Method for drying sludge by utilizing residual heat of tunnel kiln

A technology of drying sludge and tunnel kiln, which is applied in the direction of dehydration/drying/concentrated sludge treatment, which can solve the problems of difficulty in increasing the amount of sludge and sludge drying, and achieve high automation and low energy consumption , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

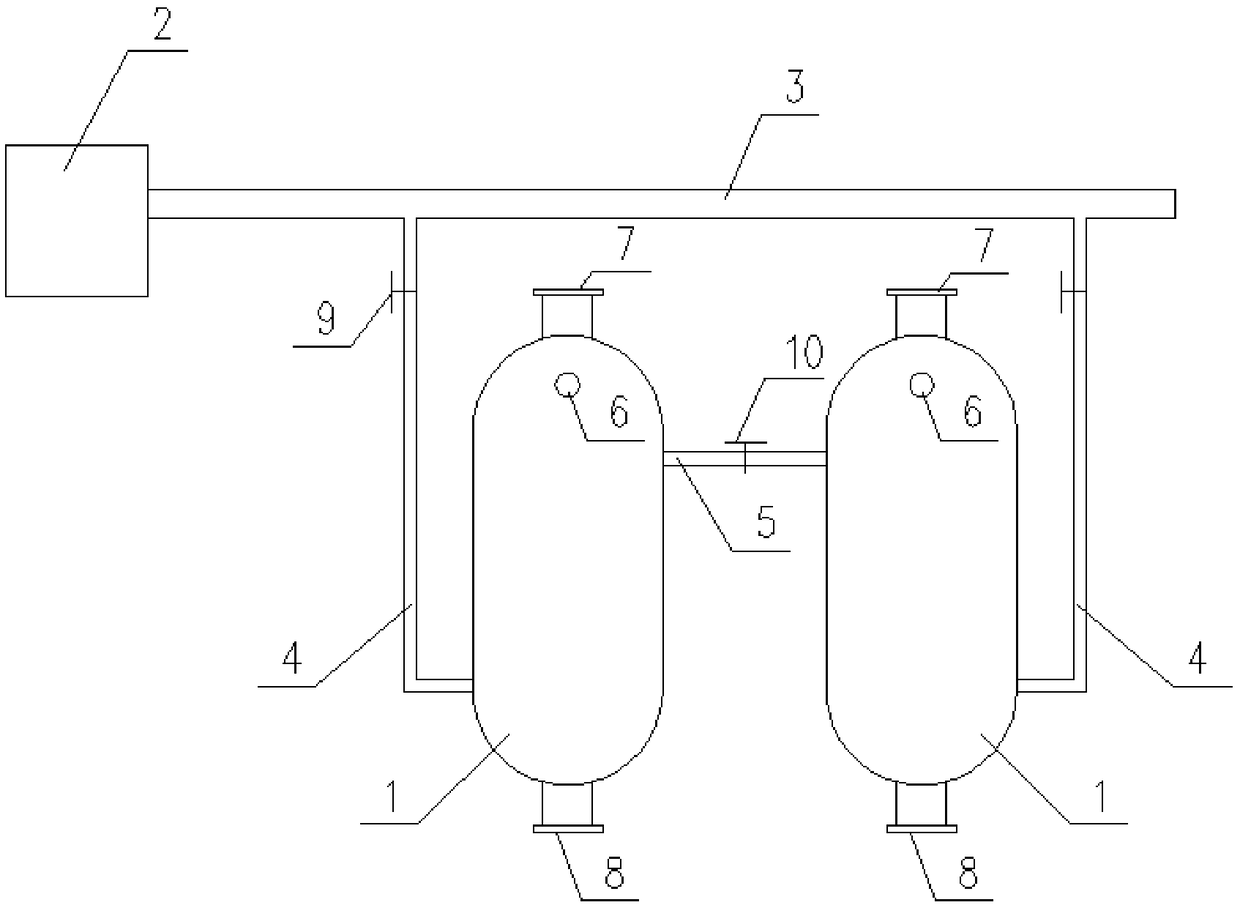

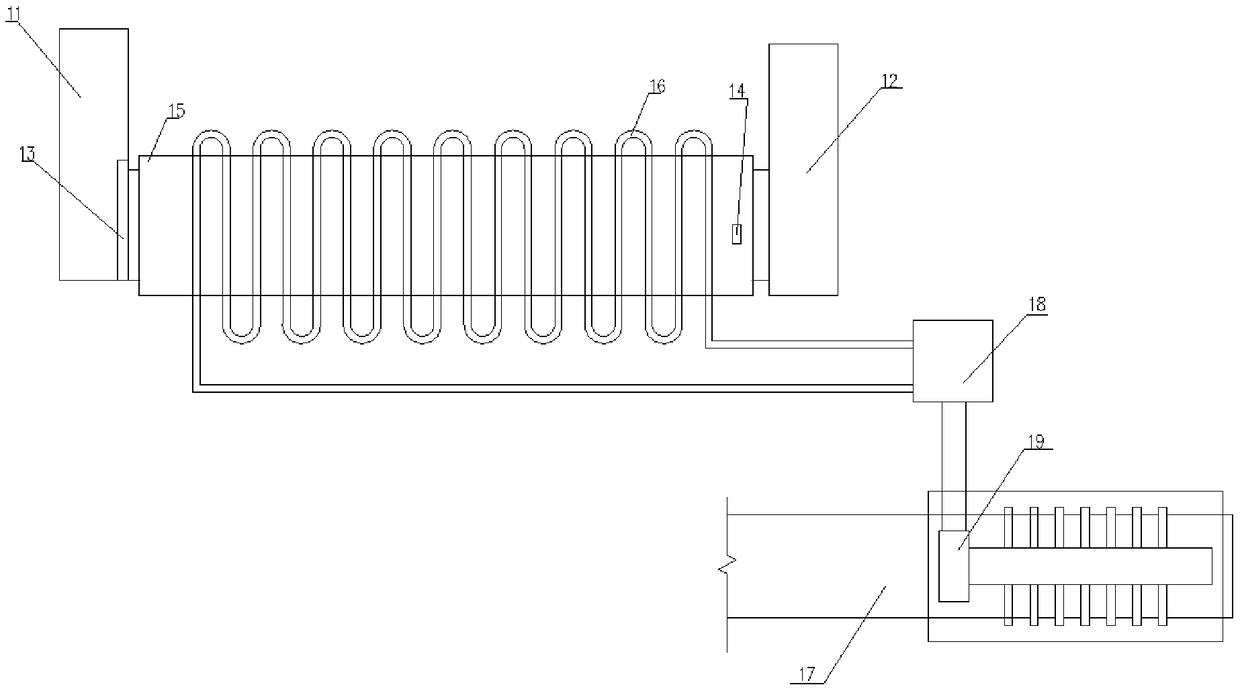

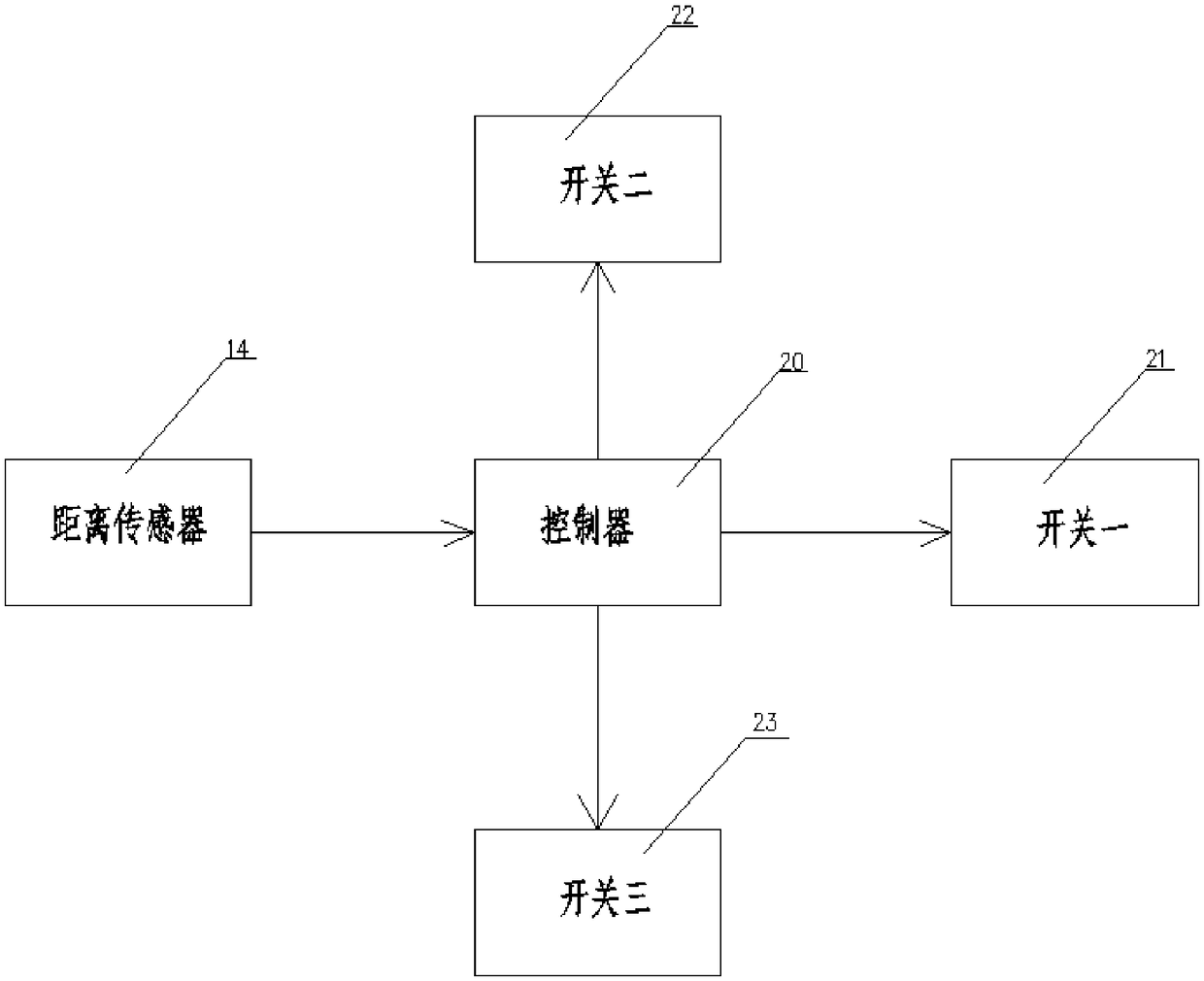

[0040] In this embodiment, the method for drying sludge by using the residual heat of a tunnel kiln comprises the following steps:

[0041] Step 1. Steam wall breaking: Send the sludge with a water content of 80%wt into the sludge steam wall breaking system, fill it with a steam pressure of 0.5MPa, and complete the wall breaking after a holding time of 20 hours, and discharge the sludge; The steam drawn from the tunnel kiln can be used to save energy;

[0042] Step 2, flocculation: send the sludge discharged after the wall breaking in step 1 into the flocculation tank, add an inorganic flocculant, and after mechanical stirring, complete the flocculation