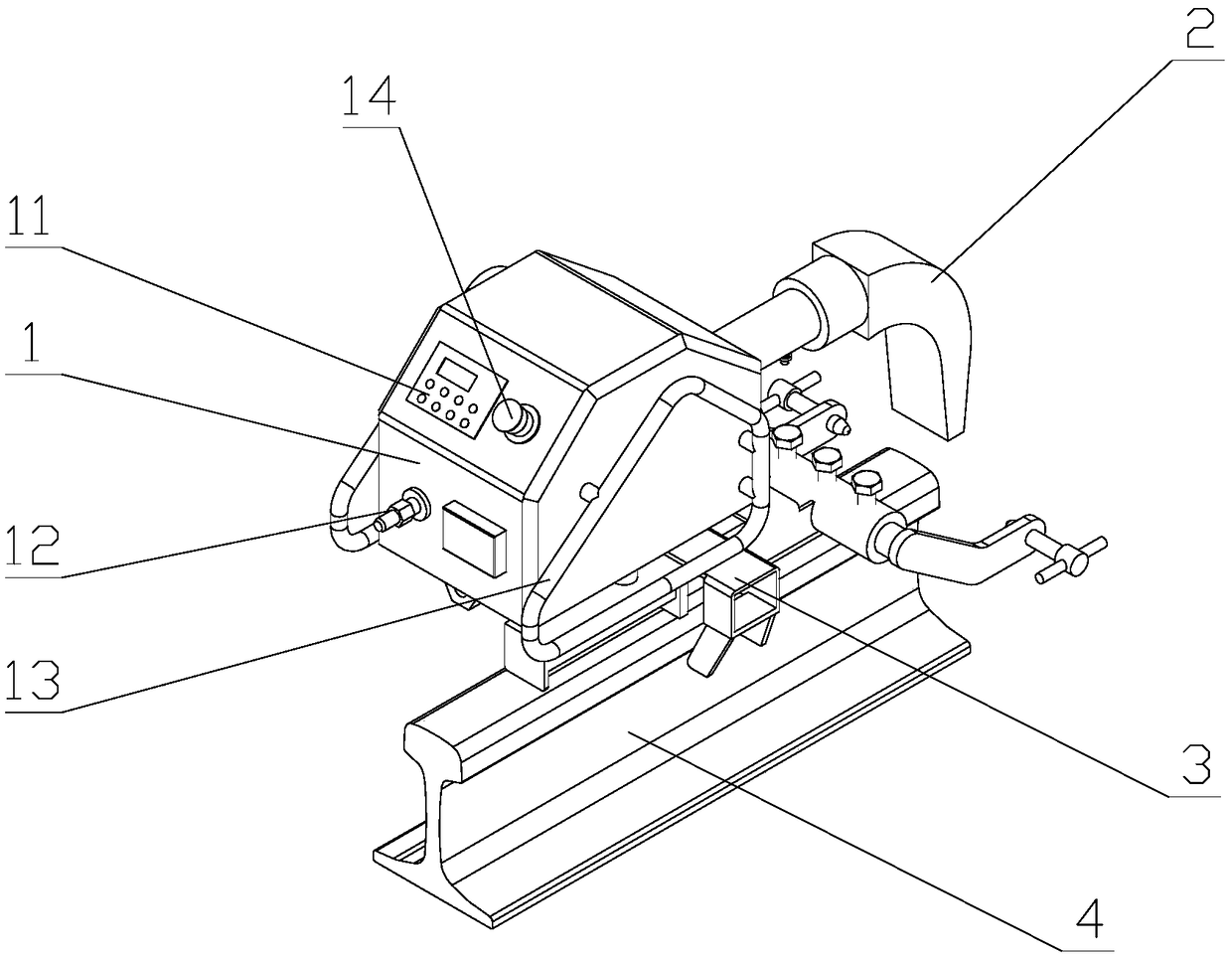

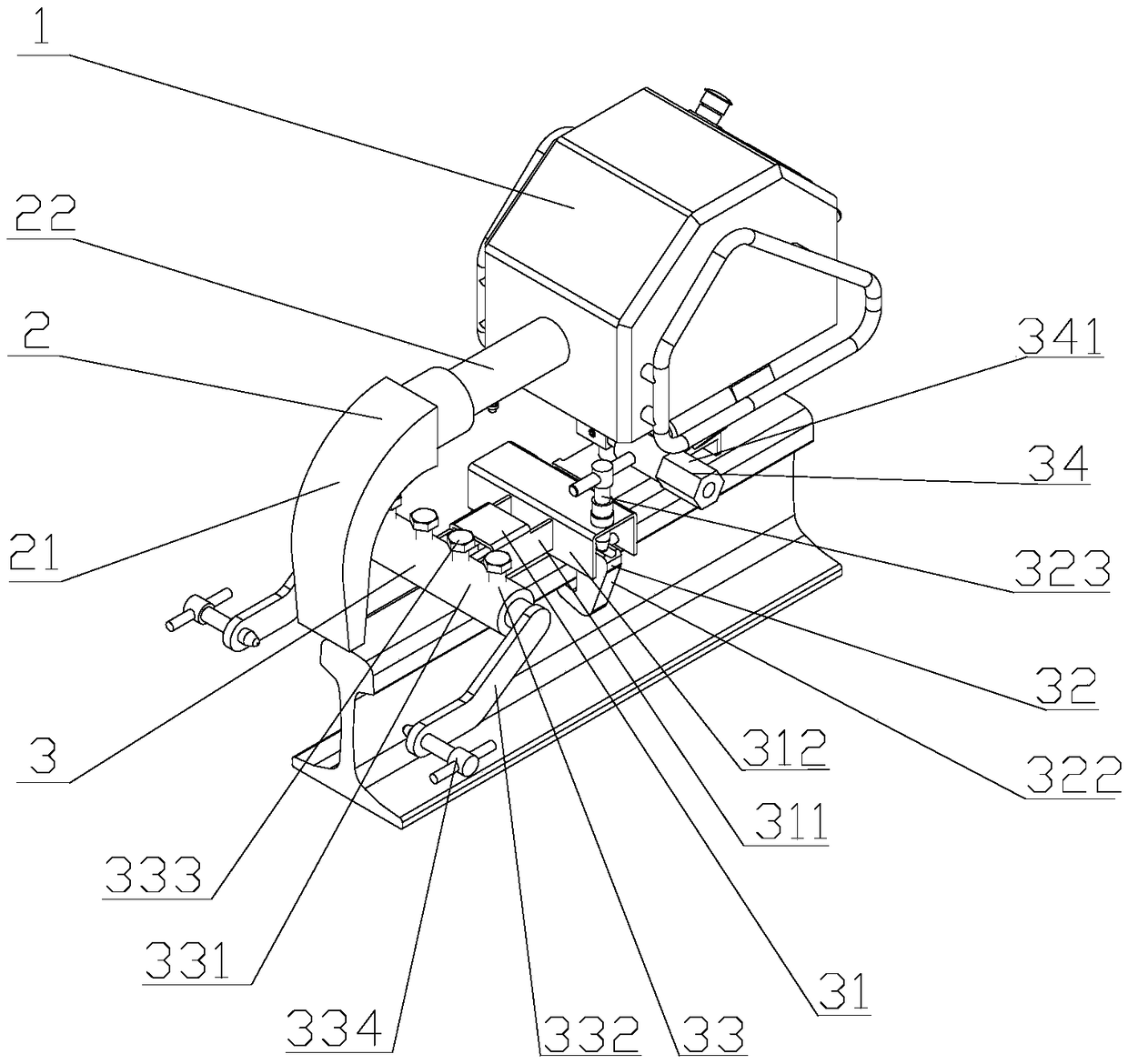

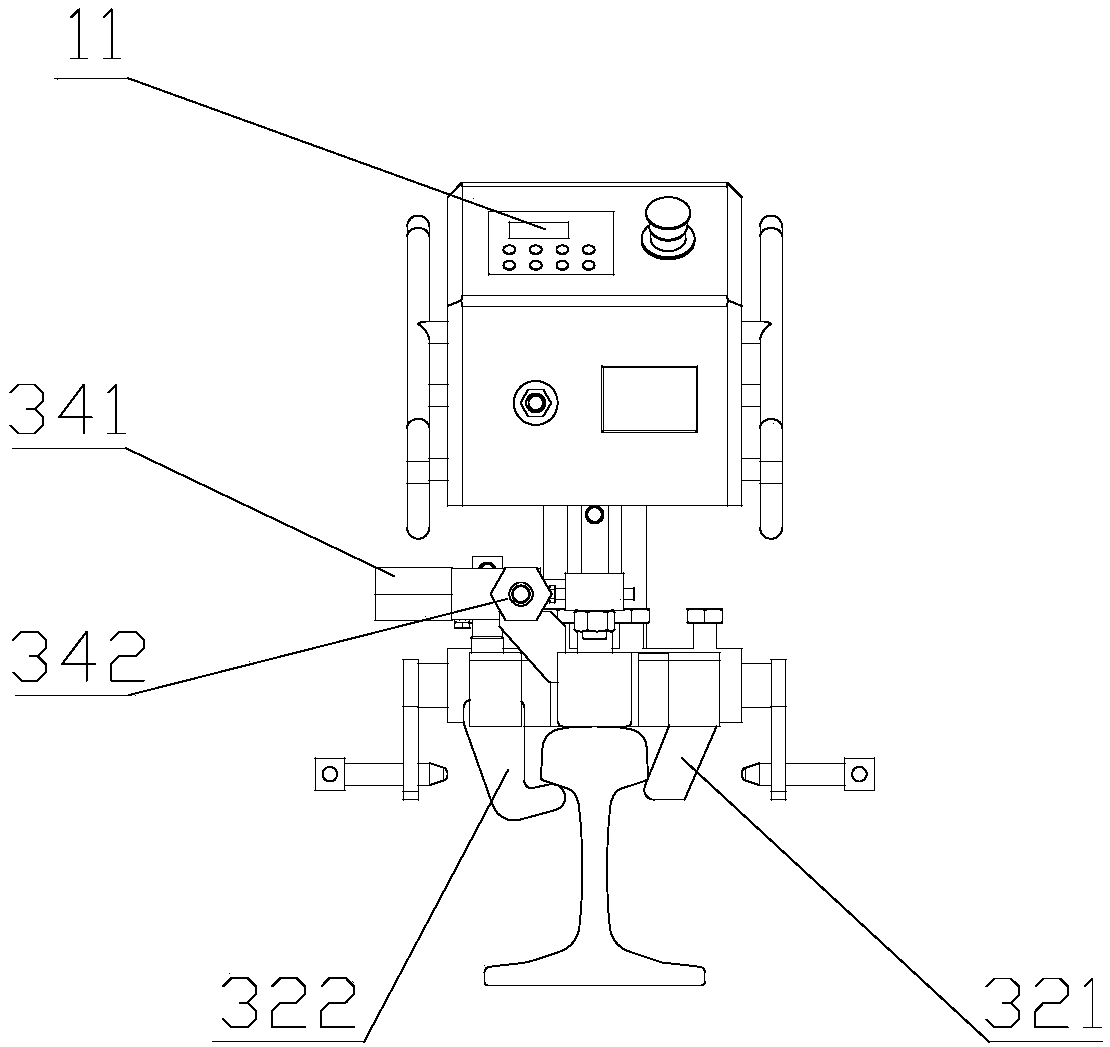

[0022] Please refer to Figure 1-Figure 3 , this embodiment is an intelligent preheating mechanism for rail aluminothermic welding, which includes a positioning and clamping unit 3 , an intelligent control system 1 arranged on the positioning and clamping unit 3 , and a combustion unit 2 connected to the intelligent control system 1 .

[0023] The intelligent control system 1 includes a burner (marked in the figure), a control unit 11 for controlling the burner, a gas pipe interface 12 communicating with the burner, a protective bracket 13, and a control unit for controlling the burner to start or stop. The start-stop button 14 of. The control unit 11 precisely controls the combustion time, gas flow, pressure and flame shape of the burner.

[0024] The combustion unit 2 includes an air intake pipe 22 communicated with the burner, and a combustion nozzle 21 communicated with the other end of the air intake pipe 22. The combustion nozzle 21 is a 90° bent square pipe, and the sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com