Method for accurately measuring thickness of multilayer micro-nano thin film on curved surface

A technology of precise measurement and film thickness, applied in the field of precise measurement of film thickness on cylindrical surface of cylindrical industrial transmission parts, scanning electron beam-focusing ion beam dual-beam system, and accurate measurement of micro-nano film thickness on curved surfaces, which can solve the problem of test accuracy It can achieve the effect of high measurement accuracy, simple and controllable process steps, and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] The scanning electron beam-focused ion beam dual-beam system model that can be used in the present invention is LYRA 3XMH produced by Czech TESCAN company, which is a conventional system of this type of equipment.

[0032] Put the workpiece into the sample chamber of the focused ion beam-scanning electron beam dual-beam system, and use the electron beam imaging unit to find the measurement point where the film thickness needs to be measured (such as figure 1 , inside the circle at the end of the cylindrical transmission).

[0033] According to the guidance of the dual-beam system, adjust the measurement point to the cooperative working point of the electron beam and the focused ion beam, and prepare the gas deposition system.

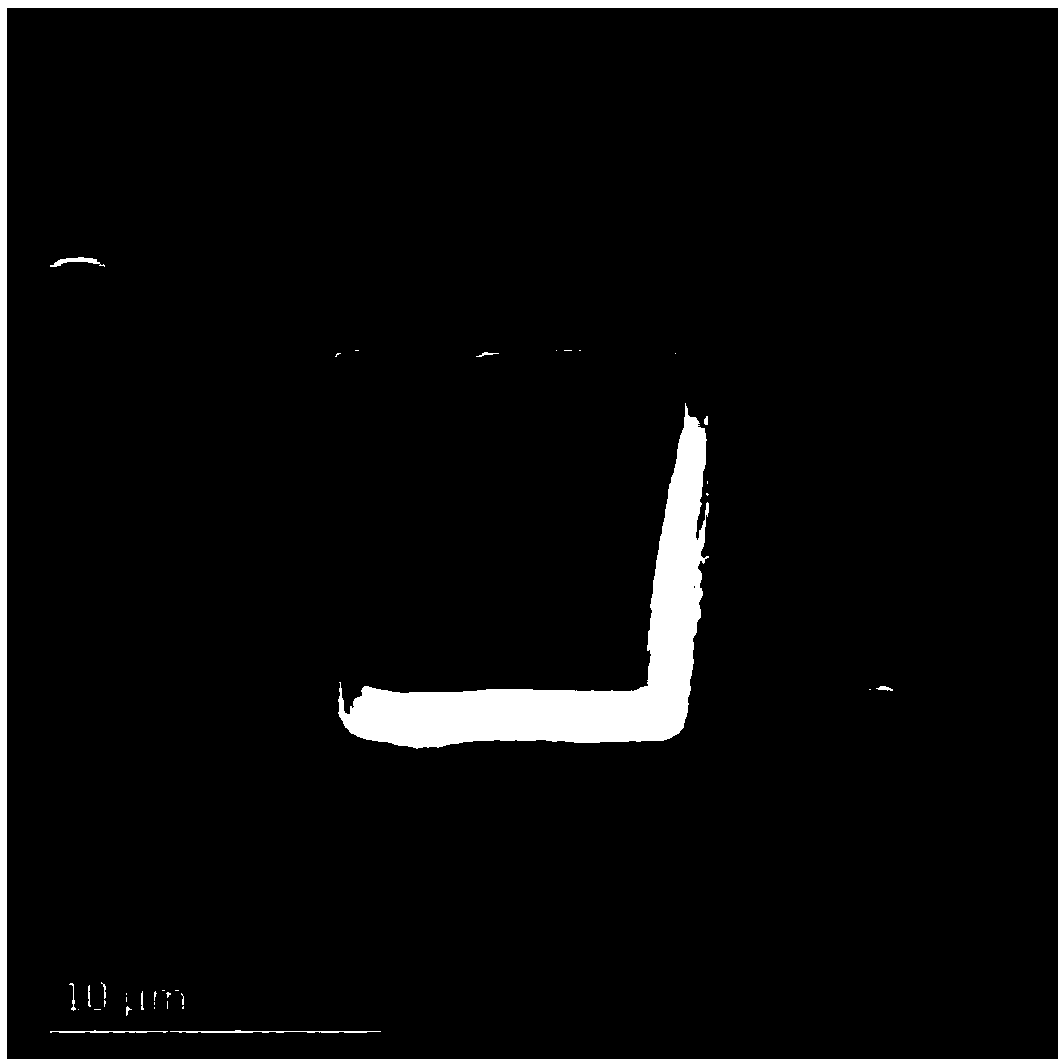

[0034] First, a layer of SiO with a length and width of 10 μm × 1 μm was pre-deposited at the measurement p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com