Method for optimizing parameter match between suspension system and damping element of hub-driven electric vehicle

A technology for electric vehicles and in-wheel drives, which is used in electrical digital data processing, design optimization/simulation, computing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

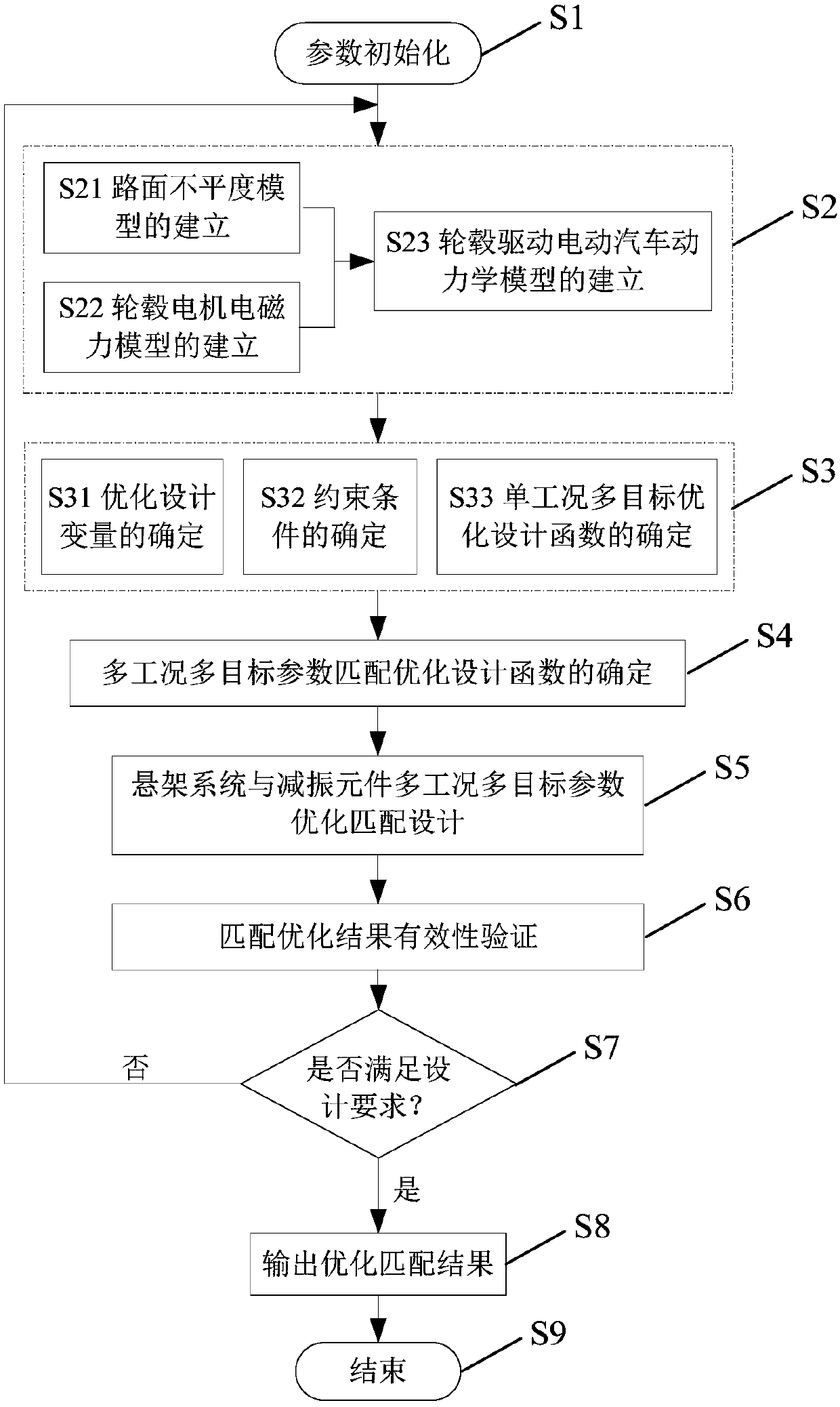

[0012] Such as figure 1 As shown in the flow chart, the method for optimizing the design of the suspension system of the wheel hub-driven electric vehicle and the parameter matching of the damping element proposed by the present invention includes: S1 parameter initialization; S2 establishment of the dynamic analysis model of the wheel hub-driven electric vehicle; S3 single working condition Determination of multi-objective optimization design objectives; S4 Determination of optimal design functions for multi-objective parameter matching in multiple working conditions; S5 Optimal matching design of suspension system and damping components in multi-working conditions and multi-objective parameters; S6 Validity verification of matching results; Design requirements; S8 outputs the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com