Smooth plywood single-layer veneer production line

A plywood and veneer technology, which is applied in the direction of plywood press, wooden veneer joint, veneer press, etc., can solve the problems of high-efficiency veneer, practicability needs to be improved, poor continuity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

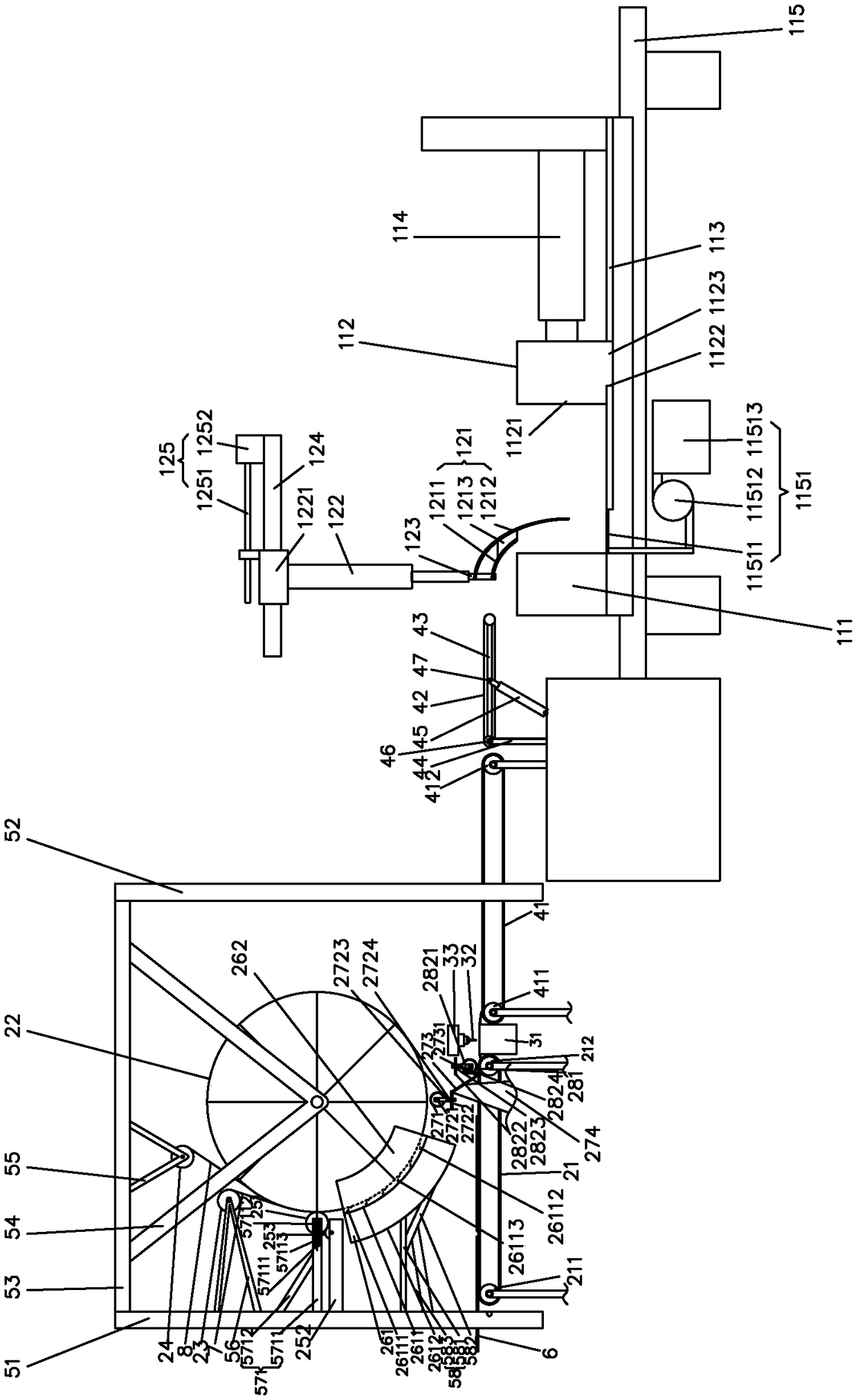

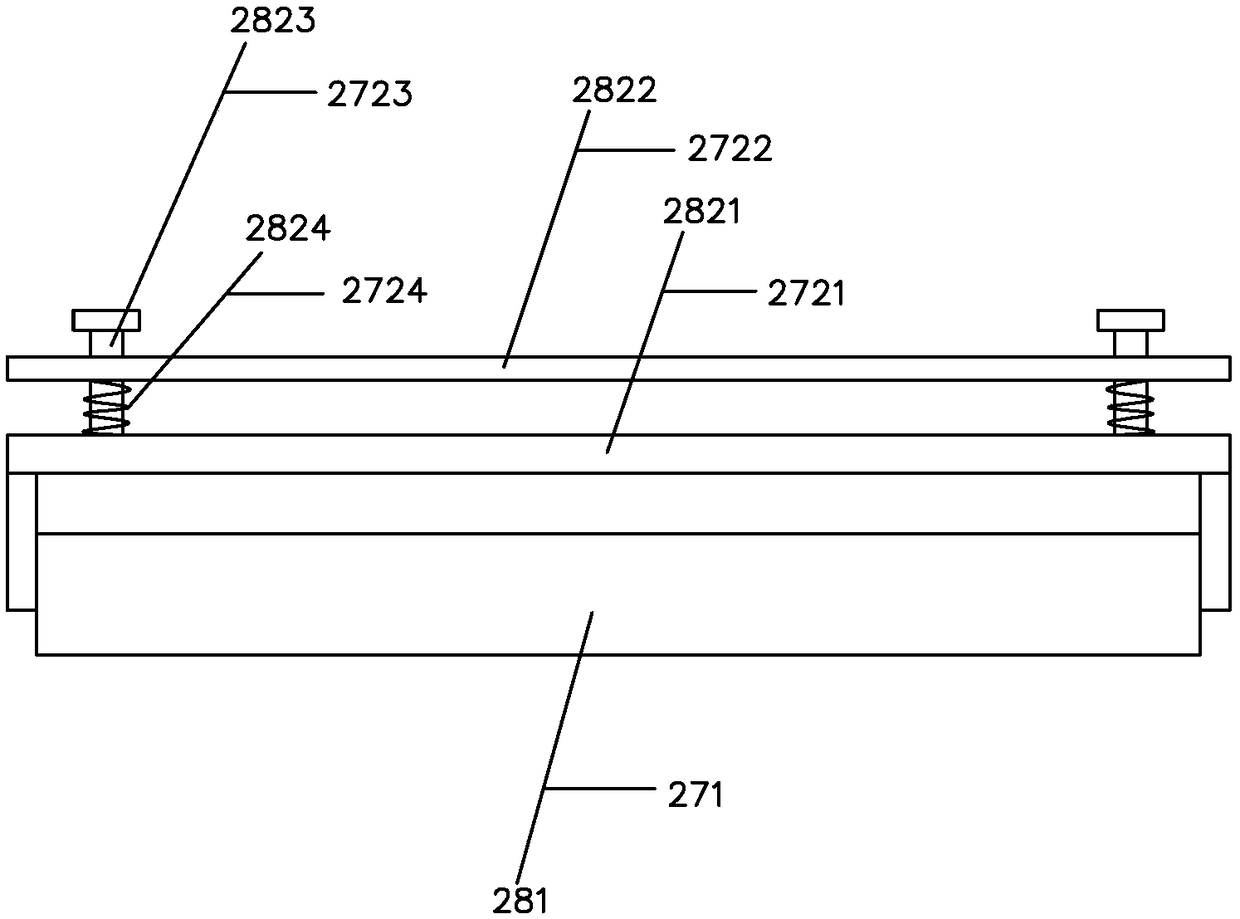

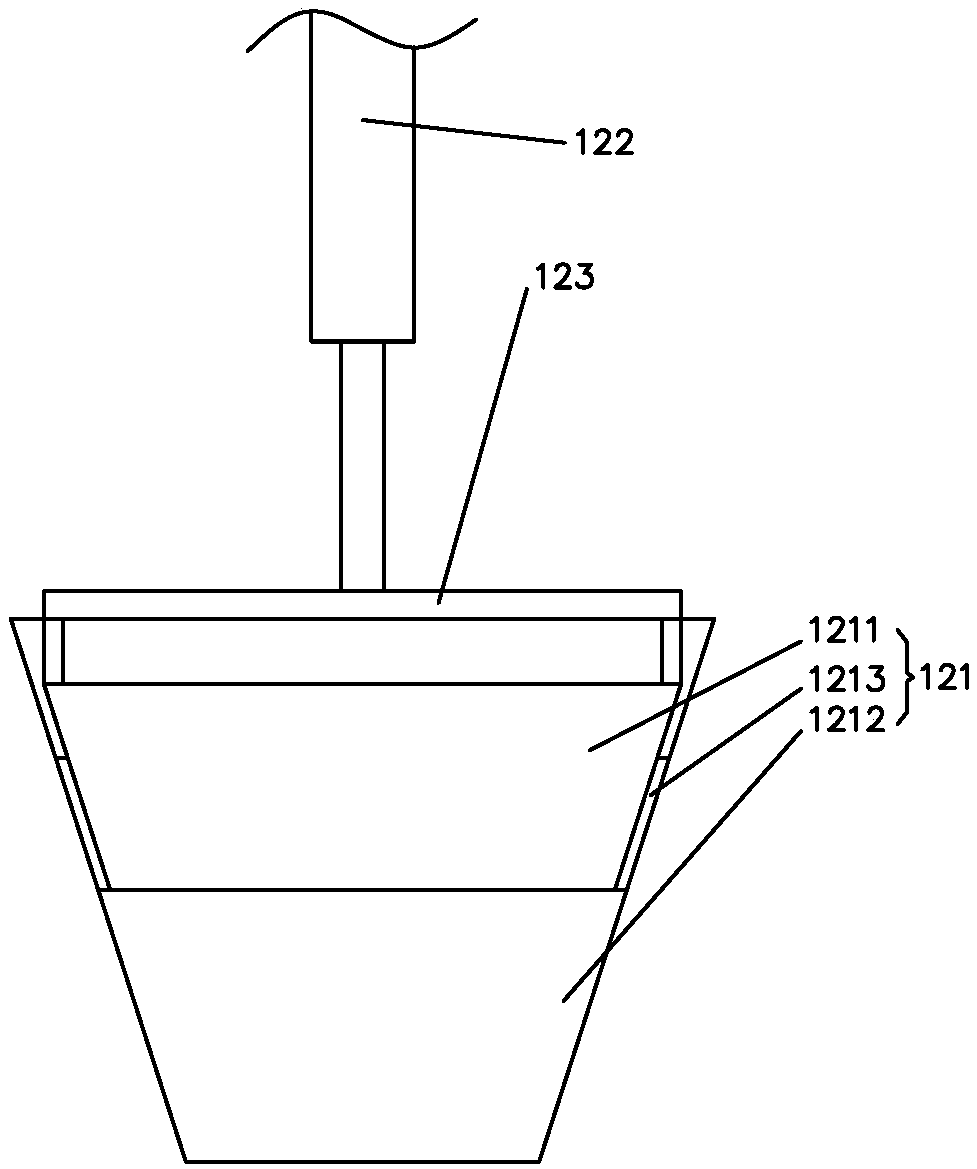

[0048] A smooth plywood single-layer veneer production line of the present invention, such as Figure 1-9 As shown, it includes a horizontal thermocompression forming device, which glues the veneer surface layer 8 on the formwork blank 6 to form a veneer production section of a continuous veneer formwork, and cuts the continuous veneer formwork to form a cutting production section of a veneer formwork block, And the veneer formwork blocks are delivered to the delivery production section of the horizontal thermocompression forming device one by one; preferably, the present invention also includes a frame that supports the veneer production section and the cutting production section; preferably, the present invention also includes a support for the horizontal The main controller for controlling the thermoforming device, veneer production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com