Iron oxide powder dechlorinating device and control method thereof

A technology of iron oxide powder and controller, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, temperature control, etc., can solve the problems of no later dechlorination process, unstable dechlorination effect, difficult to meet, etc., and achieve compact structure , stable and reliable operation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

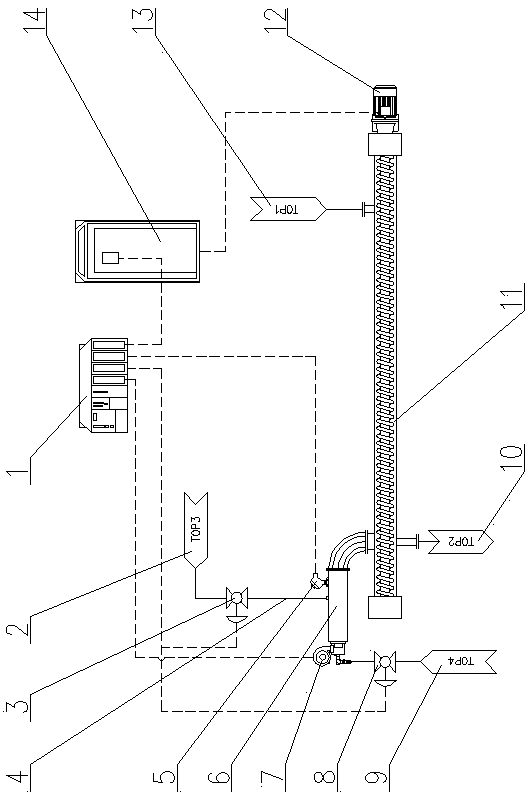

[0021] see figure 1 , an iron oxide powder dechlorination device is composed of a controller 1, a frequency converter 14, a screw conveyor 11 and a high-temperature vaporization desalinated water mechanism, and the screw conveyor 11 is connected to the iron oxide powder inlet 13 and the iron oxide powder outlet 10. On the conveying pipeline of iron oxide powder, the driving motor 12 of the screw conveyor 11 is connected to the frequency converter 14, and the driving motor 12 is a variable frequency motor, and the driving motor 12 is controlled by the frequency converter 14 to realize the adjustment of the conveying speed and weight of the iron oxide powder .

[0022] The high-temperature vaporization desalinated water mechanism is arranged at the tail of the screw conveyor 11, and is composed of desalinated water input pipeline 4, burner heater 6, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com