Preparation method of stable nanocrystal with NaYF4:Yb3+/Er3+@BiOCL (bismuth oxychloride) core-shell structure

A core-shell structure and nanocrystal technology is applied in the field of preparation of NaYF4:Yb3+/Er3+@BiOCl composite materials, which can solve problems such as low photoelectric conversion efficiency, and achieve the effects of low cost of raw materials, simple equipment and convenient operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

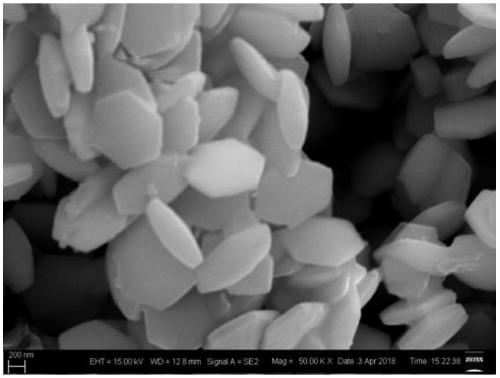

[0018] Specific embodiment one: the stable NaYF of this embodiment 4 :Yb 3+ / Er 3+ The preparation method of @BiOCl core-shell structure nanocrystals is carried out according to the following steps:

[0019] 1. BiCl 3 Add to ethylene glycol, heat to 60~65°C and stir evenly to get BiCl 3 solution;

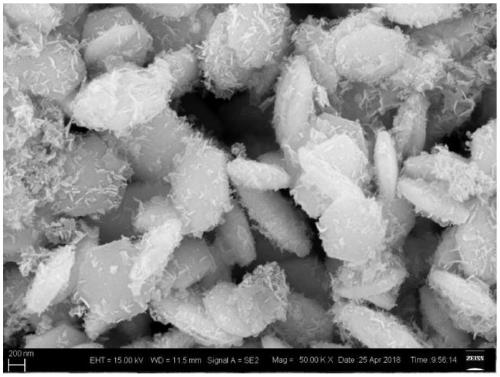

[0020] Second, the NaYF 4 :Yb 3+ / Er 3+ Add to BiCl 3 solution, stir evenly, cool to room temperature, and adjust the pH of the solution to 8~9, reheat to 60~65°C and stir for 0.5~1h, then cool and stand still, remove the supernatant, add ethanol and stir evenly, Put it in an oven and dry it at 40-60°C to get BiOCl-coated NaYF 4 :Yb 3 + / Er 3+ Nanocrystalline;

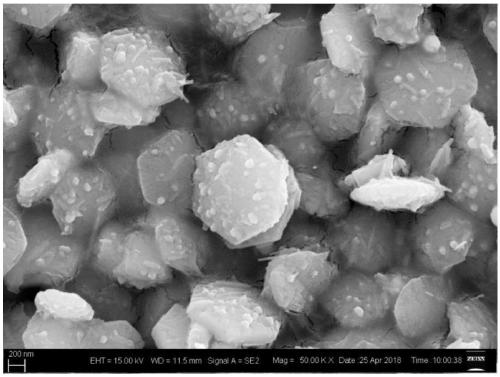

[0021] 3. The NaYF coated with BiOCl prepared in step 2 4 :Yb 3+ / Er 3+ Nanocrystals are placed in an alumina crucible, and then the alumina crucible is placed in a muffle furnace, heated to 200-300°C for 1-3 hours in an air atmosphere, and then cooled naturally to obtain a stable NaYF 4 :Yb 3+ / Er 3+ @BiO...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the BiCl in step one 3 The ratio of the amount of the substance to the volume of ethylene glycol is 1 mmol: (15-20) mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that NaYF in step two 4 :Yb 3+ / Er 3+ with BiCl 3The molar ratio is 1:(0.1~0.2). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow density | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com