after standing still; the addition amount of the inorganic flocculant is after the wall breaking 1.5% of the discharged sludge mass; the inorganic flocculant is polyaluminum chloride;

[0043] Step 3. Sedimentation: send the sludge flocculated in step 2 into the sedimentation tank for sedimentation, and remove the liquid in th...

Embodiment 2

[0057] In this embodiment, the method for drying sludge by using the residual heat of a tunnel kiln comprises the following steps:

[0058] Step 1. Steam wall breaking: The sludge with a water content of not less than 80wt% is broken through the sludge steam wall breaking system, and the steam pressure is not lower than 0.4MPa. After 20 hours of pressure holding time, the wall breaking is completed and the sludge is discharged;

[0059] Step 2, flocculation: send the sludge discharged after the wall breaking in step 1 into the flocculation tank, add an inorganic flocculant, and after mechanical stirring, complete the flocculation after standing still; the addition amount of the inorganic flocculant is after the wall breaking 1% of the mass of the sludge discharged;

[0060] Step 3. Sedimentation: send the sludge flocculated in step 2 into the sedimentation tank for sedimentation, and remove the liquid in the upper layer to obtain sedimentation sludge;

[0061] Step 4, deodori...

Embodiment 3

[0067] In this embodiment, the method for drying sludge by using the residual heat of a tunnel kiln comprises the following steps:

[0068] Step 1. Steam wall breaking: The sludge with a water content of not less than 80wt% is broken through the sludge steam wall breaking system, and the steam pressure is not lower than 0.4MPa. After 20 hours of pressure holding time, the wall breaking is completed and the sludge is discharged;

[0069] Step 2, flocculation: send the sludge discharged after the wall breaking in step 1 into the flocculation tank, add an inorganic flocculant, and after mechanical stirring, complete the flocculation after standing still; the addition amount of the inorganic flocculant is after the wall breaking 2% of the mass of the sludge discharged;

[0070] Step 3. Sedimentation: send the sludge flocculated in step 2 into the sedimentation tank for sedimentation, and remove the liquid in the upper layer to obtain sedimentation sludge;

[0071] Step 4, deodori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com