Structure for suppressing cavity resonance in automobile tire based on phononic crystal noise reduction theory

A phononic crystal, inner cavity technology, applied in vehicle parts, tire parts, transportation and packaging, etc., can solve the problems of dynamic imbalance and high cost, and achieve the effect of small additional weight and less damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

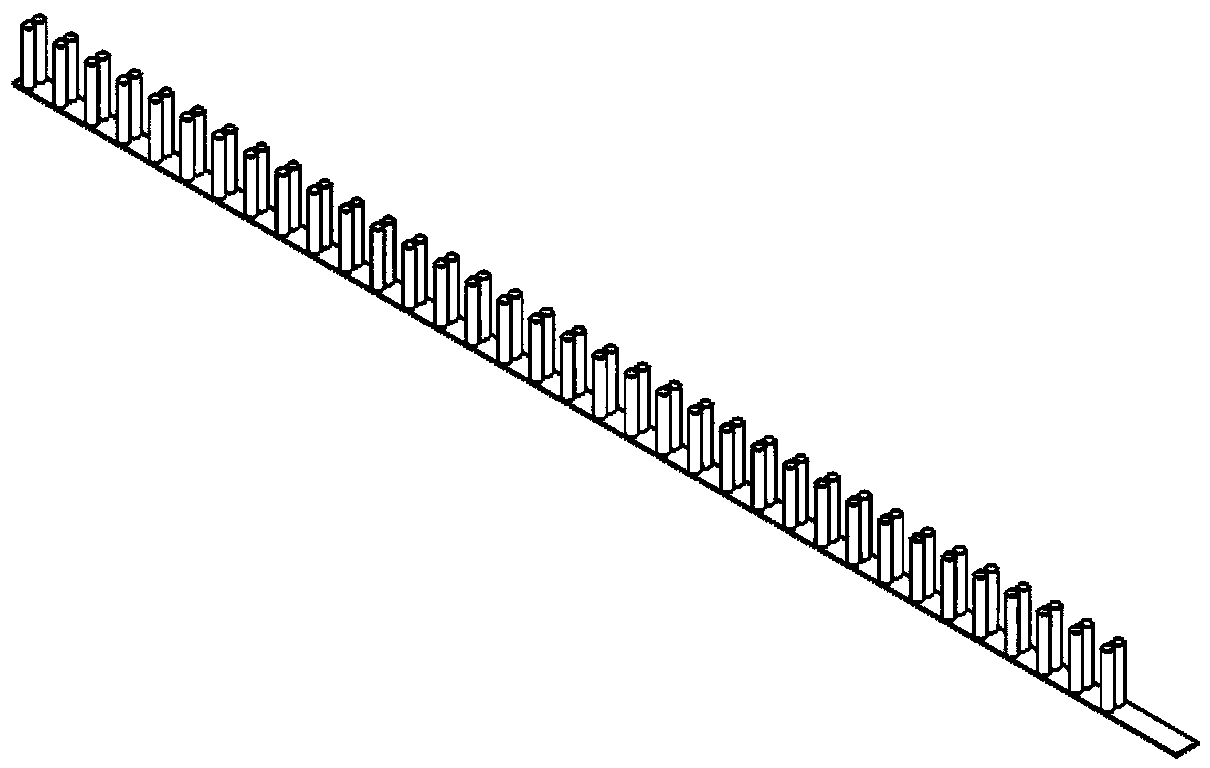

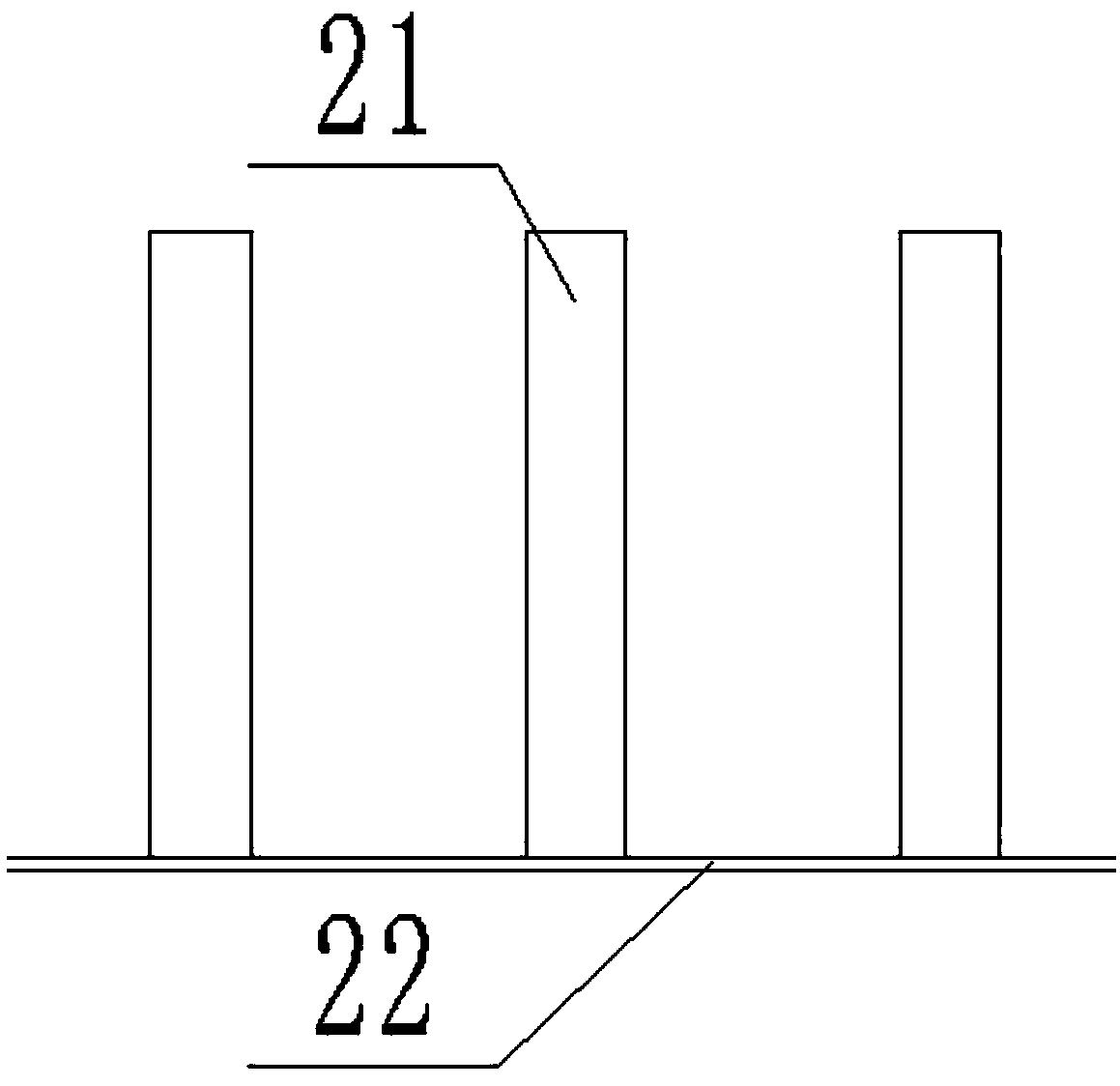

[0026] Implementation case 1: Based on the above design ideas, this case designs a phonon crystal structure in which the elastic cylinder is evenly distributed along the circumference. The material is silicone rubber. The baseband is 1100mm long, 31mm wide and 1mm thick. The cylinder has a diameter of 5mm and a height of 50mm. The number of cycles arranged along the width direction of the cylinder is 5 with a pitch of 1 mm, and the number of cycles arranged along the length direction of the tape is 35 with a pitch of 26 mm. Fix the phononic crystal structure in the deep groove of the rim with locks along the outer contour circumference of the deep groove of the rim, and surround the top of the phononic crystal structure with a plastic restraint belt that is equal in width or slightly wider than the phononic crystal structure. The elastic body cylinder is bent in the same direction and restrained under the restraint belt, and the restraint belt is connected with the lock firs...

