Wireless laser matrix monitoring system and method for surface area deformation observation

A wireless laser and monitoring system technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of continuous observation of ground deformation in mining subsidence areas, avoid work complexity, increase accuracy, and avoid installation difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

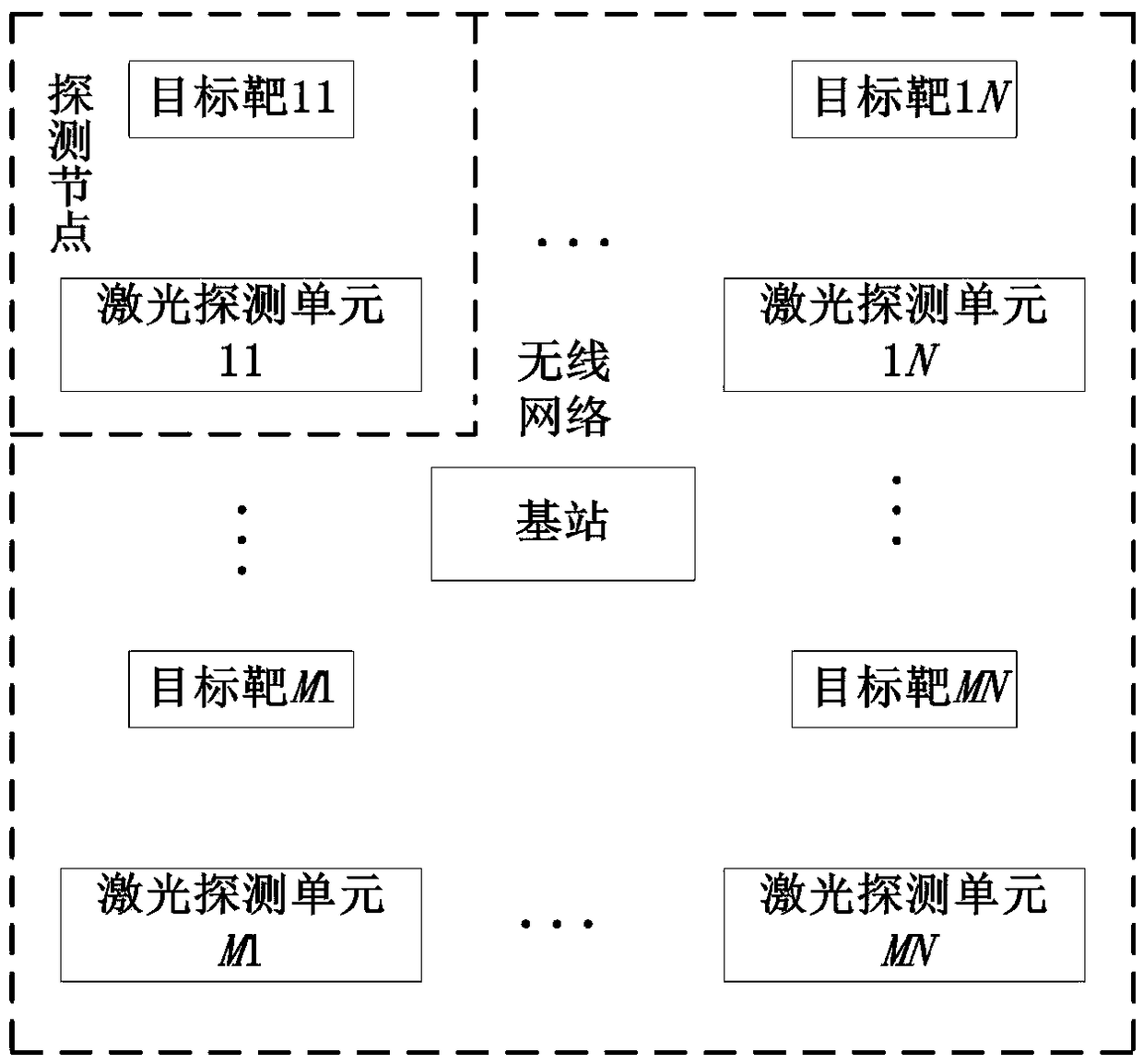

[0063] A specific embodiment of the present invention discloses a wireless laser matrix monitoring system for surface deformation observation, such as figure 1 As shown, the wireless laser matrix monitoring system includes an M×N field displacement detection array composed of M×N laser detection units, a base station, and the like. Among them, the number of M and N is determined according to the size of the area to be monitored and the layout requirements. Two-way data transmission is performed between the field displacement detection array and the base station through a wireless network.

[0064] The on-site displacement detection array is arranged in the surface area to be monitored, and the layout method can be uniformly arranged to monitor the surface deformation such as mining subsidence, landslides, cracks, etc. that may exist in the surface area to be monitored.

[0065] Each laser detection unit is equipped with a corresponding independent target, the target is set at...

