Wall body heat-preservation mortar

A technology for thermal insulation mortar and wall, applied in covering/lining, building, building structure, etc., can solve the problems of high-altitude operation, high maintenance technical requirements, and difficult to clean dirt, etc., to reduce water leakage. , The effect of increasing the strength of the wall and reducing the damage of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

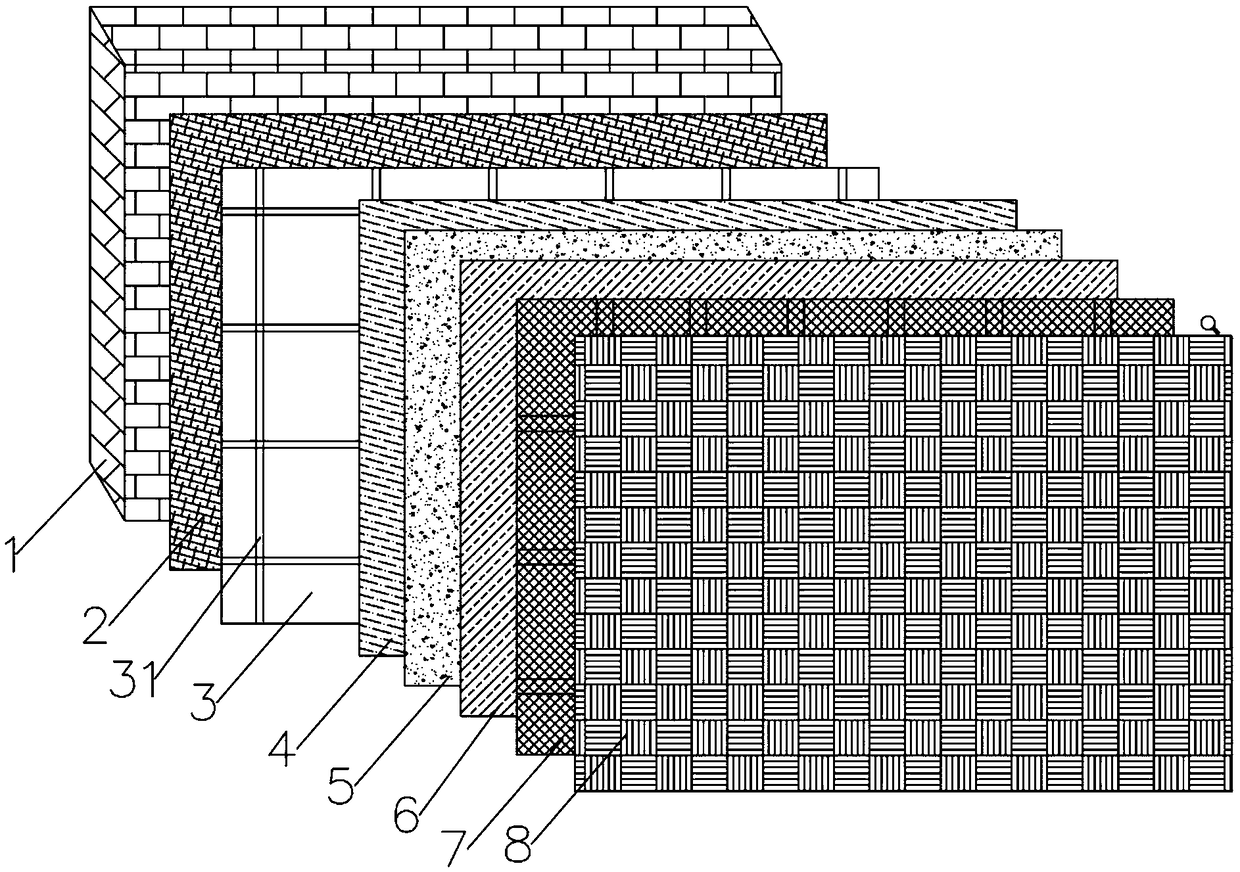

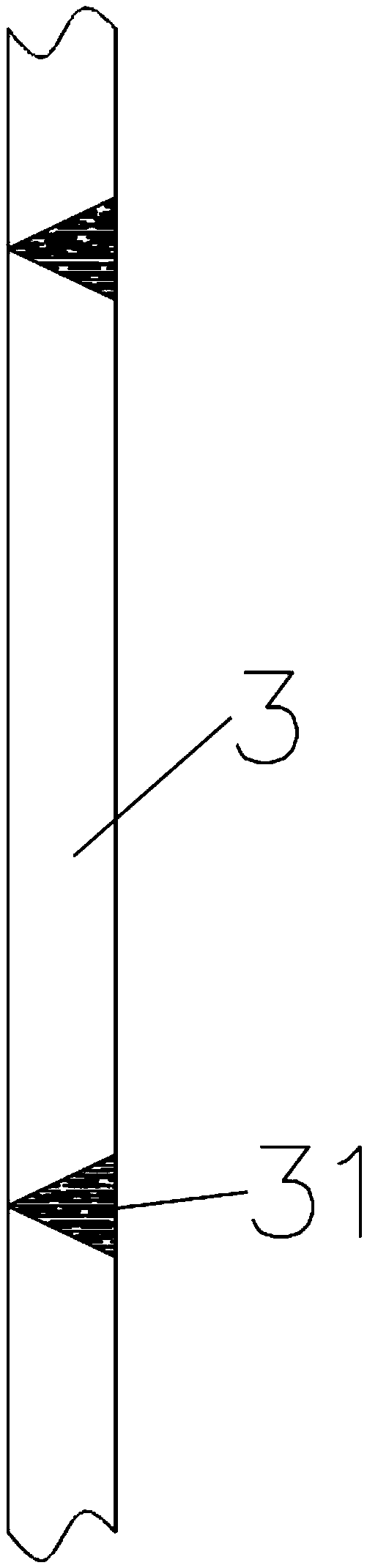

[0030] Such as figure 1 As shown, Embodiment 1 provides a wall thermal insulation mortar, including a wall 1, and the outer wall surface of the wall is sequentially provided with a leveling mortar layer 2, a waterproof mortar layer 3, an interface mortar layer 4, and a thermal insulation mortar layer from the inside to the outside. 5. Crack-resistant mortar layer 6 and facing layer 8. By setting a waterproof mortar layer to reduce the occurrence of water leakage from the external insulation wall.

