Measurement device and measurement method for residue carrying capability of mud

A measurement device and mud technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of unclear effect of slag-carrying capacity, no slag-carrying capacity of mud, etc., and achieve good geological adaptability, simple structure and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

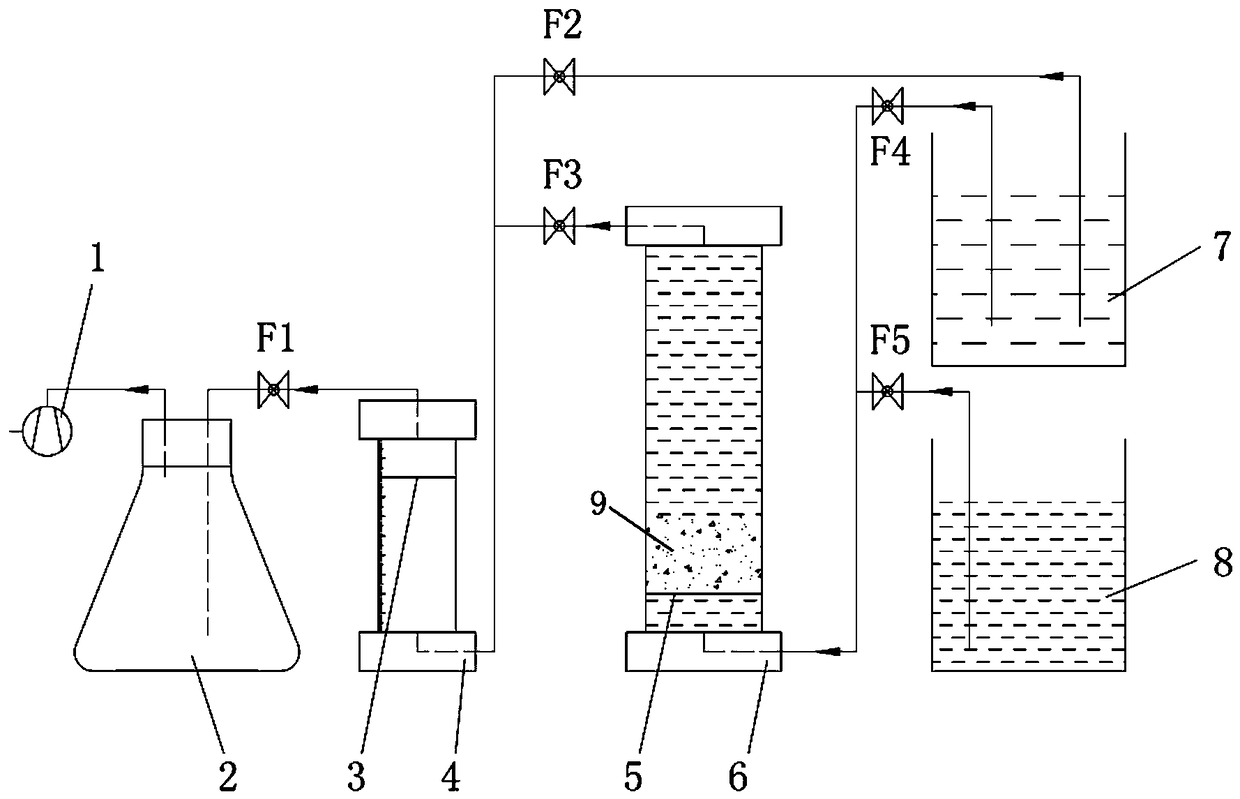

[0023] Embodiment 1: A kind of mud slag carrying capacity measuring device, see figure 1 , including vacuum pump 1, vacuum bottle 2, measuring cylinder 4, mixing cylinder 5, water tank 7 and mud tank 8.

[0024] The mud tank 8 is connected to the bottom of the mixing cylinder 6 through a pipe, the top of the mixing cylinder 6 is connected to the bottom of the measuring cylinder 4 through a pipeline, and the top of the measuring cylinder 4 is connected to the vacuum bottle 2 through a pipeline, and the vacuum pump 1 is connected to the vacuum bottle 2 through a suction pipe. ; Between the mud tank 8 and the mixing cylinder 6, between the mixing cylinder 6 and the measuring cylinder 4, between the measuring cylinder 4 and the vacuum bottle 2, valves F5, F3, and F1 are respectively provided; on the upper part of the measuring cylinder 4 A filter screen 3 is provided, and a filter screen 5 is provided at the bottom of the mixing cylinder 6, and the upper part of the filter screen ...

Embodiment 2

[0027] Embodiment 2: a method for measuring mud slag carrying capacity, comprising the following steps:

[0028] (1) Use the mud and slag-carrying capacity measuring device in Example 1 to measure, first configure the mud and muck with a predetermined ratio, place a certain amount of mud in the mud tank 8, put the weighed muck 9 into the Enter the upper part of the filter screen 5 in the mixing cylinder 6, and fill it with mud; open the valves F3 and F5 on the mud pipe, close the valves F2 and F4 on the water pipe, and connect the various parts in the device correspondingly;

[0029] (2) Turn on the vacuum pump 1, pump the vacuum bottle 2 to a certain degree of vacuum, and then open the valve F1. At this time, the mud starts to carry the muck from the mud tank 8 through the mixing cylinder 6 into the measuring cylinder 4, and passes through the filter in the measuring cylinder 4. 3 Discharge into vacuum bottle 2 after filtration;

[0030] (3) When the mud in the mud tank 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com