Embodiment 2

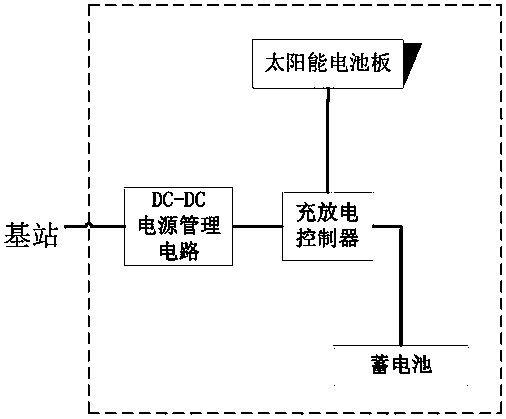

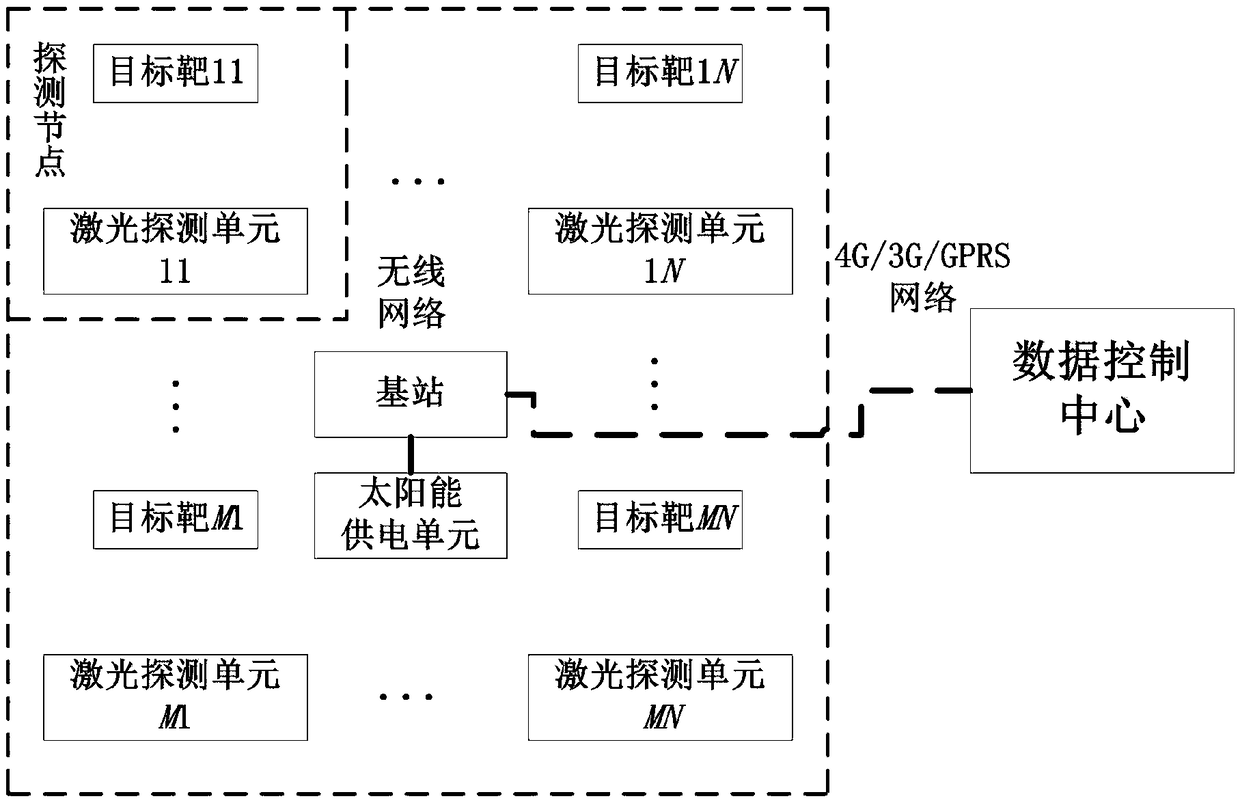

[0072] Optimized on the basis of Example 1, the wireless laser matrix monitoring system for surface deformation observation also includes a solar power supply unit and a data control center, such as figure 2 shown.

[0073] The output end of the solar power supply unit is connected with the power supply end of the base station to provide power for the operation of the base station. The on-site displacement detection array is equipped with a replaceable power supply, which is regularly replaced by professional technicians, and does not use a solar power supply unit for power supply.

[0074] The data control center further analyzes the processing results of all base stations in different surface areas to be monitored, and displays them, which is helpful to find the first or most serious position of the surface area deformation. The data control center includes a computer and supports 4G / 3G / GPRS communication. Correspondingly, the remote data transmission of the base station a...

Embodiment 3

[0095] A specific embodiment of the present invention discloses a method of using the wireless laser matrix monitoring system described in Embodiment 2 to observe the deformation of the surface area, such as Figure 8 shown, including the following steps:

[0096] S1. On-site displacement detection arrays are arranged in the surface area to be monitored. The distance between each laser detection unit should be less than 500m, and the deformation position between the laser detection unit and the target target spans the surface area, and there is no obstacle between the two; wireless data transmission The vertical height between the first antenna of the module and the ground is not less than 1m. The total number of detection nodes can be arranged according to the horizontal and vertical coordinates is 2 to 126.

[0097] S2. Arrange the base station in the surface area to be monitored. The distance between the base station and each laser detection unit should be less than 1km. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com