[0031] In this embodiment, the finish layer 8 is a finish paint, and an alkali-resistant glass fiber mesh cloth 7 is pressed into the crack-resistant mortar layer 6. The surface of the crack-resistant mortar layer 6 is coated with flexible water-resistant putty, and the finish paint is coated on a flexible water-resistant Putty surface. The thickness of the anti-crack mortar layer 6 is 3mm-5mm. In this embodiment, the thickness of the anti-crack mortar layer 6 is specifically set ...

Embodiment 2

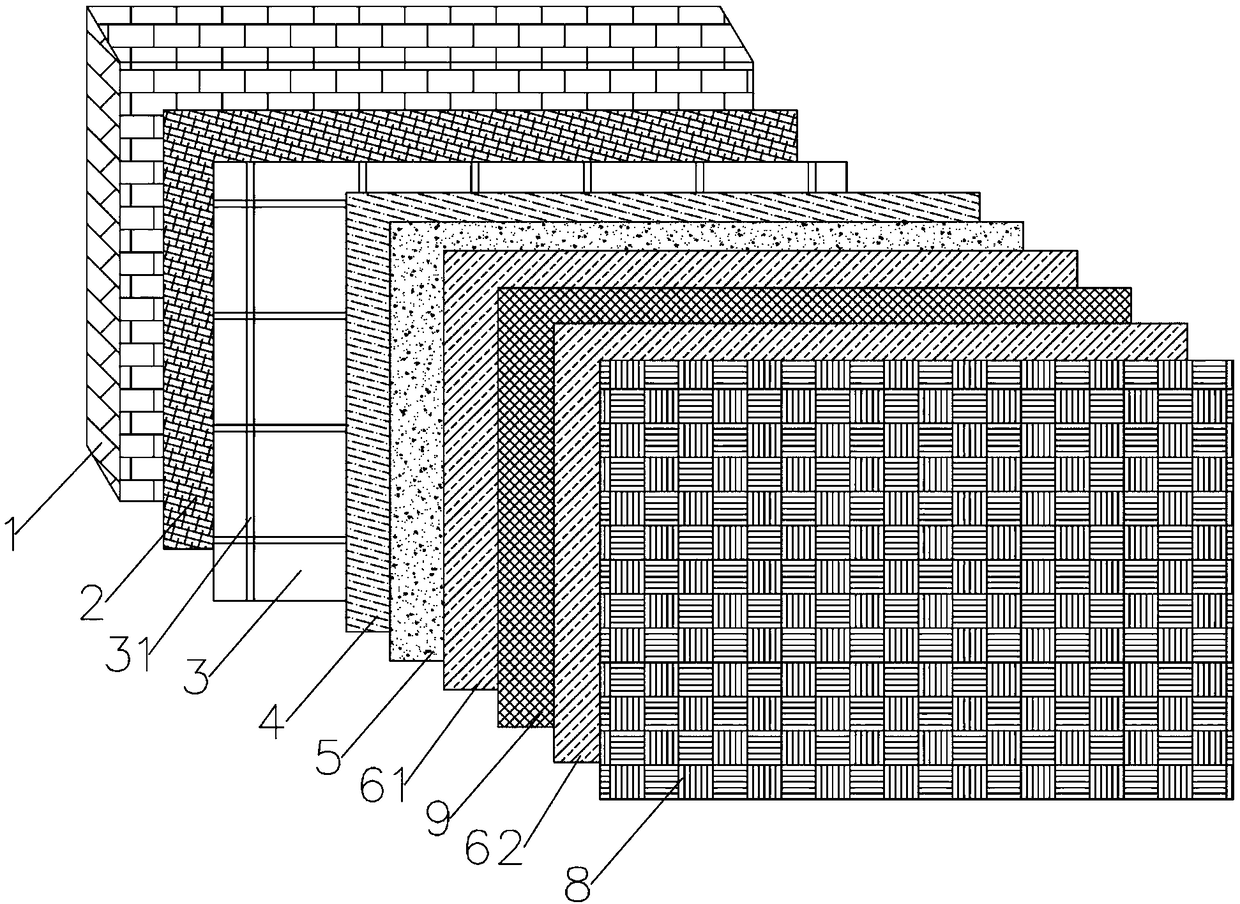

[0036] Such as image 3 As shown, Embodiment 2 provides a wall thermal insulation mortar. The difference from Embodiment 1 is that in Embodiment 2, the facing layer 8 is a face brick, and the anti-cracking mortar layer includes the first anti-cracking mortar layer arranged from the inside to the outside. The cracking mortar layer 61 and the second anti-cracking mortar layer 62, the first anti-cracking mortar layer 61 and the second cracking-resistant mortar layer 62 are provided with hot-dip galvanized welded mesh 9, the hot-dip galvanized welded mesh 9 is anchored by anchor bolts, and the facing brick It is bonded to the second anti-cracking mortar layer 62 through the brick bonding mortar, and a brick pointing material is provided between the bricks. Hot-dip galvanized steel wire mesh can play the role of moisture resistance and heat preservation, and can significantly reduce the damage to the wall caused by thermal expansion and contraction. On the other hand, the toughness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com