Embodiment example 2

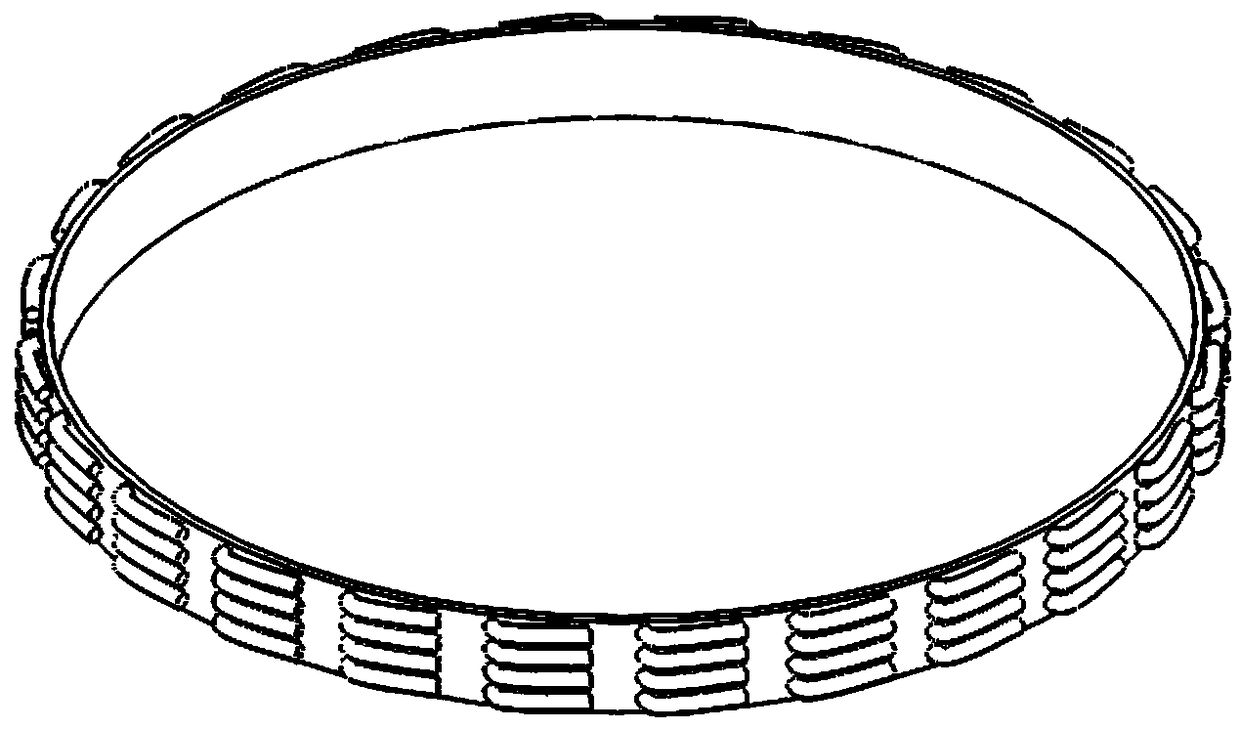

[0027] Implementation Case 2: Based on the above design ideas, this case designs a phonon crystal structure in which elastomer cylinders are distributed along the circumferential region, and all elastomer cylinders are symmetrical about the center of the wheel, as shown in Image 6 shown. The material is polyurethane. The baseband is 1200mm long, 22mm wide and 2mm thick. The cylinder has a diameter of 2mm and a height of 40mm. The number of cylinders arranged along the width direction is 5, the interval is 2mm, the number of periods arranged in each group of cylinders along the strip length direction is 10, the interval is 5mm, and 4 groups of cylinders are evenly distributed along the strip length direction. Fix the phononic crystal structure in the deep groove of the rim with locks along the outer contour circumference of the deep groove of the rim, and surround the top of the phononic crystal structure with a plastic restraint belt that is equal in width or slightly wider...

Embodiment example 3

[0028]Implementation Case 3: Based on the above design ideas, this case designs a phonon crystal structure in which elastomer cylinders are distributed along the circumferential area, and all elastomer cylinders are symmetrical about the center of the wheel, and there are elastomers of different diameters and lengths in the phonon crystal structure cylindrical, such as Figure 8 , 9 shown. The material is EPDM rubber. The baseband is 1000mm long, 22mm wide, and 0.5mm thick. Arrange cylinders of two geometries. The diameter of the thin cylinder is 2mm, the height is 40mm, and the number of periods arranged along the width direction is 5, and the interval is 2mm. The diameter of the thick cylinder is 4mm, the height is 26mm, and the number of periods arranged along the width direction is 4, and the interval is 1mm. The number of cycles arranged in each group of cylinders along the length of the belt is 10, and the thick and thin cylinders are arranged alternately with a spa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com