Black pearlescent pigment and preparation method and application thereof

A pearlescent pigment, black technology, applied in the direction of pigment preparation, inorganic pigment processing, chemical instruments and methods, etc., can solve the problems of limited application range of black pearlescent pigments, insufficient blackness and brightness, poor temperature resistance, etc., to increase reflection and Refraction, high blackness and brightness, easy to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] According to one aspect of the present invention, a kind of preparation method of black pearlescent pigment, described method comprises the following steps:

[0058] First, add water to the pigment base material to make a slurry, and then use the method of hydrolytic coating in sequence according to the layered sequence of the black pearlescent pigment from the inside to the outside. 1, a silicon-doped cobalt oxide layer, a second ferric oxide layer and a second cobalt oxide layer are coated on the pigment substrate, and then an outer protective layer is optionally coated to obtain a black pearlescent pigment.

[0059] The preparation method of the black pearlescent pigment provided by the present invention, the preparation method uses the method of hydrolytic coating in sequence according to the layered sequence of the black pearlescent pigment from the inside to the outside, the indium oxide layer, the first ferric oxide layer, the first oxide The cobalt layer, the si...

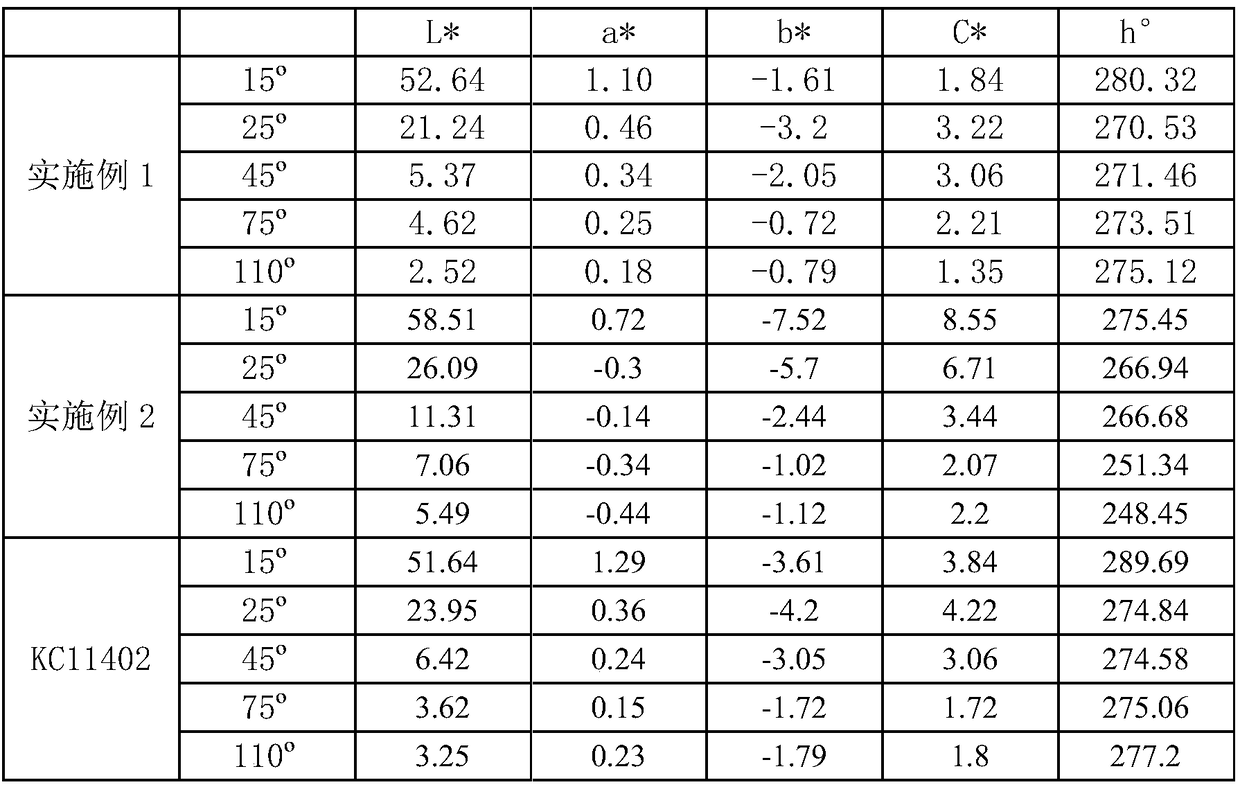

Embodiment 1

[0078] Under stirring conditions, add 100 g of fluorphlogopite mica with a particle size range of 5-45 μm (average particle size is 27 μm) into 2 L of soft water, and heat to 80 ° C, and adjust the pH value to 3.0 with 1:1 hydrochloric acid, Then slowly meter in 200ml 5% indium trichloride solution, adopt 30% sodium hydroxide solution to carry out constant pH value constant,

[0079] After the addition, continue to slowly meter in 900ml of 10% ferric chloride solution. During this period, use 30% sodium hydroxide solution to keep the pH constant, and then increase the pH to 8.0, then slowly meter in 200ml of 5% Cobalt chloride solution, simultaneously with 30% sodium hydroxide control and keep PH=8.0 constant;

[0080] Continue to stir for half an hour after the addition, use 1:1 hydrochloric acid to reduce the pH value to 3.0, continue to slowly add 900ml of 10% ferric chloride solution, and use 30% sodium hydroxide solution to keep the pH value unchanged.

[0081] Continue ...

Embodiment 2

[0085] Under stirring conditions, add 100 g of fluorphlogopite mica with a particle size range of 5-45 μm (average particle size is 27 μm) into 2 L of soft water, and heat to 80 ° C, and adjust the pH value to 3.0 with 1:1 hydrochloric acid, Then slowly meter in 200ml 5% indium trichloride solution, adopt 30% sodium hydroxide solution to carry out constant pH value constant,

[0086] After the addition, continue to slowly meter in 900ml of 10% ferric chloride solution. During this period, use 30% sodium hydroxide solution to keep the pH constant, and then increase the pH to 8.0, then slowly meter in 200ml of 5% Cobalt chloride solution, while using 30% sodium hydroxide to control and keep pH=8.0 constant.

[0087] Continue stirring for half an hour after the addition, at this pH value, slowly meter in 500 ml of 20% sodium silicate solution while controlling and keeping the pH at 8.0 with 5% cobalt chloride solution.

[0088] Continue to stir for half an hour after the additio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com